I received a newsletter the other day that really hit home during this busy Christmas season. It was about keeping warehouse order pickers motivated in their work and I thought, “That’s really key during peak seasons when highly stressed workers can get burned out quickly.” So, how do you keep order pickers moving when they’re already under the gun?

Read the rest of this entry »

Tags: worker satisfaction, motivation, performance improvement, warehousing, order fulfillment, worker safety

Posted in Order Picking & Fulfillment|

Ever find yourself wondering how you can get more out of your pallet rack? Do you have goods that take up very little space, but your pick operations don’t call for entire pallets full of the product? Then you might need to look at ways to achieve more density in your storage, and we’ve recently found a gem of a product that can help you out. It’s called Dynamic High Density Storage and it’s made by SpeedCell.

Read the rest of this entry »

Tags: order fulfillment, warehouse storage, space savings, storage, industrial storage, distribution center, Order Picking & Fulfillment, Warehouse Management, warehousing, Pallet Rack

Posted in Pallet & Warehouse Racks|

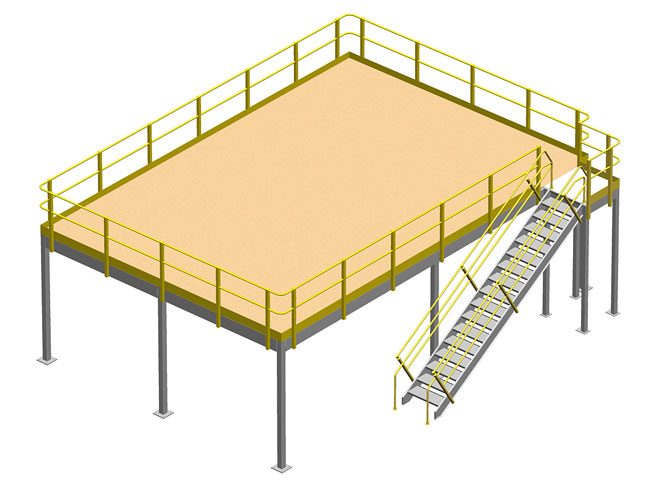

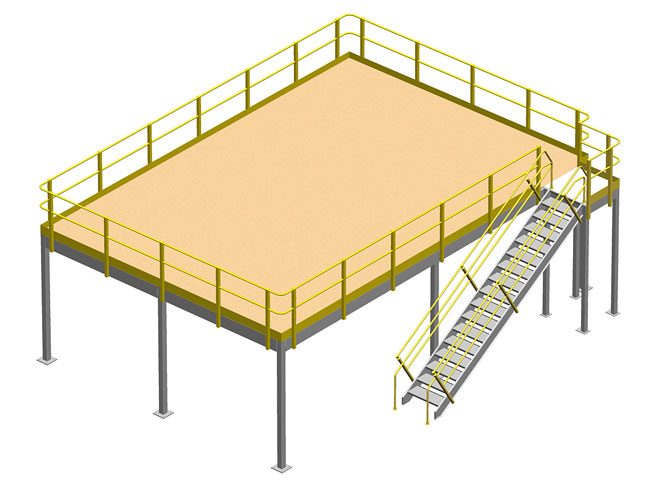

What a difference a name can make.

People tend to call any elevated platform a “mezzanine” in this industry, but that may be a mistake. When you are installing or otherwise specifying a platform, you need to be aware that the word “mezzanine” can cost you money and cause headaches when applied incorrectly.

Read the rest of this entry »

Tags: warehousing, Building Permits, Mezzanines, taxes, Space Optimization

Posted in Mezzanines & Industrial Platforms|

The warehouse. The office.

Sometimes it’s as if one doesn’t exist to the other. As one of our customers told us, “it’s like we have two companies here, and one doesn’t know what the other is up to.”

