The Anatomy of a Pick Module

What are the design factors?

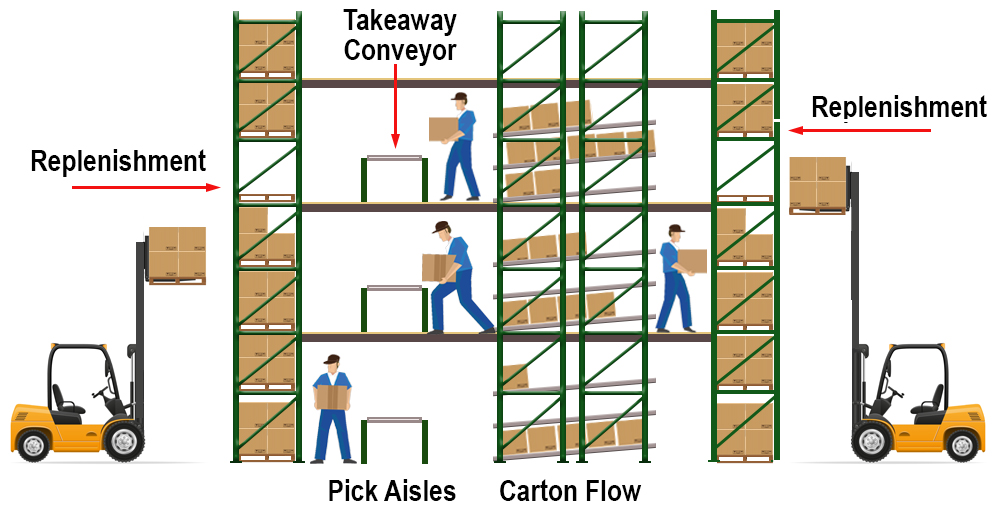

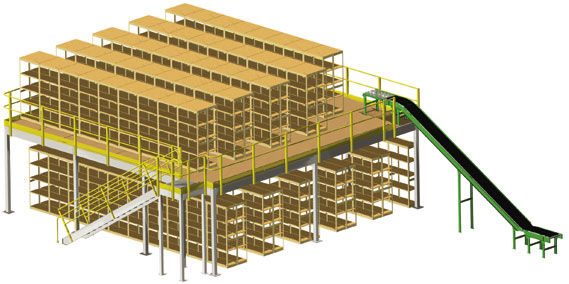

Pick modules support a range of warehouse activities, but their primary role is to increase the speed and space efficiency of order fulfillment operations. Configured with racks (which are usually the support structure), conveyors, flow storage, shelves and modular storage, they let you design the storage, fulfillment and picking strategy that fits your needs. Some pick modules are simple — really, just a shelf-supported mezzanine. Others combine automation and WMS systems for full systems integration.

When do you need a pick module?

Pick modules are common in modern distribution centers because they leverage existing space and reduce the time it takes to execute order picking processes.

- Multilevel modules let you optimize space by stacking pick aisles vertically. It’s more efficient and compact to utilize the vertical cube than to pay for climate control or administrate a complex picking operation that’s spread out and physically separated.

- Pick modules are ideal for creating inventory rotation with a first-in, first out dynamic.

- Concentrating processes into tighter spaces reduces walking/transport time, which allows pickers to focus on the job at hand in tight zones rather than walking carts.

- You can use a pick module to separate people from forklifts or other industrial vehicles. This is one of the most important safety factors in any warehouse.

- Pick module takeaway conveyors can enforce consistent product flow from pickers to packers to the shipping docks. This is more even and reliable than manual transport methods. Don’t forget the efficiency that’s inherent from gaining control of this pace.

- Pick modules are scalable for new inventory or business demands. In some cases, you can design them for future expansion by adding levels if you have the vertical space, or extending the platforms to create more horizontal work space.

