Accumulation Conveyor - 40'L, 24"W - 1.9" Rollers

Let cartons lightly touch for simple accumulation and reduced product damage

SKU: 50.10.24.40

Manufacturer: Hytrol

How minimum pressure accumulation conveyor works:

The driving of the tread rollers on minimum pressure conveyor is accomplished with the top surface of a standard section endless V-belt. The strength and wear qualities of the tread rollers and this belt have been thoroughly tested for continuous duty. To maintain the driving of the tread roller, the pressure roller is mounted in spring-adjusted carriers which sense the required driving friction regardless of the length of the accumulated load. The pressure can be maintained constantly to give a 2% minimum back pressure in either forward or reverse direction.In the event of extreme changes in the load (weight of box or package), convenient knurled thumb adjusting nuts can be turned to accept a heavier load. This method eliminates the need for selecting proper tension spring holes in trigger mechanisms or jogging cleats on driving belt and eccentric (off center) tread rollers. By maintaining a constant minimum pressure on the tread rollers, long loads may be conveyed, accumulated, or stopped in the conveyor at any point using very little motor horsepower and giving practically no pressure between boxes or packages.

Width

Accumulation conveyor width is measured in two ways; overall width and between rail width. Overall width includes the width of the frame, which is 1-1/2" on either side of the belt. This means that the belt width would be 3" less than the overall width of the conveyor. Keep this in mind when determining what width of conveyor you need to meet your package requirements.

Shipping

Conveyor is crated and shipped in 5ft and 10ft sections, depending on the overall length of the conveyor, and will need to be bolted together on-site. The drive assembly, reducer, and motor will shipped attached to one of these sections. Because these sections are unattached for shipping, the conveyor belt itself will also have to be attached onsite. Please note that this conveyor DOES NOT include electrical components or switches.

- Lead Time: 6 weeks + transit time

- Width: 24"

- Length: 40'

- Capacity: Max 150 lbs. per linear foot

- Color: Hytrol Green

- Overall Width: 24"

- Between Rails: 21"

- Length: 40'

- Section Type: Straight

- Model: 190-ACC

- Type: Accumulation

- Pressure: Minimum (2%)

- # of Supports: 5

- Bed: Roller bed with 6-1/2" x 12 ga. channel frame

- Rollers: 1.9" diameter galvanized tube

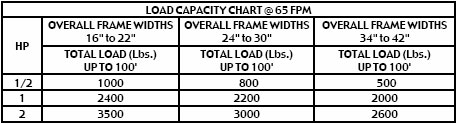

- Speed: 65 feet per minute

- Drive: Mounted underneath near center

- Drive Belt: Endless B-section aramid core

- Speed Reduction: Sealed worm gear C-Face speed reducer. Number 50 roller chain to drive shaft

- Return Take Up: 3-1/4" diameter x 1/2 bore flat idler has seven position adjustment

- Roller Spacing: 3" top roller spacing; 6" spacing for underside pressure rollers

- Bearings: Tread & pressure rollers have pre-lubricated ball bearings. Flange & pillow block bearings are sealed

- Cross Bracing: Rods with turnbuckles are fastened to underside of bed to provide alignment and insure product tracking

- Weight: 1751.5 lbs. ea.

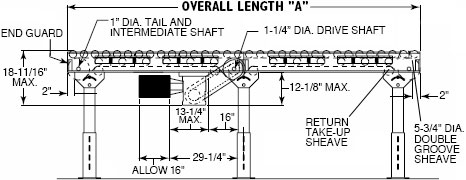

Side View

Capacity

- Specification Sheet - 190-ACC - (648 KB PDF, opens in new window)

- Installation and Maintenance Manual (8.4MB PDF, opens in new window)