Slider Bed Incline Conveyor - 18" W x 19' 10" L

Move products safely and efficiently between work levels

SKU: 35.10.18.20

Manufacturer: Hytrol

Click on the thumbnails to see a larger image below.

Incline Angle

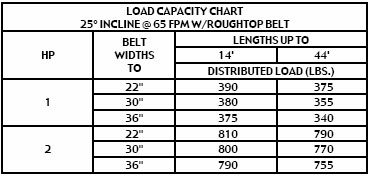

Conveyor height, speed, and capacities listed are applicable for an incline of 25 degrees. Any adjustments made to the angle of the incline may have an impact on all of these values. If you have a custom application of this conveyor and are unsure of how changes in the elevation angle may affect your workload, feel free to submit a Custom Conveyor Inquiry or call us at 1-888-877-3861.

Power Feeder and Double Nose-Over

Slider Bed Inclines and Roller Bed Inclines are fed from a 35-1/2" horizontal conveyor section that is bolted onto the incline bed. The feeder section is chain driven by the tail pulley of the incline. The top nose-over section is a 26" horizontal conveyor section that is bolted onto the tail end of the incline bed using a 12" intermediate section. The intermediate nose-over section allows for a smoother two-step transition of products moving from incline to horizontal. The double nose-over also provides up to a 30 degree incline adjustment.

Width

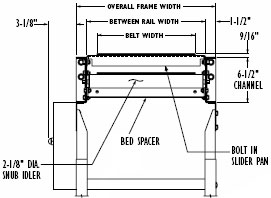

Belt conveyor width is measured in two ways; overall width (or bed width) and belt width. Overall width includes the width of the frame, which extends 3" to either side of the belt. This means that the belt width would be 6" less than the overall width of the conveyor. Keep this in mind when determining what width of conveyor you need to meet your package requirements.

Shipping

Conveyor is crated and shipped in 5ft and 10ft sections, depending on the overall length of the conveyor, and will need to be bolted together on-site. The drive assembly, reducer, and motor will shipped attached to one of these sections. Because these sections are unattached for shipping, the conveyor belt itself will also have to be attached onsite.

Length & Supports

Conveyor is available in 5 foot and 10 foot lengths for straight sections. Supports are required at the infeed end, discharge end, and at each intermediate bed connection.

The length of the conveyor along with the number of supports underneath greatly determine its load capacity. In most applications, supports should be placed in either 5 or 10 feet intervals depending on the weight of the product you are conveying. By installing a support every 5 feet, capacity of that section increases greatly; keep in mind though that no matter how close together you place supports, the roller axles themselves also have a capacity that should not be exceeded.

Please note that this conveyor DOES NOT include electrical components or switches.

- Lead Time: 6 weeks + transit time

- Overall Width: 18"

- Height (H): 7'-2"

- Length (B): 18'-3"

- Bed Length: 16'

- Overall Length: 19' 10"

- Belt Width: 12"

- Belt: Black Trackmate 120 Roughtop with PVC cover. Clipper lacing

- Bed: 12 ga. galvanized slider pan mounted in 6-1/2 in. x 12 ga. powder painted, formed steel channel frame. Standard 4 ft., 6 ft., 8 ft., and 10 ft. long sections bolt together with splice plates

- Double Nose-Over: A 26 in. long horizontal and a 12 in. long nose-over section provides a two-step transition of product from incline to horizontal. Provides up to 30° incline adjustment

- Low Pressure Feeder: Chain type driven from tail pulley of inclined conveyor. Supports not included in base price

- Center Drive: Located on the incline section. Chain guard located on left hand side

- Drive Pulley: 8 in. dia. with 1-7/16 in. dia. shaft at bearings, fully lagged

- Tail Pulley: 4 in. dia. with 1 in. dia. shaft at bearings, machine crowned

- Take Up Pulley: 4 in. dia. with 1 in. dia. shaft at bearings, machine crowned

- Bearings: Sealed, pre-lubricated, self-aligning, ball bearings with eccentric lock collar on drive shaft. Pre-lubricated ball bearings in tread rollers

- Speed Reduction: Sealed worm gear C-Face speed reducer. No. 50 roller chain to drive shaft

- Snub Idler: Adjustable 2-1/8 in. dia. or 2-1/2 in. dia. pre-lubricated ball bearings. Snub guards included

- Return Idler: Adjustable 1.9 in. dia. pre-lubricated ball bearings

- Motor: 1 HP–208/230/460/575V–3 Ph. 60 Hz. Totally Enclosed C-Face "SSB" Brake Motor (6 ft./lb.)

- Speed: Constant 65 FPM

- Capacity: Maximum load per linear foot of conveyor 100 lbs. NOT TO EXCEED capacity in chart.

- Weight: 1185.7 lbs. ea.

- Specs and Drawings - Model SBI - (648 KB PDF, opens in new window)

- Installation and Maintenance Manual (3.05MB PDF, opens in new window)