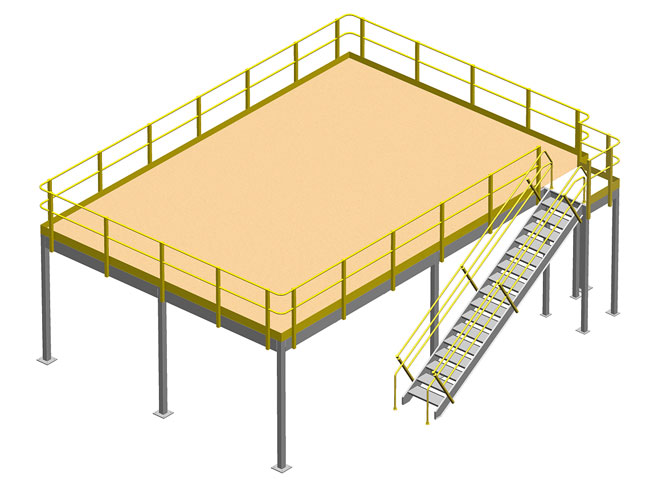

Technically, a simple mezzanine can be called a pick module, but usually it’s a combination of picking and replenishment methods that involve some of the following elements:

Mezzanine structure: what type of platform?

Mezzanines can be supported by structural posts, shelves or racks. Although any of these methods work, many pick modules opt for rack support because they’re storing pallets or inserting carton flow into the structure. If the mezzanine is structural, you can still utilize any of these elements, but will need to install it atop the decking rather than support it directly with the structure.

Mezzanine type |

Pick module factors |

|

Structural mezzaninesStructural mezzanines provide flexible space because they’re supported by fewer and smaller columns–you can position sprinkler systems, landings and stairways more efficiently. However, you might need to pour footings depending on the situation. Additional support for point loads (racks, shelves, etc.) could be needed. Vertical clearance is sometimes less than with rack or shelf systems. |

|

Rack-supported mezzaninesStorage options on a rack-supported system range from carton flow to pallet flow to static pallet storage to cantilever. It’s economical compared to structural platforms; you usually won’t need footings. Column quantity, placement and space footprint can be more limited. Vertical and cross-aisle expansion requires forethought and planning. |

|

Shelf-supported mezzaninesShelving systems can support most pick module designs, and are ideal for piece-picking operations. Bin storage applications are extremely space-efficient, which is why you see them in parts departments. Shelving can hold heavy weights for applications like records storage. Because it’s very focused on density, a shelf-supported mezzanine is less versatile. |

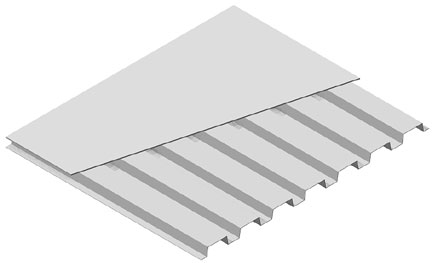

Floor/decking options

Decking type depends on your application, floor needs and mezzanine type. Many pick modules require a smooth floor that allows wheeled carts and pallet jacks to operate for picking or replenishment, so it’s important to understand the total product flow scheme when the pick module is planned.

- Bar grating is a popular option for mezzanines that do not use wheeled transport on their levels. Its open design allows light and air circulation between levels. Fire suppression systems can work between bar grate levels.

- Resin deck and plywood let you push carts on the pick module’s elevated levels. It’s more comfortable to stand, work and walk on, but will require lighting, circulation and fire control on each level of the pick module. It prevents smaller items from falling through gratings toward lower levels.

- Steel decking obstructs vision and allows carts or pallet jacks. Use steel when activity on the level might abuse a wood or resin floor.

See mezzanine decking options for more details.

Specialty decking: the considerations

Specialty decking such as fiberglass or plastics for chemical or washdown applications can also be specified. Remember that no matter your decking style, you will need to mount stairs, landings and handrails on your pick module. These often integrate with various systems, but must be considered in advance for successful implementations.

