It’s summer, and it’s hot. No doubt, if you have an air-conditioned facility, your electric bills are headed someplace north of the top of the Eiffel Tower. HVLS (high volume, low speed) ceiling-mounted fans can reduce climate control costs, in particular when your facility is already air-conditioned.

Reduce Cooling Costs with HVLS Fans

Tags: heat stress, heat exhaustion, industrial fans, cooling, fans

Posted in Safety & Ergonomics|

Storage Efficiency: Shelves vs. Modular Drawers vs. Flow vs. Vertical Carousels

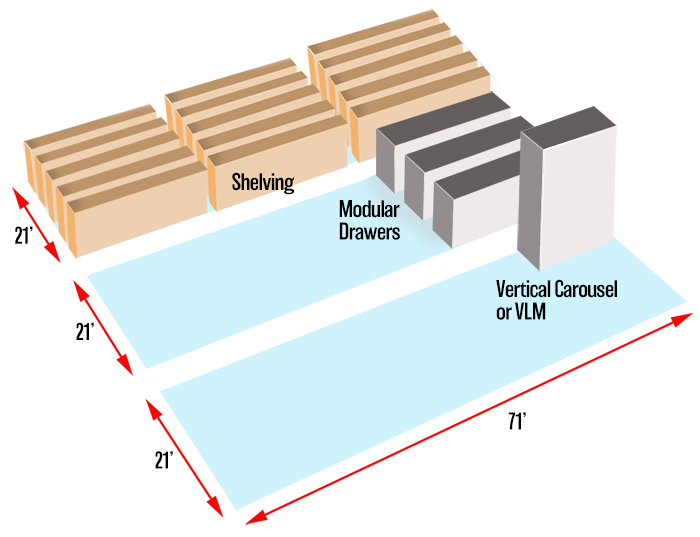

Storage systems are designed for different goals, but space efficiency is always important for growing and evolving warehouses and manufacturing facilities. Which storage equipment suits you, your application, product and needs?

Above: a visual comparison of space utilization featuring various methods. The vertical carousel provides the same amount of storage space as several rows of shelving or modular drawer storage. In this instance, the carousel saves over 1,400 square feet of floor space compared to shelving. Flow racks also compare favorably to shelving in terms of space utilization.

Tags: warehouse storage, space savings

Posted in Space Optimization & Planning|

Staged Shipments at Risk for Pilferage

The everyday stuff that hits many shipping docks may not be as organized, or to such a scale, but any operation that stores, ships or receives valuable items is at risk of being hit – or is already being hit to some degree. In the above case, an organized group of thieves working at a shipping dock would simply wait until after a supervisor finished checking outbound shipments and add more to them. Since the shipments sat on the docks for 90 minutes, it gave the pilferers plenty of time to work on this. They would place extra cases onto staged pallets and those would ship out on trucks driven by colluding drivers. The next day, the drivers would sell the extra product for cash and split the proceeds with their warehouse accomplices.

Tags: security, Industrial Security, inventory control

Posted in Security|

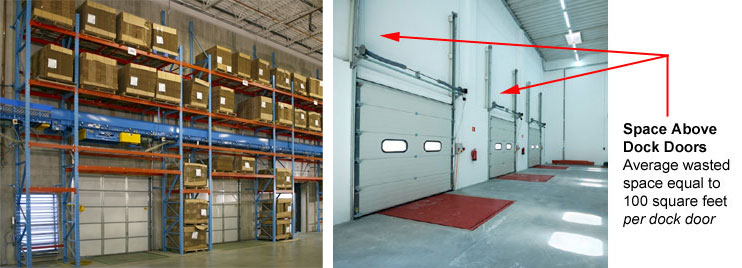

What’s the Most Useless Space in your Warehouse?

Next time you’re standing there wondering where you’re going to put an inbound shipment while your dock is stacked with empty pallets, look at those doors (or at the void above them) — the copious space between the top of the doors and the ceiling is unused. Multiply each door by that amount of space, and in many operations, we’re talking serious amounts of unused square footage.

The easy solution: find a use for it with over-dock-door storage. You can’t really rack heavy stuff up there without some significant structure. The best thing to consider is empty pallets, which take up a ton of room and are relatively lightweight. And usually, they’re all over the floor and always in your way. Empty pallets clutter up the shipping & receiving docks or can take up positions in your racks that would be better suited to full pallets of finished goods or incoming shipments.

