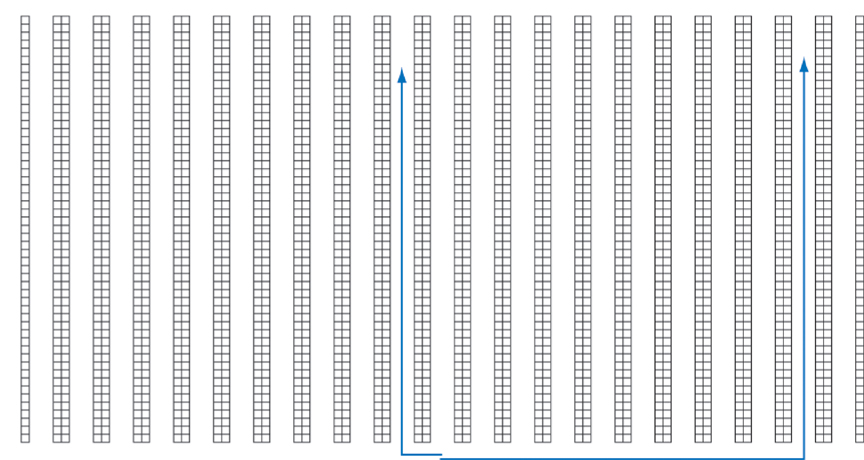

When you look at your next live roller conveyor system, it’s smart to look at new advances. Hytrol’s e24 conveyor is one of the most important new product introductions in many years. It’s difficult to understate how this conveyor can enhance operations, but here is a quick summary of the advantages.

Video: 24-Volt Roller Conveyors “Simplify Everything”

Tags: Hytrol, conveyor systems, roller conveying systems, e24

Posted in Conveyor Optimization|

Curtains and Dividers Help Retain Climate, Protect Products

When I was a kid, on rainy days my friends and I used kitchen chairs, old blankets and lots of clothespins and built our own special space for imaginary adventures. Our rag-tag shelter was temporary, but gave us the sensation of being in our own little world. Frequently, in manufacturing and warehousing facilities, work zones and independent departments need separation from the larger whole for either safety or autonomy purposes, and there are products out there that answer those needs. Products like curtain walls, acoustic walls, thermal barriers and welding screens. Read the rest of this entry »

Tags: warehouse space savings, curtain walls, acoustic, barrier, thermal, strip door, plastic, vinyl, welding, screen

Posted in Safety & Ergonomics|

You Must Control Access to Your Facility

Above: a driver security cage, which allows entry into a dock area door, but restricts access within the facility

It’s difficult enough to handle the people who are supposed to be in your plant every day, much less visitors. Even those you invite.

The problem has two components: safety and security. From a safety standpoint, you have no idea how an untrained guest might behave. That guest may not know which machines are dangerous. He may not know to use your specified pedestrian walkways, wear steel toe boots, or stay clear of running conveyors. He doesn’t have your safety training. From a security standpoint, guests can be problematic from a number of angles. A plant visitor who has access to storage areas has access to inventory. With even the cheapest of phones now having good cameras and video built in, a guest may photograph something you don’t want made public. That guest could also damage something, accidentally or otherwise. There are lots of wrinkles.

Tags: Safety & Ergonomics, Industrial Security, plant safety

Posted in Security|

Order Picking: Optimizing and Storing Slow Movers

The focus when it comes to order picking is usually (and justifiably) on the fastest-moving product. You slot your warehouse for fast movers. You pareto-focus on the 20% of the product that generates 80% of the business, as you should. But it’s also useful to consider the slow-moving inventory and pick locations. Simply putting the slowest movers in the least accessible area may make them consume more order picking time and storage space than necessary.

Tags: order fulfillment, Industrial Shelving, carton flow racks

Posted in Order Picking & Fulfillment|

Innovations in High Density Storage

Ever find yourself wondering how you can get more out of your pallet rack? Do you have goods that take up very little space, but your pick operations don’t call for entire pallets full of the product? Then you might need to look at ways to achieve more density in your storage, and we’ve recently found a gem of a product that can help you out. It’s called Dynamic High Density Storage and it’s made by SpeedCell.

Tags: warehouse storage, space savings, storage, industrial storage, distribution center, Order Picking & Fulfillment, Warehouse Management, warehousing, Pallet Rack, order fulfillment

Posted in Pallet & Warehouse Racks|

The Wonder of Robotic Palletizing

I recently attended an ESOP event at a specialty paints and stains company. During the tour of their plant, I got to see a robotic palletizing system in operation. I was impressed. Standing about 6 to 8 feet away from the action, I watched as it placed 5-gallon cans of paint in rows of 3 stacked 3 high. Each row was offset from the previous one, so that optimum pallet space was used. As the robot picked up cans off the conveyor belt using a vacuum end effector, it placed them precisely on the pallet. Then, it slightly dropped down and “bumped” them to make sure they seated onto the row below. That action made me chuckle as I considered what a profoundly human act that was – a little hip action to make sure the cans seated correctly.

Tags: lean manufacturing, industrial safety, palletizing, ergonomics, Robotics, Time-savings

Posted in Automation, Labor & Efficiency|

5 Common Pallet Rack Mistakes

When it comes to warehouse storage, pallet racks provide an optimal, easy-to-maintain solution. They’re the most common way of storing pallet loads in the world, and they’re used in the vast majority of warehouses, manufacturing facilities, commercial operations and even retail stores. Whether you’re dealing with selective, pushback, drive-in or other types of racks, the issues are frequently similar.

Safe pallet rack operation involves understanding how to properly use racks; an otherwise safe rack can become dangerous and expensive if used incorrectly. Here are 5 common mistakes people make with pallet racks—and what you can do to ensure you don’t make any of them in your warehouse.

Tags: Warehouse Management, pallet racks

Posted in Pallet & Warehouse Racks|

5 Heavy-Duty Shelving Solutions to Help You Maximize Storage Capacity

When it comes to the storage of industrial equipment, products, and parts, you need a reliable heavy-duty solution. Whether you work in a warehouse, shop, office, or manufacturing facility, a proper system of organization is essential to the way that you keep records, manage inventory, solve problems, and care for your tools.

Here’s a look at 5 industrial shelving solutions that can help you maximize your facility’s storage capacity, ultimately resulting in greater efficiency and workplace productivity: Read the rest of this entry »

Posted in Storage, Organization & Workstations|

Avoid Common Warehouse Layout Mistakes

It’s not easy to understand when facility layout is causing significant problems for an operation.

The way the warehouse is planned and laid out can affect everything in a warehouse or distribution facility. You may be suffering from over-forecasted demand for product and under-forecasted need for square footage. Executives may not fully understand what it takes to receive, store and ship orders. What are some of the more common problems when it comes to facility layout?

Tags: 3PL, warehouse storage, Third Party Logistics, facility layout, ecommerce

Posted in Space Optimization & Planning|

The Fork-Free Warehouse

http://www.cisco-eagle.com/c-1577-conveyor-guardrail.aspx

See Amanda’s White Paper as well.

Posted in Warehousing & Distribution|