- Systems & Automation

-

Shop Online

- Shop Online

- Automation & Robotics

- Barriers & Rails

- Cabinets & Lockers

- Carts, Trucks & Vehicles

- Casters & Wheels

- Containers, Totes & Bins

- Conveyors

- Dock Equipment

- Drum & Barrel Equipment

- Forklift Accessories

- Gravity & Carton Flow

- High-Speed & Vinyl Doors

- Ladders

- Lifts, Cranes & Hoists

- Mezzanines & Platforms

- Modular Buildings

- Packaging and Shipping Equipment

- Pallet Handling

- Racks

- Safety & Ergonomics

- Security & Partitions

- Shelving

- Stainless Steel Equipment

- Workbenches & Stations

-

Shop Online

-

Safety & Ergonomics

Safety SensorsAisleCop® Forklift Safety GatesProximity Detection Systems Shop All

-

- Service & Maintenance

- Safety Automation

- Resources

- About Us

- Contact

Medium Duty Gravity Roller Conveyor (beds only)

Choose between two different roller finishes and capacities

Get Quote- 1.9" diameter steel rollers - 16 gauge galvanized or 9 gauge unplated

- Galvanized has better rust resistance, unplated has higher capacity

- 7/16" axles for added strength and capacity

- Straight and curve sections available for each type

| Model No. | Overall Width | Type | Size | Roller Style | Roller Centers | Price | ||

|---|---|---|---|---|---|---|---|---|

| 19GSR-13-2.25-10L | 16" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $602.00 |

|

|

| 19GSR-13-3-10L | 16" | Straight | 10' | 16 ga. galvanized | 3" | $468.00 |

|

|

| 19GSR-13-4.5-10L | 16" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $365.00 |

|

|

| 19GSR-13-6-10L | 16" | Straight | 10' | 16 ga. galvanized | 6" | $315.00 |

|

|

| 19GSR-15-2.25-10L | 18" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $642.00 |

|

|

| 19GSR-15-3-10L | 18" | Straight | 10' | 16 ga. galvanized | 3" | $491.00 |

|

|

| 19GSR-15-4.5-10L | 18" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $385.00 |

|

|

| 19GSR-15-6-10L | 18" | Straight | 10' | 16 ga. galvanized | 6" | $329.00 |

|

|

| 19GSR-17-2.25-10L | 20" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $681.00 |

|

|

| 19GSR-17-3-10L | 20" | Straight | 10' | 16 ga. galvanized | 3" | $514.00 |

|

|

| 19GSR-17-4.5-10L | 20" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $404.00 |

|

|

| 19GSR-17-6-10L | 20" | Straight | 10' | 16 ga. galvanized | 6" | $345.00 |

|

| Model No. | Overall Width | Type | Size | Roller Style | Roller Centers | Price | ||

|---|---|---|---|---|---|---|---|---|

| 19GSR-13-2.25-10L | 16" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $602.00 |

|

|

| 19GSR-13-3-10L | 16" | Straight | 10' | 16 ga. galvanized | 3" | $468.00 |

|

|

| 19GSR-13-4.5-10L | 16" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $365.00 |

|

|

| 19GSR-13-6-10L | 16" | Straight | 10' | 16 ga. galvanized | 6" | $315.00 |

|

|

| 19GSR-15-2.25-10L | 18" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $642.00 |

|

|

| 19GSR-15-3-10L | 18" | Straight | 10' | 16 ga. galvanized | 3" | $491.00 |

|

|

| 19GSR-15-4.5-10L | 18" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $385.00 |

|

|

| 19GSR-15-6-10L | 18" | Straight | 10' | 16 ga. galvanized | 6" | $329.00 |

|

|

| 19GSR-17-2.25-10L | 20" | Straight | 10' | 16 ga. galvanized | 2-1/4" | $681.00 |

|

|

| 19GSR-17-3-10L | 20" | Straight | 10' | 16 ga. galvanized | 3" | $514.00 |

|

|

| 19GSR-17-4.5-10L | 20" | Straight | 10' | 16 ga. galvanized | 4-1/2" | $404.00 |

|

|

| 19GSR-17-6-10L | 20" | Straight | 10' | 16 ga. galvanized | 6" | $345.00 |

|

Width

Conveyor width is measured in two ways; overall width (OAW) and between rail width. Overall width includes the width of the frame, which is 1.5" on either side of the rails. This means that the between rail width would be 3" less than the overall width of the conveyor. Keep this in mind when determining what width of conveyor you need to meet your package requirements.

Length & Supports

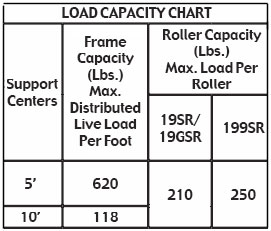

Roller conveyor is available in 5 foot and 10 foot lengths for straight sections. The length of the conveyor along with the number of supports underneath greatly determine its load capacity. In most applications, supports should be placed in either 5 or 10 feet intervals depending on the weight of the product you are conveying. By installing a support every 5 feet, capacity of that section increases greatly; keep in mind though that no matter how close together you place supports, the roller axles themselves also have a capacity that should not be exceeded.

1-866-443-5648

© Cisco-Eagle 2024. All Rights Reserved