3.5" Gravity Roller Conveyor - 5' Long, 15" Between Rail Width, 6" Roller Centers

Non-powered gravity conveyor moves heavy materials quickly and economically, with little maintenance

SKU: 36SR-15-6-5L

Manufacturer: Hytrol

- Frame: Structural channel

- Roller Diameter: 3.5", 6" roller centers

- Width: 15" (between rail)

- Type: Straight, heavy duty

- Size: 5'

- Frame Construction: 5" x 6.7 lb. structural channel

- Roller Bearings: Steel inner-shield seals; grease-packed

- Roller Construction: 3.5" diameter x .300 unplated

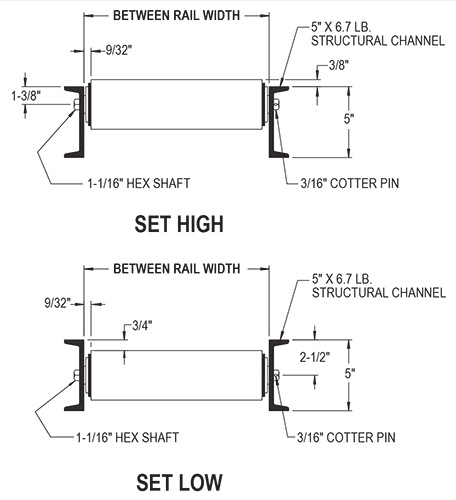

- Axles: 1-1/16" hex shaft with 3/16" cotter pin

- Couplings: Butt type for bolting sections together

- Roller Capacity: 1040 lbs. per roller

- Frame Capacity: 2500 lbs. maximum distributed live load per foot

- Floor Supports: HSF type available

- Weight: 276.0 lbs. ea.

Connecting Conveyor

Each section of conveyor has butt couplings on both ends. These ends can be bolted together between conveyor sections to create long conveyor lines. Joined sections must have support installed beneath the couplings.

Example: If your 15 foot conveyor line is made up of a 10 foot section and a 5 foot section, the minimum number of your supports you would need is 3; one under each end, and one beneath the connection. This configuration however would give your 10 foot section a lower capacity than the 5 foot section unless you placed an intermediate support under the 10 foot.

Length & Supports

Roller conveyor is available in 5 foot and 10 foot lengths for straight sections. The length of the conveyor along with the number of supports underneath greatly determine its load capacity. In most applications, supports should be placed in either 5 or 10 feet intervals depending on the weight of the product you are conveying. By installing a support every 5 feet, capacity of that section increases greatly; keep in mind though that no matter how close together you place supports, the roller axles themselves also have a capacity that should not be exceeded.

Roller Setting

Rollers may be set high or low within the frame. See diagram below:

- Specifications (566KB PDF, opens in new window)

![]() More on Gravity Conveyors (Product sizes, spacing, capacities, etc.)

More on Gravity Conveyors (Product sizes, spacing, capacities, etc.)

Lead Time: 6 weeks + transit time

Contact Cisco-Eagle to get a Shipping Rate for this item