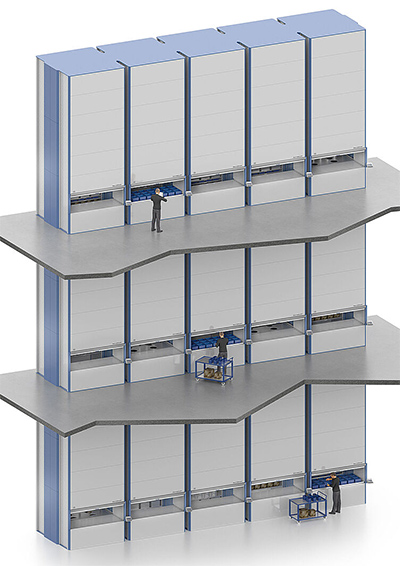

Use all your vertical space to its potential

In multi-level hangars or facilities with mezzanines, VLMs can pass trays through floor openings or deliver items to different elevations, enabling centralized storage that serves multiple work areas. In higher-bay hangars, this lets you build work platforms that can all be served by a single VLM. Back-shop locations like NDT labs, hydraulic repair shops, and component overhaul zones benefit from carousel and VLM configurations that separate controlled items, maintain cleanliness, and support batch picking for repair orders.

Technicians shouldn't need to walk across the hangar to fetch tools or wait for parts for remote storeroom picks from runners. Carousels and VLMs bring them the things they need directly to the access point at floor level. Work gets done the most efficient way.

Layout and integration to existing hardware and systems

Aerospace operations frequently use multi-level access. Many aerospace operations have multi-level mezzanines, work platforms, or parts access rooms. These elements mesh perfectly with carousels and vertical lift modules, since access points can be added to a single carousel at more than one vertical placement.

Integration with existing material-handling equipment is straightforward. Carousels and VLMs can interface with carts, lift tables or hoists, conveyors and AGVs/AMRs to create efficient part-flow paths from receiving to maintenance lines.

Aerospace operations frequently use use VLMs as the central node of a kitting operation, where parts are pre-staged for scheduled maintenance tasks and delivered directly to the bay.

It's about process simplification

Good processes strive for simplicity, and carousels deliver that for aerospace MRO operations. Whether installed beside an engine stand, within a tool crib, or in a centralized inventory zone, automated storage simplifies layout challenges and ensures that technicians always have critical items within reach. This improves throughput, reducing congestion, and supporting safer, more organized MRO operations.