Air Balancer with ZA Controls, 1,400 lbs. Cap., 40" Travel

Easily raise, lower, rotate and move heavy loads while focusing on the job, not the weight

SKU: ZAW140040

Manufacturer: Zimmerman

- Cap. (Lbs.): 1400

- Travel (In.): 40

- Balancer Dia. (in.): 10+10

- Setup: Reeved Tandem

- Controls: ZA - Pendant style

- Max. Capacity @: 100 psi

- Hang angle: 3o

- Weight: 129.0 lbs. ea.

Precision, safety, adjustability make air balancers an excellent ergonomic handling method

Precision, safety, adjustability make air balancers an excellent ergonomic handling method

- Precise, strain-free positioning: Float leaves both of the operator's hands free to raise, lower, or shift the load with virtually no resistance. No more "hoist control" hit-and-miss spotting.

- Built in overhead protection ensures that the load being lifted cannot exceed the unit's maximum rated capacity for a given air pressure.

- Minimal cable recoil due to loss of load. If the load is accidentally lost, a spring-loaded centrifugal brake (Z brake) automatically stops rapid upward cable movement.

- Clear access to air-flow calibration controls allows quick, easy adjustment of the float.

- Low air consumption: Approximately 1/8 cfm is required per cycle. This is 50 times less than required by an air hoist, and means very low energy cost for a lot of muscle.

- Clean, oil-free operation: The pre-lubricated design eliminates air line lubrication and oil mist exhaust. It's ideal for food processing and clean manufacturing environments.

- Rugged reliability: For continuous duty with minimal maintenance, the Balance Air delivers cost-effective performance.

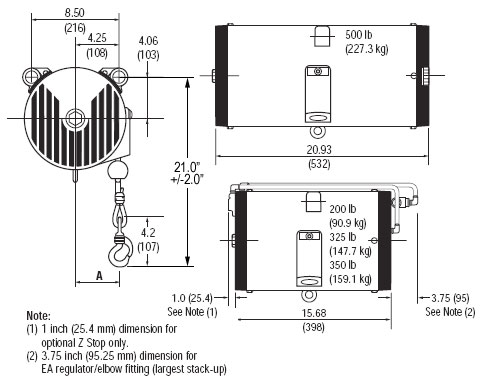

The optional Z-Stop (left) eliminates the downward drift of suspended loads or tools during shut down or at night when the air supply is shut off. The Z-stop will stop drift within 6 inches and put the Balance Air into a mechanically locked position, preventing damage to tools or objects below the suspended load.

The optional Z-Stop (left) eliminates the downward drift of suspended loads or tools during shut down or at night when the air supply is shut off. The Z-stop will stop drift within 6 inches and put the Balance Air into a mechanically locked position, preventing damage to tools or objects below the suspended load.

The included Z-Brake (right) adds safety by preventing violent retraction in the event of a sudden release or loss of load. The brake also eliminates excessive upward acceleration of an unloaded hook when the "up" button is employed to full depression.

The included Z-Brake (right) adds safety by preventing violent retraction in the event of a sudden release or loss of load. The brake also eliminates excessive upward acceleration of an unloaded hook when the "up" button is employed to full depression.

Important Air Balancer Capacity Notes

- Actual operating capacity is determined by available plant air pressure at the device (not at the compressor). Operating capacity decreases by 1% for every one psi (pound per square inch) below 100 psi inlet air pressure. For example, a balancer with 350 pounds capacity would have 175 pounds capacity at 50 psi (350 x 50%). To achieve maximum capacity, it's vital that your air sources are checked at the device, and routinely re-checked

- For lifting applications, working load should not exceed 80% of operating capacity

- For balancing applications, working load should note exceed 60% of operating capacity

- Working load includes part weight and handling device weight

If you are unsure about the capacity rating of a balancer and how it may apply in your facility, or with your intended load, contact us for assistance. We can help you configure precisely the right balancer for your application.

Suspension Kit Options

You may select any of the following suspension kits for your air balancer. All capacities are greater than 150 lbs.

| Suspension Kit | Compatible with | Rail Type |

|---|---|---|

| Ing Rand ZRS2 Steel Rail | Ingersoll Rand/Zimmerman | Steel |

| Ing Rand ZRS3 Steel Rail | Ingersoll Rand/Zimmerman | Steel |

| Ing Rand ZRA2 Alum Rail | Ingersoll Rand/Zimmerman | Aluminum |

| Unified ETA-8 Alum Rail | Unified | Aluminum |

| Demag KBK2L Steel Rail | Demag | Steel |

| Knight 8" Aluminum | Knight | Aluminum |

| Knight 8" Aluminum Anti Kick Back | Knight | Aluminum |

| Knight 6" Steel | Knight | Steel |

| Knight 7" Steel | Knight | Steel |

- Installation Guide (1.26 MB PDF, opens in new window)

- Maintenance Guide (5.62 MB PDF, opens in new window

- Parts List (2.26 MB PDF, opens in new window)

- Product Guide (16.55 MB PDF, opens in new window)

- Safety Info (1.55 MB PDF, opens in new window)

Lead Time: 8 to 10 weeks + transit time

Get Shipping Estimate