Pallet Rack with Wire Decking - Adder, 3 Beam Levels - 144"w x 42"d x 192"h - 8020 Cap. Beams

Complete pallet rack units include heavy-duty wire decking

SKU: A42192BP-600-144-3-D

Manufacturer: Steel King

- W x D x H: 144" x 42" x 192"

- Type: Adder

- Beam Levels: 3

- Total Capacity: 21160 lbs.

- Beam Capacity: 8020 lbs.

- Configuration: 3 Level Adder

- Dimensions: 192"h x 42"d x 144"w

- Beams: 6 x SBRUG600-144

- Uprights: 1 x RTFBP042192

- Decking: 9 x N4246-3-1

- Weight: 693.8 lbs. ea.

- A limited number of complete racks are offered. If you don't see what you need, contact us - we specialize in pallet rack configuration

- Mix starters and adders to create longer rows of racking

- We can assist you with your rack layout - get exactly what you need to fit your space and load factors

- Add extra beam levels, accessories, or other options as recommended in the accessories section

- Durable, attractive powder-coat finish on all rack components Beams are poppy orange; frames finished in vista green

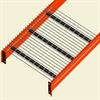

Wire

decking gives you the flexibility to store cartons, drums, and multiple pallet

sizes on the same rack beam

Wire

decking gives you the flexibility to store cartons, drums, and multiple pallet

sizes on the same rack beam

These racks come equipped with wire decking to allow maximum flexibility and increase the usefulness of the rack. If you don't see the size of rack you need, contact us - we can easily configure the exact racking you need.

- Economical for new installations and for upgrading your current rack system

- Decking provides greater structural strength than other materials—tough and durable wire construction with underlying metal supports

- Decking eliminates dust and debris build-up and improve air circulation

- Meets ANSI MH-26.2 standards

- Constructed from heavy-duty 4-Gauge wire

- Spacing between wires is 2" x 4", with 2½" x 4½" available (contact us for information)

Ultra-Strong,

seamlessly welded tubular beams

Ultra-Strong,

seamlessly welded tubular beams

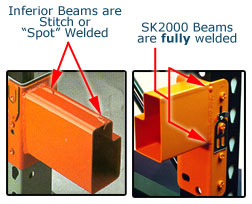

- SK2000 is a seamlessly welded tubular high-strength steel beam with full vertical fillet welds

- All beams are constructed of high-strength (60,000 p.s.i. minimum) steel.

- Beam connections feature a 3-rivet connection and safety lock per beam end for greater resistance to beam "tear out" than does a two-rivet connection

- Interchangeable teardrop & rivet beam

- You can easily replace your worn-out beams with SK2000 on most rack systems and brands

- Innovative 1/16" stiffening ribs built into the face of the beam give you higher capacities at a better price

- So easy to install that one man, without tools, can do it

- Steel King safety locks are an integral component of the beam. They are not shipped separately, reducing risk of loss or misplacement.

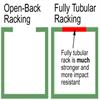

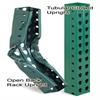

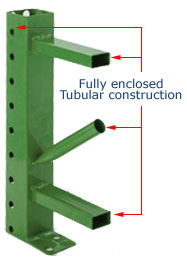

Upright frames are 44 times more resistant to torsional for truck impacts than open back designs

Many

new rack buyers opt for the SK2000-style tubular design, and users of existing

open back (roll formed) boltless rack replace damaged upright frames

with new SK2000 frames to lessen impact dangers and eliminate maintenance costs. Because SK2000 uses "tear drop" connections, these users

are able to upgrade while reusing their existing load beams.

Many

new rack buyers opt for the SK2000-style tubular design, and users of existing

open back (roll formed) boltless rack replace damaged upright frames

with new SK2000 frames to lessen impact dangers and eliminate maintenance costs. Because SK2000 uses "tear drop" connections, these users

are able to upgrade while reusing their existing load beams.

- SK2000 uses closed, seamless tubing for all components - columns, braces, and beams

- High-strength closed tubular design has 250% more frontal impact strength than a comparable open back column

- Welds between braces and column are full fillet welds, providing more strength than spot-welds on other rack systems.

- SK2000 frames feature a tapered keyhole connection slot, interchangeable with many other rack systems

- Holes are placed on the column's face, not the corners, minimizing strength loss

- Allows 2" vertical beam adjustments

- Heavy 10-gauge footpads are flush with the column's sides, allowing for full seating of floor level load beams

- Footpads are welded directly to the uprights, dispersing the column load more efficiently than conventional lighter footpads

- A formed ridge on the footpad allows for easy nesting of shim plates

- Multiple offset anchor holes on footpad allow for re-anchoring in cases where rebar interferes with anchoring.

RMI Certified

All SK2000 storage rack products are certified RMI 1997; confirming that it abides by the most stringent safety procedures. This means that the rack meets or exceeds industry safety standards; that it met an independent review and certification of manufacturer load tables; is compliant to a Global standard, and complies to the default standard for 2000 IBC.

Capacity Note

Total capacity listed requires an evenly distributed load and 64 inches of spacing between each beam level. Adding or subtracting beam levels from the configuration as shown will alter that capacity. Contact us if you have questions or concerns regarding this issue or any others, we'll be glad to help.

Capacity Note

Total capacity listed requires an evenly distributed load and 64 inches of spacing between each beam level. Adding or subtracting beam levels from the configuration as shown will alter that capacity. Contact us if you have questions or concerns regarding this issue or any others, we'll be glad to help.

- Steel King Pallet Rack User Manual - (4.31MB PDF - opens new window)

- The effect of the number of rivets on beam connection strength - (169KB PDF - opens new window)

- SK2000 vs. open back racks - (58KB PDF - opens new window)

- Effect of heavy horizontal braces on impact resistance - (160KB PDF - opens new window)

- The effect of column shape on frontal and side impact resistance - (787KB PDF - opens new window)