Carton & gravity flow for split and full case picking operations

Carton flow can be added to any pick module level. Because it’s so versatile, it lets you execute either full case or piece picking, depending on the SKU and picking needs.

You can integrate it into the rack structure on a rack-supported system or erected on structural mezzanine platforms. Flow racks enforce inventory rotation by ensuring the freshest product is presented to order pickers at all time. It requires effort to replenish, as pallets must be placed on the module, then broken down and segmented into the infeed side of the flow racks.

Picking strategies

Picking from carton flow is simple, particularly a pick-to-light system or other technology is deployed. Flow storage works best when you have many SKUs served at a high volume. It allows you to rearrange pick faces quickly and efficiently, so it’s ideal for reslotting efforts for operations that see frequent changes in product preferences or seasonal variations.

Read more: First-In, First-Out Storage Considerations

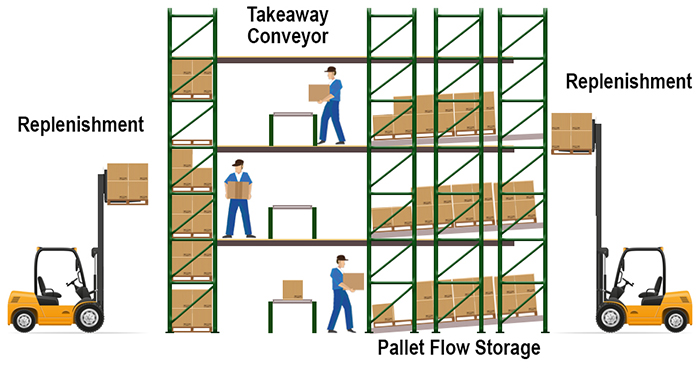

Pallet flow systems and flow racks for full case and pallet building applications

Like carton flow, pallet flow systems enforce first-in, first-out rotation. These systems are also used for replenishment, allowing a deeper storage aisle at any mezzanine level. The concept tends to be utilized for picking full cases rather than partials. Replenishment is relatively simple, with pallet flow lanes ranging from a couple of pallets to 5-plus pallets deep. Although the illustration above depicts takeaway conveyors, you can execute that with pallet conveying systems, pallet jacks or carts.

One key to remember is that pallet flow leaves an unguarded edge, which should be protected from fall risks (see below).

Read more: The Process of Specifying Pallet Flow Rollers & Wheels

Storage racks and shelving

These elements are typically built into rack and shelf supported pick modules, but can be added to platform-based installations. They are used for various applications, and in mixed usage for slow movers or bulk products.

- Shelving is best used for dense parts storage. You’ll see this type of storage in parts departments or SKU-intensive picking ecommerce or retail picking operations. Shelving may not be adequate for higher-volume or mixed pick situations, but has its role in most every pick module. You can use it for slow movers, bulk storage or reserve inventory, even in picking operations where you have automated takeaway systems.

- Rack storage is integrated into many pick modules simply because so many depend on rack structure as their support system. It can be used for picking cases, but typically not pieces. It’s also used for bulk storage.

Takeaway conveyor systems

A pick module becomes truly automated when conveyor or other dynamic elements are integrated.

Conveyors are frequently incorporated into pick modules, and can work with most any picking strategy. In order picking operations, conveyors are installed between aisles so that workers can pick their portion of an order. This can be done for full cases or piece-picks, into totes or into cartons. The conveyor moves orders to the next picking zone until it’s eventually completed and sent to downstream processes like sortation or packing. Using conveyors instead of cart-based picking is less labor-intensive, and is the key to reducing transit times and needless walking.

Read more: Educational Development Corporation’s E-commerce Order Fulfillment Center Meets Viral Demand

Vertical transport systems

Most pick modules require product transport up to and down from various platform levels. There are many options for this task, each with its strengths and weaknesses.

