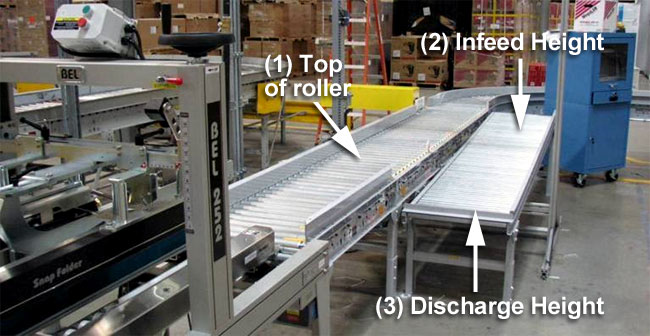

Conveyors–as we’ve discussed–have two major costs:

- The cost of conveyor hardware, which should include installation.

- The cost of operations, which should include maintenance, repair and energy consumption.

When you invest in capital equipment, you should be as focused on operational costs as purchase price. Part of that is extending the life of your conveyor system. How can you make sure you get the most out of your conveyors?