Your shopping cart is currently empty.

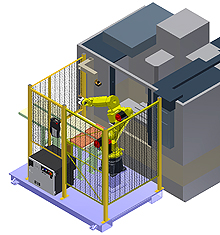

Robotic Machine Tool Tending System - Automated Load/Unload, 44 lb. Payload Cap.

Integrated vision and reliability in positioning for machine tool tending

SKU: M20IA-35M

Manufacturer: Fanuc

A complete automated system with infeed and outfeed conveyors, this vision guided robotic work cell is suitable for load and unload of one CNC machine. The six-way motion capability of the robotic arm allows positioning and orientation on all axis. The provided end effector has dual grip capability and is able to pick up articles, orient, and position them in the holder on the machine. When the machining cycle is complete, the robot then removes the milled piece and places it on the outfeed conveyor. Payload capacity: 20 kg (44 lbs.). Machine guarding barrier with one door included. Please call if you would like to customize this system.

- Type: M20iA/12

- End Effector: Dual Gripper

- Payload At Wrist: 20 kg (44 lb)

- Estimated Price: $100,000 - $110,000

- Robot: M-20iA/35M Fanuc Robot with System R-30iB Robot Controller and i-pendant, robot riser, system base

- Capacity: 20 kg. (44 lbs.) payload at the wrist

- EOAT: Dual gripper for (1) part size, controls and dress-out package

- Conveyor: (1) infeed belt conveyor, 5-ft. long, 12-in. wide; (1) outfeed belt conveyor, 6-ft. long, 12-in. wide; conveyor controls

- Engineering: System controls consisting of panels, drives, sensors, junction boxes, terminal blocks, and wiring as required for Fanuc supplied equipment; system Design and Controls engineering, Software development and debug, Project Management, and Manufacturing services

- Software: Handling Tool Robot Operating system software, Motion software package, PMC and Internet software package, Load/Unload Application software for (1) part size in one machine

- Machine Guarding: (1) area barrier with (1) access door

- Cabling: Fanuc I/O Link Kit

- Vision: iRVision 2D Guidance with (1) camera, camera mounting frame

- Testing: Choice of customer on Fanuc's floor or receipt of video of system integration, debug and acceptance testing

An excellent choice for:

- Assembly

- Dispensing

- Material handling

- Machine load/unload

- Material removal

- Waterjet cutting

- Laser cutting

- Machine tending

- Picking and packing

- Testing and sampling

Features and Benefits

- 6 degrees of motion

- plus or minus 0.10mm (1/254") repeatability

- 20 kg payload at wrist

- Large wrist moments and inertias for real-world EOAT's and workpieces

- Supplementary payload mount on J3 casting

- Pneumatic and electrical (8 DI/8DO) connections for EOAT on J3

- 2D vision cables from J1 to J3 as a standard option

- Compact with slim wrist and small footprint allows this robot to be used in tight places

- Robot can be installed with a floor, wall or ceiling mount

- Increased throughput due to fast joint motion

- No need for homing at start-up because robot has absolute encoder positioning

- Teach pendant has color graphics and is ready to link into your network

- 50 mm hollow wrist and upper arm is a built-in Solution Arm

- Compact package delivers performance and rigidity through an RV reducer and gear drivetrains

- System protected and improved with sealed bearings and brushless, maintenance-free AC motors

- M-10iA and M-20iA Series - (9.47 MB, PDF, Opens in new window)