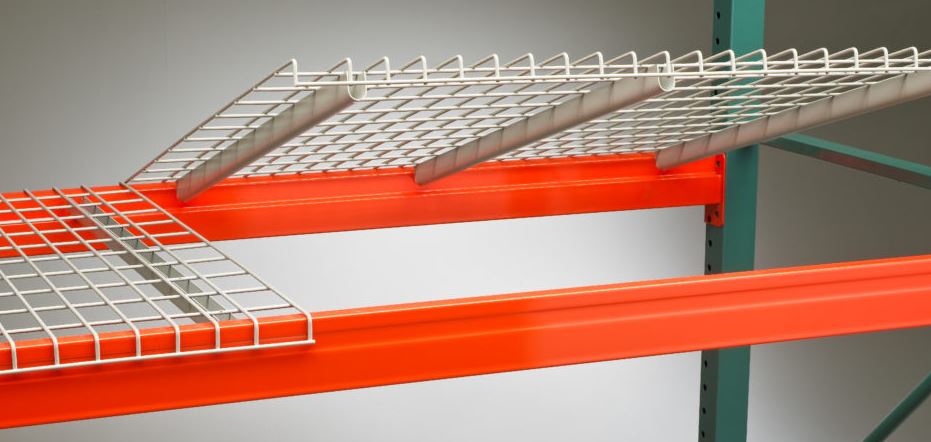

The Material Handling Industry of America recently announced that the RMI (Rack Manufacturers Institute) has certified several manufacturers of wire rack decking “R-Mark” compliant, meaning that these companies have conformed to the Institute’s testing and utilization standards.

Read the rest of this entry »