Tags: Material Handling, Pallet Rack, space savings, industrial safety, dock doors, pallets, warehousing

Posted in Space Optimization & Planning|

Limiting Access to your Dock & Warehouse Areas

Leaving a dock door open all day is an invitation to have someone stroll your aisles, check out your inventory, and perhaps take something. Most busy operations, particularly in good weather situations, leave those doors open. Often, the crew is busy with actual work; they don’t have the time to monitor visitors, delivery drivers, service providers, and every other person who strolls in.

Tags: Material Handling, security, wire security cages, Industrial Security, wire partitions

Posted in Docks & Shipping|

How to Position Workbench & Station Supplies for Order Pickers and Packers

There isn’t enough room at your average industrial workstation. In fact, many order pickers, packers, shippers, and other professionals might tell you that you could have a 10′ long workbench, and they’d still be squeezed for space. In a busy operation, it’s a constant battle between availability of materials and space for doing the actual work. So what’s the solution? A larger workbench top?

Tags: order fulfillment, industrial safety, workstations, ergonomics, workbenches

Posted in Storage, Organization & Workstations|

More with Less: That’s Material Handling

Achieving more with less is a core goal of most businesses. In the warehousing and industrial world, that means building more, shipping more, doing more – controlling more – with fewer resources. The typical issue is labor in many of these operations. It takes people to run a shipping operation, and plenty of them.

“In economically challenging times like now, you’re being asked to produce more per person than ever,” said Cisco-Eagle’s CEO, Warren Gandall. “You’ve probably had to let people go. You may have shut down some areas, cancel contracts, cut a shift, and take the steps necessary to emerge from this downturn. But the big question is, how do you emerge stronger?”

Tags: Material Handling, lean manufacturing, supply chain operations, warehouse productivity, labor costs

Posted in Material Handling|

Wire Security Cages: Welded vs. Woven

With the focus on plant security the last few years, it’s little wonder that companies are outfitting their warehouses with security partitions and cages for high-value inventory, restricted access areas, tool cribs, and other places where more physical control of the property is needed. They are superb in these functions, keeping tools, components and inventories safe for a relatively low cost vs. other kinds of security measures.

Tags: security, warehouse storage, theft prevention, inventory control

Posted in Security|

Gravity Conveyor: How Many Skatewheels do You Need?

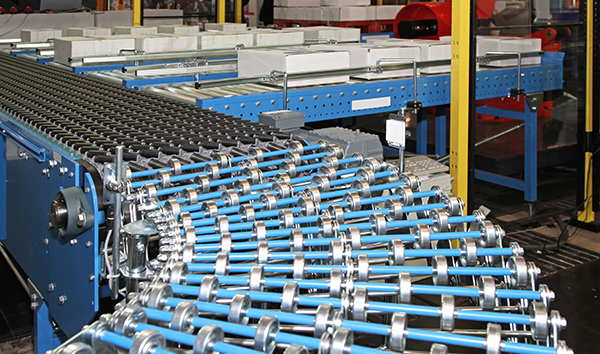

Gravity skate wheel conveyor is probably the most economical conveyor option around for quick, portable movement of lightweight boxes, totes, or trays.

You see it used in shipping & receiving areas, in assembly operations, or as a transitional piece between workstations and powered conveyor lines. You can even slap casters on it for a conveyor that can be rolled in & out of use areas. We even plug it into gravity flow racks to create heavier-duty, FIFO flow storage.

For such a simple piece of conveying equipment — in fact the simplest — errors can and do crop up when it’s ordered incorrectly.

Tags: Conveyor, warehousing, Material Handling, Hytrol

Posted in Conveyor Optimization|

Warehouse Space Savings: Consolidate from Shelf Bins into Modular Storage

This is a series of posts we’ll be making about saving space in your facility. There are plenty of ways to better utilize space, and some of them might fit your circumstances while others certainly won’t. In today’s challenging business climate, it is particularly critical to use space wisely in your facility.

Tags: warehousing, materials handling, saving space, modular storage systems

Posted in Space Optimization & Planning|