Carousels and vertical lift modules: ideal for aerospace

Carousels/VLMs are ideal for most aerospace facilities

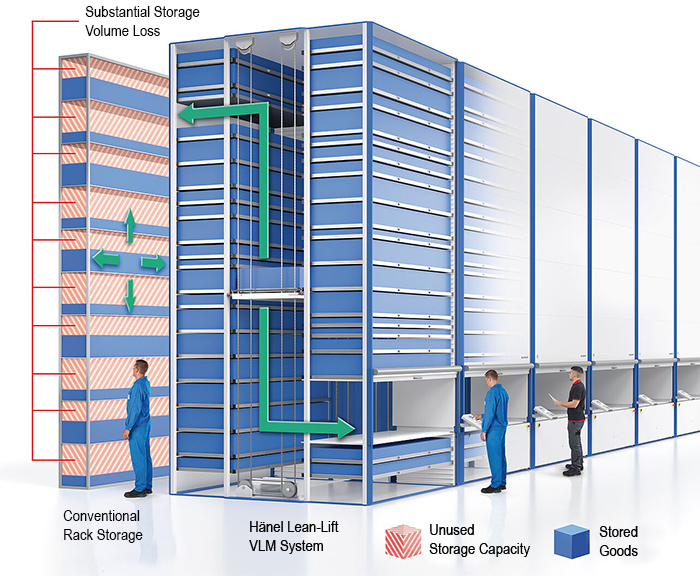

Aerospace facilities are typically built with high ceilings to accommodate aircraft, cranes and large assembly fixtures. Your vertical volume goes unused when storage is limited to low-profile shelving or racks. VLMs and carousels leverage overhead space, storing inventory from floor to ceiling.

Parts consolidation based on real height data

Hundreds of trays are consolidated into a single vertical footprint. Each tray is automatically measured, and the system uses intelligent algorithms to place items optimally based on height. See height sensors for more information

Storage density and speed in a fraction of the space

Instead of spreading horizontally across aisles, the carousels store everything in a vertical footprint and deliver components to ergonomic access points. Large quantities of tools, avionics modules, fasteners, consumables, or documentation using only a fraction of the footprint of shelving or modular drawer systems. See How Carousels and VLMs Optimize Space for more information.

Don't waste your tech's time: bring them the goods

Space savings in aerospace isn't just about recovering floor area—it's about creating shorter paths and more efficient workflows. Every foot of distance between storage and the point of use creates non-value time: walking, searching, transporting, and returning items. See Aircraft Engine MRO: Space and Time for more information.

Count on the Hänel x Cisco-Eagle partnership to optimize your process

For operators seeking to add new work bays, reduce aircraft-on-ground delays, expand production output or simply make better use of hangar or plant space, automated vertical storage is one of the most effective and proven tools available.