Sometimes more than the initial loadout is needed for the job

Studies of aircraft maintenance facilities show that traditional tool-crib arrangements, where technicians must queue and travel to and from a central storage location, can consume a large amount of manpower hours. This is where Hanel systems come into play.

The issue of transit and dwell time

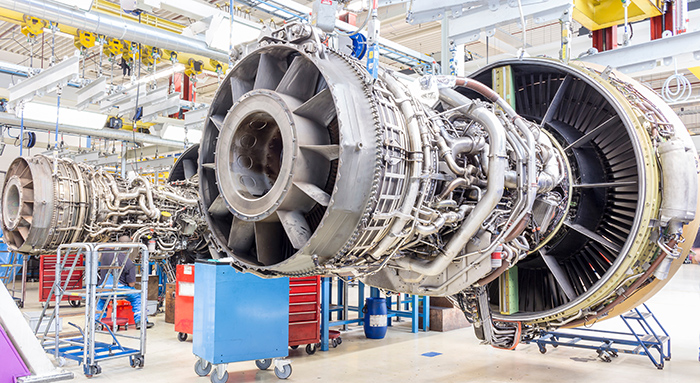

Waiting for parts to be picked from distant tool cribs or parts rooms, then transported to the engine bay injects non-value-added transit and dwell time that slows the process and amplifies downtime. Technicians are waiting while the clock ticks.

Studies of aircraft maintenance facilities show that traditional tool-crib arrangements, where technicians must queue and travel to and from a central storage location, consume a significant portion of manpower hours.

Position parts close to the point of use

Correctly positioned and governed goods-to-person technology like carousels and vertical lift modules place the parts—in great quantities and completely organized—in the close orbit of skilled technicians. They don't need a parts runner or paperwork to get what's necessary. They may only be steps away from what's required. And since this is 100% transparent and traceable, you'll know what parts where taken, where, by who, and why.