How to Adjust Conveyor Drive Chain Alignment and Tension

How to Adjust Conveyor Drive Chain Alignment and Tension

Get Service!

Your conveyor's drive chain and sprockets should be checked on a regular basis to insure proper tension, alignment and lubrication. Improper adjustment or lubrication may cause noise and/or extensive wear to the drive components, resulting in a shorter life cycle and decreased conveyor performance. The good news is that it's something you can easily adjust and maintain.

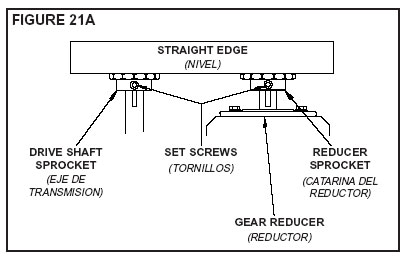

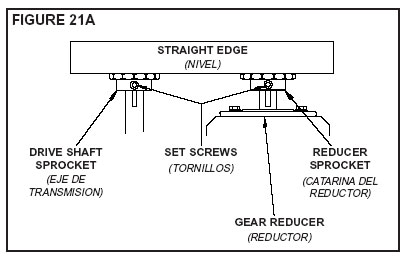

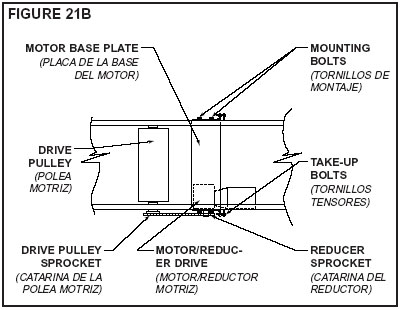

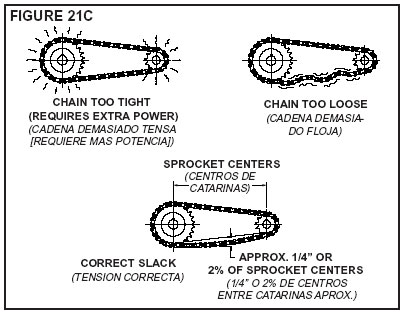

See illustrations (figures 21A-21C) below to help you with this information

To make adjust your conveyor:

- Disconnect and lockout power to the conveyor.

- Remove the chain guard.

- Check sprocket alignment by placing a straightedge across the face of both sprockets. The faces of the two sprockets should be square with the straightedge. If not, loosen the set screws in one or both sprockets and adjust as necessary to align the two sprockets. Re-tighten the set screws.

- To adjust chain tension, loosen the bolts that fasten the motor base to mounting angles on both sides. Tighten take-up bolts until desired chain tension is reached. Do not over-tighten. A good rule of thumb is 1/4" deflection in the chain between the sprockets. Make sure both sides are adjusted the same amount to maintain sprocket alignment. This can be measured at the take-up bolts. Re-tighten mounting bolts.

- Lubricate the chain per your maintenance instructions.

- Replace the chain guard.

- Re-connect power on to conveyor and run to test.

Caution: Never remove chain guards while the conveyor is running. Always replace guards after adjustments are made.

If you have questions about this procedure, please contact us. We will be glad to help you with the process, questions, or other concerns.