Pallet Rack Upright 42D x 240H

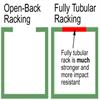

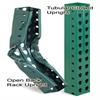

Store your inventory on safe, impact-resistant totally enclosed tubular upright frames

SKU: RTFBG042240

Manufacturer: Steel King

- Height: 240"

- Depth: 42"

- Columns: 3 x 3

- Weight: 140.0 lbs. ea.

Upright frames are 44 times more resistant to torsional fork truck impacts than open back designs

Many

new rack buyers opt for the SK2000-style tubular design, and users of existing

open back (roll formed) boltless rack replace damaged upright frames

with new SK2000 frames to lessen impact dangers and eliminate maintenance costs. Because SK2000 uses "tear drop" connections, these users

are able to upgrade while reusing their existing load beams. Frame has full

diagonal-and horizontal bracing throughout the upright frame height.

Many

new rack buyers opt for the SK2000-style tubular design, and users of existing

open back (roll formed) boltless rack replace damaged upright frames

with new SK2000 frames to lessen impact dangers and eliminate maintenance costs. Because SK2000 uses "tear drop" connections, these users

are able to upgrade while reusing their existing load beams. Frame has full

diagonal-and horizontal bracing throughout the upright frame height.

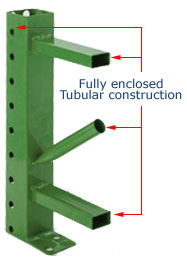

- A formed ridge on the column's face provides additional steel surface area, increasing cross-section strength and rigidity

- Closed, seamless tubing used for all components - columns, braces, and beams

- High-strength closed tubular design has 250% more frontal impact strength than a comparable open back column

- Welds between braces and column are full fillet welds, providing more strength than spot-welds on other rack systems.

- Frames feature a tapered keyhole connection slot, interchangeable with many other rack systems

- Holes are placed on the column's face, not the corners, minimizing strength loss

- Allows 2" vertical beam adjustments

- Heavy 10-gauge footpads are flush with the column's sides, allowing for full seating of floor level load beams

- Footpads are welded directly to the uprights, dispersing the column load more efficiently than conventional lighter footpads

- A formed ridge on the footpad allows for easy nesting of shim plates

- Multiple offset anchor holes on footpad allow for re-anchoring in cases where rebar interferes with anchoring.

RMI Certified

All SK2000 storage rack products are certified RMI 1997; confirming that it abides by the most stringent safety procedures. This means that the rack meets or exceeds industry safety standards; that it met an independent review and certification of manufacturer load tables; is compliant to a Global standard, and complies to the default standard for 2000 IBC.

Powder Coat Finishing

Powder Coat Finishing

SK2000 is painted with a high-durability powder coat paint

finish. Powder coated products offer better resistance to water and corrosion,

better gloss, hardness, and adhesion. In fact, Steel King powder coated products

give you:

- 60% greater resistance to solvents

- 74% greater resistance to salt sprays

- 94% greater resistance to impact

- Capacity chart - (PDF, opens a new window)

- Effect of heavy horizontal braces on impact resistance - (PDF, opens a new window)

- The impact of column shape on frontal and side impact resistance - (PDF, opens a new window)

Lead Time: 2-3 days + transit time

Contact Cisco-Eagle to get a Shipping Rate for this item