Studies indicate that order pickers spend too much time walking. Distribution center employees routinely spend more than half their day walking, not picking orders, packing orders, or replenishing stock. They’re going from point to point, burning man hours getting where they need to be, not working. And that’s the average — for really poorly designed operations, it’s worse.

As they tire, workers pick slower, pick less accurately, and work more dangerously — almost a zombie like situation! Every bad thing that can happen in a warehouse operation is amplified, the more time employees spend walking.

Check out our most recent Info-graphic, “Walking is the Walking Death of Order Picking Productivity” for more information on ways you can combat this issue.

More information:

Tags: order fulfillment, lean warehousing, ergonomics

Posted in Order Picking & Fulfillment|

Retail distribution facilities have multiple options for shipping product to store locations. They can send full pallets which must be unwrapped, unloaded, and stocked at the store location. They can send packed carts that can easily be rolled onto store floors and stocked at the point of sale. What method works best?

Read the rest of this entry »

Tags: warehousing, order fulfillment, Retail distribution, Safety & Ergonomics

Posted in Order Picking & Fulfillment|

Cliff Holste at Supply Chain Digest (opens in a new window) has a good piece on ways to improve picking productivity.

Distribution centers will benefit from emerging automated case picking technologies, but those don’t fit for every operation, at every level. They’re also expensive upgrades, so your ROI has to be considered as well.

Read the rest of this entry »

Tags: warehousing, order fulfillment, distribution center, ROI, Order Picking & Fulfillment, Warehouse Management

Posted in Order Picking & Fulfillment|

There isn’t enough room at your average industrial workstation. In fact, many order pickers, packers, shippers, and other professionals might tell you that you could have a 10′ long workbench, and they’d still be squeezed for space. In a busy operation, it’s a constant battle between availability of materials and space for doing the actual work. So what’s the solution? A larger workbench top?

Read the rest of this entry »

Tags: order fulfillment, industrial safety, workstations, ergonomics, workbenches

Posted in Storage, Organization & Workstations|

Be sure your floor can handle a structure – and all the weight or activity planned for that structure

We’ve created an informative article you should check out if you are thinking of installing a mezzanine in your facility.

When implementing an Industrial Equipment Platform (mezzanine) be sure that you are not putting too much stress or weight on the floor of the building. Too much weight will cause the floor to crack – or worse. This article tells you how to calculate the correct load capacity and column spacing for any new structural mezzanine project. Floor capacity depends on the thickness of the concrete, but that’s not the end of the story. It also matters how much the soil underneath the slab will compress.

Click “Calculating Mezzanine Floor Capacities” to get the whole story…

Tags: industrial storage, productivity, work platforms, warehousing, Material Handling, order fulfillment, Mezzanines

Posted in Mezzanines & Industrial Platforms|

Three areas – picking, packing and returns – incur anywhere from 60% to 80% of labor costs in your typical distribution operation. 60% of the average pickers’ time is spent walking. Not picking, not packing, not checking for quality and accuracy – walking. This is an activity that cannot add value to your operation or to your customers, so you should strive to eliminate it whenever possible. Not only does it waste time, it makes people tired, and tends to cause a loss in focus and can increase error rates.

Read the rest of this entry »

Tags: order fulfillment, labor, product slotting, carton flow racks, ergonomics

Posted in Order Picking & Fulfillment|

With the growing popularity of automating the palletizing function, we arranged an interview with vonGAL, a leading manufacturer who has the largest installed base of palletizers in the country. Bobby Edmond is vonGAL’s Director of Applications, and has been in the business for 25 years. He has seen applications in a wide range of industries, and in companies large and small. I asked him if he would take time to share his thoughts, and answer a few questions of interest to those that might be considering palletizing for the first time.

Read the rest of this entry »

Tags: Factory Automation, warehousing, Material Handling, shipping, order fulfillment, Palletizers, palletizing

Posted in Automation, Labor & Efficiency|

As interest continues to grow in automated palletizing, let’s take a brief look at a few of the issues surrounding these applications.

Over the next couple of months, I’ll be providing a handful of blog postings relative to palletizers. We will begin with what is driving the growth in the use of these products, then a look at basic systems, cost estimates, what you can expect from a properly applied palletizer system, and then share specifics from a couple of actual implementations in distribution centers. If you are experienced in palletizer systems, you will likely be familiar with much of what is covered here. If you are new to palletizing, or considering your first system, hopefully, this information will help you understand what the issues are and how you can navigate them.

Read the rest of this entry »

Tags: Palletizers, palletizing, ergonomics, Factory Automation, warehousing, Material Handling, shipping, order fulfillment

Posted in Automation, Labor & Efficiency|

Walk into any order fulfillment operation, and you will see gravity flow rack.

The reason is obvious–it’s one of the best ways to pick orders utilizing first-in, first-out principles. It used to be that there was one kind of the stuff, the plastic-wheel tracks, but these days the choices are more diverse than ever. For the most part, these flow rack types act the same; they decline toward the picker and boxes or totes or even larger components flow toward him. They’re restocked from the rear and picked from the front onto a takeaway conveyor line, a cart, workstation, or another step in the process.

Read the rest of this entry »

Tags: distribution center, Unex, Keneco, Conveyor, picking systems, warehousing, Material Handling, Hytrol, order fulfillment, Supply Chain, carton flow, gravity flow rack

Posted in Order Picking & Fulfillment|

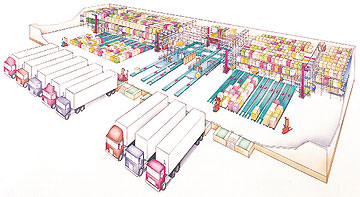

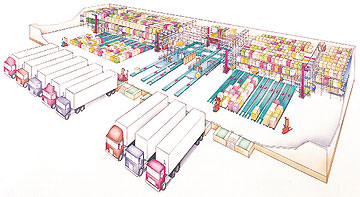

This is the third in a series of articles on cross-docking

If you started from scratch, many might simply build a cross-dock facility with a much shallower depth than most warehouses. A depth of a hundred feet or so, with incoming product on one side that can be easily moved a short distance and loaded on the other side to an outbound truck. Most of us must deal with an existing facility, many times a large square box which is not generally the preferred layout. However, as long as the existing facility has a sufficient quantity of dock doors, yard space, and an adequate footprint, you may be fine.

Read the rest of this entry »

Tags: advanced shipping notice, order fulfillment, Supply Chain, cross dock, Cross Docking, dock layout, conveyor systems

Posted in Space Optimization & Planning|

Read our customer reviews