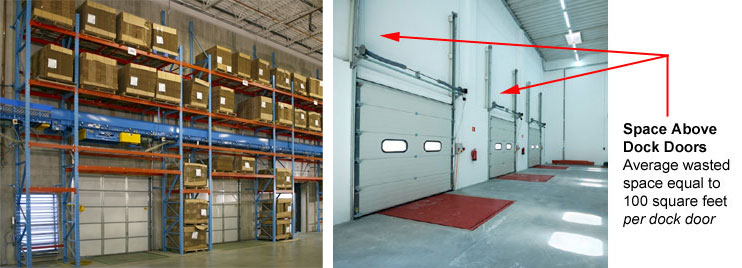

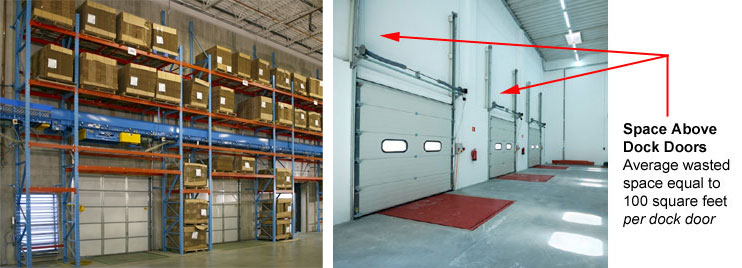

Next time you’re standing there wondering where you’re going to put an inbound shipment while your dock is stacked with empty pallets, look at those doors (or at the void above them) — the copious space between the top of the doors and the ceiling is unused. Multiply each door by that amount of space, and in many operations, we’re talking serious amounts of unused square footage.

The easy solution: find a use for it with over-dock-door storage. You can’t really rack heavy stuff up there without some significant structure. The best thing to consider is empty pallets, which take up a ton of room and are relatively lightweight. And usually, they’re all over the floor and always in your way. Empty pallets clutter up the shipping & receiving docks or can take up positions in your racks that would be better suited to full pallets of finished goods or incoming shipments.

Read the rest of this entry »