But when you’re trying to operate better, it’s impossible to separate the two functions. Decisions can be made in one area that can impact the other severely, so communication and cooperation are vital. Too bad it doesn’t always work that way. How can you improve it?

Read the rest of this entry »

Tags: Warehouse Management, warehousing, labor, ROI

Posted in Warehousing & Distribution|

OSHA has recently released a guide to safety incentives, disincentives, and reporting issues. It’s worth a quick read if you manage a manufacturing, warehousing, or industrial facility.

This document focuses on reporting/non-reporting workplace injury issues. OSHA says that “Reporting a work-related injury or illness is a core employee right, and retaliating against a worker for reporting an injury or illness is illegal discrimination under section 11(c).” Of course, smart companies want to know if there are unsafe conditions or practices. But what if your safety rewards program is discouraging employees from reporting incidents, or even near-misses?

Read the rest of this entry »

Tags: warehousing, OSHA, Manufacturing, industrial safety, Safety & Ergonomics

Posted in Safety & Ergonomics|

In a fast-paced distribution center, there is plenty of forklift traffic, moving conveyors, packing machines, carousels, and dock doors. Same with manufacturing; you have all kinds of production machinery, welding (human and robotic), and heavy material being handled, stacked, or processed, along with the forklifts and other handling equipment. It’s hard enough to keep your own people – the ones who should know the lay of the land – safe in these environments. But what about visitors who haven’t had the benefit of your safety training and the situational awareness that your employees develop over time?

Read the rest of this entry »

Tags: warehousing, Manufacturing, industrial safety, pallet racking, Safety & Ergonomics

Posted in Safety & Ergonomics|

In warehouse & manufacturing operations, things get broken. They break in a number of ways, and it’s expensive. You’ve probably seen product broken or damaged in amazing and improbable ways if you’ve been in this business for any length of time. We had a client once buy a bunch of mismatched, used industrial shelving (not from us), only to see it collapse and dump thousands of tiny aircraft components on the floor. It had to be swept up and discarded since it was all mixed up and visually impossible to sort.

Those are extraordinary examples, but everyday inventory damage that cost “only” a few hundred or thousand dollars can savage your bottom line.

Read the rest of this entry »

Tags: customer service, product damage, inventory control, damaged goods, warehousing

Posted in Warehousing & Distribution|

We see two kinds of operations that have utilized AisleCop® forklift safety gate systems. The first are those companies who have defined traffic plans and are looking to prevent possible accidents in high-risk, limited-visibility, or heavy-traffic aisles. They foresee potential accidents and are taking measures to prevent them. The second kind are companies who have had an incident, or a near-miss.

Read the rest of this entry »

Tags: warehousing, warehouse safety, ROI, forklift safety, AisleCop

Posted in Forklift - Pedestrian Safety|

One easy way to gauge a warehouse or manufacturing plant’s effectiveness is to check how clean it is. Cleaner facilities are more productive, tend to be safer and tend to be more organized.

Whether your facility features gleaming floors or just keeps debris from packaging materials, pallets and accumulated junk under control, being cleaner is well worth the time investment. People who work in a disorganized facility where things just feel sloppy won’t work as well. They may make more errors. They won’t have pride in the operation. An inch of dust on rack beams or beneath conveyor legs sends a message to workers. You don’t need a sparkling facility with floors so clean you could have lunch on them, but a well-lit, organized, pleasant place to work can be helpful in employee attitudes and retention.

Read the rest of this entry »

Tags: warehouse cleanliness, organization, warehousing

Posted in Warehousing & Distribution|

Retail distribution facilities have multiple options for shipping product to store locations. They can send full pallets which must be unwrapped, unloaded, and stocked at the store location. They can send packed carts that can easily be rolled onto store floors and stocked at the point of sale. What method works best?

Read the rest of this entry »

Tags: warehousing, order fulfillment, Retail distribution, Safety & Ergonomics

Posted in Order Picking & Fulfillment|

Read our customer reviews