I recently attended a product training class on high volume low speed fans, and a statistic was thrown out to the audience that really got me thinking. A NASA study, Compendium of Human Responses to the Aerospace Environment*, showed that worker productivity falls significantly for every degree over an optimum temperature of about 72 degrees. If the temperature hits 85 degrees in the workplace, productivity drops by 18% and accuracy a walloping 40%.

Read the rest of this entry »

Tags: noise, lighting quality, ergonomics, Safety & Ergonomics, worker environment, temperature comfort, fire safety, air quality, hearing loss

Posted in Safety & Ergonomics|

In manufacturing & distribution, safety is an area of top concern, for both the protection of workers and financial ramifications for companies. We spent some time at ProMat with Kelly Kamlager from Ladder Industries to examine the importance of safety and compliance for industrial companies.

Read the rest of this entry »

Tags: OSHA, Safety & Ergonomics, hiring, warehousing

Posted in Safety & Ergonomics|

Above: the edge of this pick module, which leads to a fall of over 20 feet, is guarded by a series of pallet flow swing gates.

When companies install storage platforms, the hustle and bustle of a busy working day can soften safety processes–a kind of soft that might lead to a hard and very expensive landing. Here are some ways you can reduce issue with work platform falls.

Read the rest of this entry »

Tags: Safety & Ergonomics, guard rail, handrail, mezzanine gate, pedestrian safety, pedestrian gate, Space Optimization

Posted in Mezzanines & Industrial Platforms|

Fork lifts are the mules of the industry, and we expect them to just power up and run when we need them to, but there are some very important safety aspects that should be taken care of before every shift. Safety steps that lengthen the service life of the vehicle, assure the vehicle operates as it should, and helps make it more visible to others working in the same space with the forklift. Read the rest of this entry »

Tags: Safety & Ergonomics, forklift, inspection, check levels, fork truck

Posted in Safety & Ergonomics|

In the last 200 years 70% of jobs done by American workers have been replaced by automation – and during the next century we will see another automation revolution that replaces 70% of American jobs–again.

Tags: Automation, ergonomics, Safety & Ergonomics, Robotics, workers force

Posted in Automation, Labor & Efficiency|

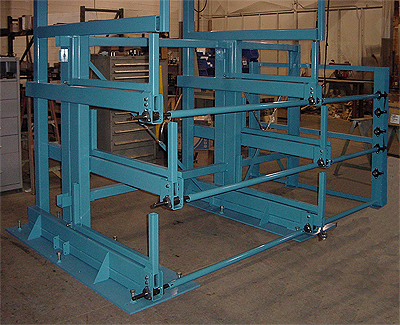

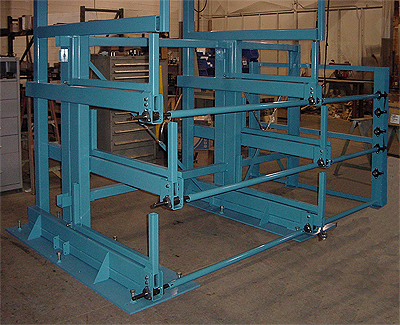

If you’ve got conduit, tubing, rebar, pipe or bar stock, you need cantilever rack – period. Get it off the floor, off of standard shelving and pallet rack, and put it somewhere you don’t have to fight with it each time you need some. If you’re really smart, you’ll put it where overhead lift equipment can get to it – because once you get it stored right, you’ll wonder what the heck you were thinking earlier.

Read the rest of this entry »

Tags: Safety & Ergonomics, cantilever rack, crank out shelving, ergonomic, heavy duty cantilever rack

Posted in Pallet & Warehouse Racks|

Choosing guard rail can be confusing unless you understand clearly what kinds of conditions you are protecting against and what assets you are protecting. Whether it be fall protection for workers or asset protection from industrial vehicle usage, there is a guard rail that fits that need.

Read the rest of this entry »

Tags: Safety & Ergonomics, guard rail, hand rail, guarding systems, warehouse safety

Posted in Safety & Ergonomics|

Is this an unevenly distributed load? Concentrated load?

Line load? Point load? Load of something really heavy?

We have stressed this before: rack loads aren’t just simple weight vs. structure. The dimensions, shape, and size/density of the load as it sits on storage racks is absolutely critical to safe, effective warehouse storage. Our friends at Nashville Wire recently released an excellent piece that helps define the load types and how you can avoid incorrect or unsafe rack loading.

Read the rest of this entry »

Tags: Pallet Rack, industrial storage, Safety & Ergonomics, storage rack

Posted in Pallet & Warehouse Racks|

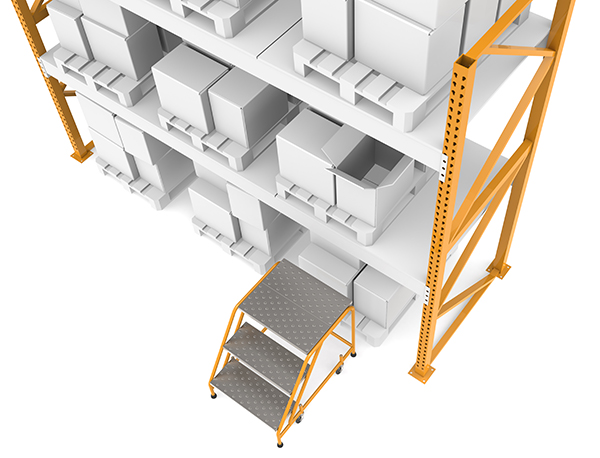

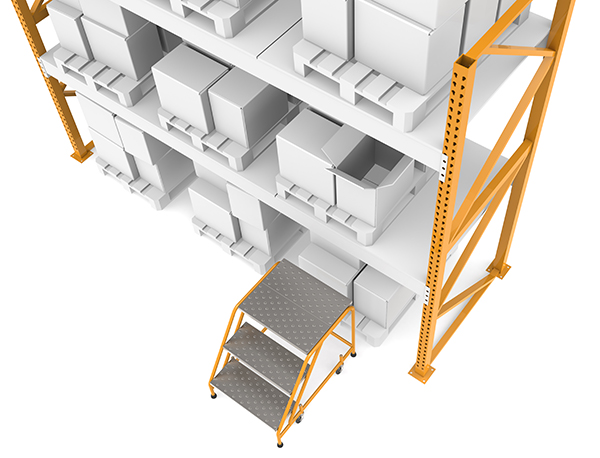

To save time, people sometimes climb pallet racks to pick orders or do other things. This should never happen. While it’s faster to climb than it is to bring a rolling stair ladder or a forklift in to do it right, it’s dangerous and counterproductive. Do it long enough and there will be injuries.

Read the rest of this entry »

Tags: warehouse rack, plant safety, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|

According to OSHA, training is the key to forklift safety, and there is fundamental agreement on that. Training can and does make a serious dent in the high injury rates suffered due to industrial traffic. Training must happen, and it must be repeated. But that begs this question: Why has training failed to move the needle when it comes to serious forklift related injuries? The numbers seem to have stabilized at an average of 100 deaths per year, and have stayed consistently at that level for years.

Read the rest of this entry »

Tags: industrial accident prevention, forklift safety, Safety & Ergonomics, traffic management

Posted in Forklift - Pedestrian Safety|

Read our customer reviews