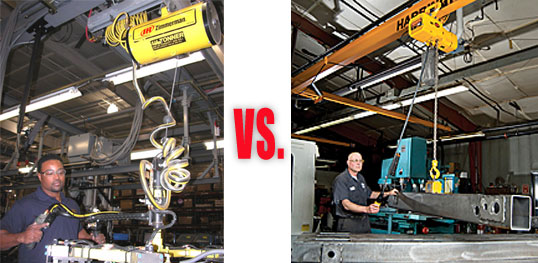

Lifting systems vary widely in type, capacities and sizes. Each is created to meet job-specific requirements of load capacity, cycle times, and lift range. Handling accuracy and smoothness are also considered. The two types of lifting systems addressed here are air balancers and chain hoists. They do essentially the same job: lifting an item into the air either from storage or a flat surface. So which might work for you?