Reducing steps and wasted time

How many steps do your floor managers take going back and forth to the computer and print stations in the plant as they do their jobs? How much time does all that walking take over a year’s time? How much more work could be done if computers and printers could go where they do? If you’re managing materials going to and from storage, all that travel time is taking valuable people assets away from what should be their primary function. Read the rest of this entry »

Tags: ROI

Posted in Warehousing & Distribution|

Waste might be the most critical measure for manufacturing operations – waste of labor, materials, time and money. Many companies are faced with nearly constant pressure to cut costs and increase efficiency, even as demand spikes. This means reducing costs without compromising quality or throughput. What are some things you can do to balance these needs?

Read the rest of this entry »

Tags: cost-of-goods, lean manufacturing, ROI, Cost Reduction, assembly

Posted in Manufacturing|

Manufacturing skills gap. Talent shortage. Shifting workforce demographics. What are the trends?

Call it what you will, but the fact remains that the U.S. manufacturing industry faces a pressing issue in the coming years if current worker retirement rates continue to accelerate and projections for industry expansion prove accurate. Research from the Manufacturing Institute and Deloitte indicates there could be as many as 2 million unfilled manufacturing jobs by 2025, up from initial estimates of 600,000. As noted in a Huffington Post article on the research findings, retirement and rapid industry growth are the two driving factors contributing to the skills shortage.

To get a better sense of how the industry is addressing the challenges (and potential opportunities) associated with the increasing skills gap, we recently conferred with industry partners, leaders, and subject matter experts.

Read the rest of this entry »

Tags: Automation, warehousing, Manufacturing, labor, skills gap

Posted in Manufacturing|

Your conveyors are the unsung hero of your facility, delivering product quickly and efficiently at the push of a button (or automatically in many cases) where it’s needed, when it’s needed. Most people don’t think about their conveyors and automated equipment much, but if it breaks down, you suddenly can’t think of much else. You simply can’t afford downtime when material handling equipment is delivering your core business.

Read the rest of this entry »

Tags: Conveyor, service, conveyor maintenance, repairs

Posted in Conveyor Optimization|

Do areas of your facility require constant temperatures? Are your employees dealing with significant seasonal temperature variations? These situations all require special conditions – often conditions that are hard to control with people and equipment moving in and out all the time. Let’s examine some climate control options outside the world of HVAC equipment.

Read the rest of this entry »

Tags: high volume low speed, high velocity, industrial fan, climate control, air circulation, destratification, ventilation, heating, work environment, cooling, fans, high-speed doors, mesh door, HVLS

Posted in Safety & Ergonomics|

Scene: a typical, busy warehouse

A fulfillment center with row upon row of pallet racks. Eight dock doors occupy one wall of the building, some for receiving, some for shipping. Pick workers work in the rack aisles pushing carts and pallet jacks loaded with picked orders. Other pick workers have empty totes on carts for pulling orders. Fork trucks stock pallet rack and pull bulk stock for large orders. Dock doors are left open much of the time, even when there’s no trailer at the dock.

How many potential safety risks can you envision in this scenario? How do you prevent those from happening?

Read the rest of this entry »

Tags: technology, safety sensors, motion detection, infrared

Posted in Safety & Ergonomics|

Somewhere in your facility, there may be a place where someone frequently shouts “shut the door!”

Perhaps you have operations that require maintaining temperatures within certain limits. There may also be areas heavy-traffic areas where a conventional overhead door’s slow lift and close rates cause delays, slower throughput and cause reduced productivity from waiting on a door to open.

These are situations where a high-speed door may solve a variety of problems. From limiting airborne debris, dust and contaminant infiltration to temperature regulation, high-speed doors pick up the pace in your facility even as they limit the amount of exposure to negative environmental influences. They open and close so quickly that forklifts and people hardly need wait on the door in order to pass through the doorway. Let’s take a few minutes to explore the types and key features of high-speed doors.

Read the rest of this entry »

Tags: high-speed door, vinyl mesh door, aluminum frame, steel frame, stainless steel frame, self-repair, collision, forklift

Posted in Docks & Shipping|

Incentive programs are surprisingly common for industrial operations, and they can produce significant savings, quality increases and improved employee satisfaction – if the program is built correctly. In manufacturing, assemblers are often incentivized for quality and speed. In warehousing, it can be reduced product damage, pick rates, error rates or any number of other categories. When companies build out these programs, there are opportunities to create great value. How are companies going about this?

Read the rest of this entry »

Tags: bonus programs, personnel, labor, ROI, industrial, Incentives, warehouse workers

Posted in Manufacturing|

Things get a little messy sometimes in most industrial facilities. Or a lot messy.

Areas where sprays and aerosols are used aren’t friendly to the rest of the operation, but they also need to exist in the same facility. Perhaps thermal zones are needed where there was once plenty of space. Welding stations may be in areas more highly populated with other workers. Amongst all these considerations is also the fluidity of your operations as the company grows and changes. Are permanent solutions (walls) the right answer?

Read the rest of this entry »

Tags: curtain walls, welding screens, acoustic panels, thermal walls, privacy screen, vinyl walls

Posted in Safety & Ergonomics|

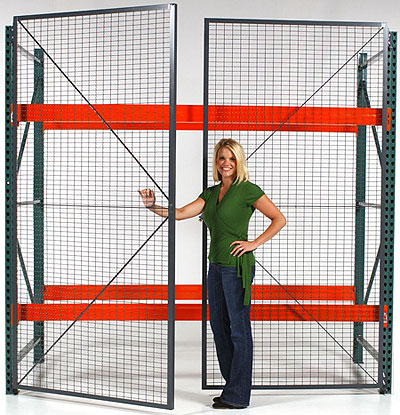

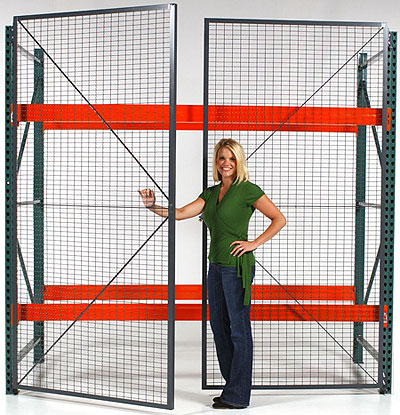

Warehouse security is sometimes slighted – other than perhaps exterior door locks and perhaps alarms. Security professionals will tell you that security is substantially about access to desirable items. How can you limit it? Let’s take a look at security equipment that can reduce temptation and help to keep vandals away from expensive exterior equipment.

Read the rest of this entry »

Tags: security cabinet, truck, security products, wire cage, wire partition, woven, welded, mesh, expanded steel

Posted in Security|

Read our customer reviews