Your shopping cart is currently empty.

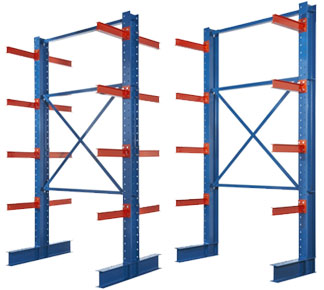

I-Beam cantilever rack provides a sturdy, reliable base on which to store heavy pipe, metal rod, and other long, heavy materials. It stands up to rugged use and comes in a wide variety of sizes and capacities. Units offered here are just a sample of possible configurations.

How to design your cantilever rack system

Determine the number and spacing of support arms using enough arms to prevent deflection of the load:

- The number of arms required equals the number of wood blocks needed to support load without deflection. Test for deflection:

- Place wood blocks evenly spaced on the floor under the load, starting with 2 wood blocks

- Add blocks at evenly spaced intervals under the load, until the load no longer deflects (or sags between wood blocks)

- Arm capacity required equals the Load weight divided by the number of wood blocks needed. '(2 blocks mean arm capacity required is 1/2 the load weight, 3 blocks equal 1/3 the load weight, etc.)

- Optimal width between uprights equals load length divided by the number of block supports needed (2 blocks means the centerpoint between uprights is 1/2 the load length, 3 blocks mean the uprights must be positioned at intervals equal to 1/3 of the load length, etc.)

- Correct design has product overhang at the end of the rack by 1/2 of the optimal upright width distance

-

Determine the arm length, which is:

- Equal to the load depth.

- The load does not hang over the end of the arm.

-

Determine the optimal upright height beginning with the base height:

Base Height

+ number of storage levels x load height

+ number of arm levels x arm height at widest point

+ number of storage levels x handling clearance (4" - 6")

= upright height-

- Be mindful your total height is within ceiling height and forklift height limits

- Your topmost arm level must be below the upright height top

- Contact us for current arm and base dimensions

-

-

Determine capacities needed:

- Arm capacity equals load weight divided by the number of arms per level (assuming load is to be evenly distributed)

-

Upright capacity equals the number of arms per side multiplied by the load per arm

- Load on base is not included in capacity

- Brace lengths equal the horizontal distance on center between uprights