High-Density Pallet Shuttle Systems

Ideal for high-volume operations of single-SKU pallets and other intensive loading or unloading operations

Get QuoteIf your operation requires a high-density pallet storage and access solution, pallet shuttles could be the answer.

How it works

Shuttles are electrically powered and run on rails installed within the rack structure, and are one of the most efficient ways to reduce forklift use. In cases where a forklift must enter a deep storage lane, shuttles provide safer and more consistent access since forklifts can strike rack components deep in the system. Aside from the safety factor, they're fast—really fast compared to forklift access. They let you group your SKUs by channels instead of lane, creating a level of storage density and flexibility a drive-in system can't match.

Shuttles are controlled by an operator, who uses a simple tablet application powered by wi-fi connectivity.

Loading & replenishment

The shuttle places its pallet load in the first available free location, which efficiently compacts the pallets in any channel. This allows you to store pallet positions deeper than possible with standard racking systems, but also allows faster retrieval—operators are always picking from the very front position rather than driving into the structure.

Detailed gallery: pallet rack shuttle systems

Click on the thumbnails to see a larger image below.

Applications

- When you have a limited number of SKUs and a large quantity of pallets

- When you have a great deal of loading and unloading activity

- When you need to create storage buffers

- When you need high-density storage to fill the cube

- When you need to store pallets in significantly deeper configurations than drive-in or pallet flow systems

- When your storage space is particularly expensive, and reduced picking times are critical, such as in cold storage facilities

- When your warehouse must deal with seasonal spikes and unpredictable inflows and outflows

How the system is loaded

Place the shuttle

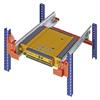

Place the shuttleOnce the rack system and shuttle channels are installed, your forklift places a shuttle into the special channels on each level of the rack bay. Shuttle channels are built to tight tolerances so that the shuttles fit easily and ride smoothly through the rack system.

Place pallets in the first position

Place pallets in the first positionAfter the shuttle is in the system, forklifts deposit pallets one at a time in the channel entrance. Pallets are rested on beams (not the shuttle's channel).

The shuttle fills your lanes

The shuttle fills your lanesWith the system's simple tablet controls, you send a command to the shuttle, which starts loading the rack, moving pallets into the rack structure. To do this, the shuttle glides beneath the stored pallet, then lifts it up so that it can be transported. Then, the shuttle rides to the first available location and sits the pallet back on the rack's rails in precise locations—usually the first available position. Sensors control the movement of the shuttle as it moves.

The shuttle fills the entire lane with pallets

The shuttle fills the entire lane with pallets The pallet shuttle returns to the front of the lane to transport the next pallet and repeats until the lane is fully stocked. Once the front position is filled, your forklift operator can remove the shuttle so that it can work on the next channel.