Transport type |

Factors for vertical transport |

|

Spiral conveyors and chutesSpiral conveyors are the throughput champion for vertical movement and are frequently the method of choice for pick module applications where pick and pass orders travel through multiple zones. They occupy less space than alternatives like inclined conveyors, but their chief advantage is their throughput. They are an excellent buffer zone, allowing you to concentrate (depending on loads and heights) a large quantity of product in a tight space to queue for packing or machine integrations. |

|

Vertical reciprocating conveyors and continuous lift systemsVertical conveyors and other vertical lifts are an ideal way to replenish and take away pallets (and sometimes packages) from a pick module. These lifts are space-efficient, with footprints as small as 36″ x 36″, so they can be added to the side of a multilevel module to service any number of levels. Even if your pick module is executing piece or small carton picking, you can use a VRC for pallet transport in replenishment operations. Automated package/pallet lifts are an alternative to VRCs. |

|

Incline conveyorsIncline conveyors are more economical than spiral systems and can function efficiently for a variety of integrations. They tend to serve single- or lower-level pick modules, but can also be integrated into multi-level applications if the operation calls for it. When space isn’t a critical factor and the pick module design allows, they are a strong alternative to buffer and move totes or cartons between levels. Various belt styles allow for a number of integrations (into carousels, with other conveyors or other machinery). |

|

Forklift loading and unloadingBecause floor space isn’t occupied by a conveyor or lift, forklift access doesn’t permanently require extra space. If you have a forklift, this method has no hard costs beyond a gate system for pallet egress. Forklift access is slow, less safe due to open ledges and labor intensive. Your forklift must be able to reach every level of your pick module, assuming you need to access every level. For certain tasks and low-throughput needs, forklift access is convenient and usable. |

Read more: Vertical Pallet Movement Options

Pick module safety factors

Forklift-pedestrian separation

Pick modules are safer than the same number of mixed picking areas on a warehouse floor because they naturally separate forklifts and pedestrians. By controlling the egress points to your pick module, you can ensure that the people who work on or around it are separated from forklift aisles the majority of the time.

Rack loads and capacities

Be sure that any storage equipment used on the pick module is loaded correctly and within capacity tolerance. Post rack capacities on rack structure and train replenishment teams on proper placement and weight tolerances.

Pick module fall protection

Personnel fall protection: Guarding ledges against people falling should be evaluated at any place where people can come into contact with a ledge.

- Run of the platform guards: Installing railing to applicable industry standards for all open ledges is mandatory. You should understand handrails and various safety standards. The basic issues are: (1) rail height, (2) rail capacity and (3) number of horizontal mid-rails. If you’re operating in a seismic zone, there are specific regulations when it comes to “run of the mezzanine” rails and the number of mid-rails. Your safety evaluation should also include stair and landing platform handrails for grip and strength.

- Loading access fall prevention: Mezzanine access points–such as when a mezzanine is replenished–are a particular point of concern. By nature, these access points create open ledges, but you have options to guard those ledges with specific types of gates and processes.

- Trip and fall accidents: Your mezzanine decking should be smooth, without borders or edges that could snag or trip people.

Above: This pick module uses clear barriers to help reduce falling item issues. Kickplates are also installed at platform level; additional barriers will not tend to reduce kickplate requirements.

Product/item fall protection

Any elevated platform should have kickplates, guards, nets and other methods to help prevent dropped items from hitting people or machinery below. Kickplates rise vertically from mezzanine edges, usually attached to handrails to prevent (for instance) small items from dropping on people below. You can also deploy safety nets, mesh or solid guarding to fully guard the entire handrail.

Download our Mezzanine & Pick Module Guide

The space you already have is more valuable than the space you could acquire. Adding a mezzanine to your facility can rapidly increase your vertical space available, and provide added efficiency and long-term value to your operations. Check out our guide for mezzanine specifications, styles, accessories and applications. You will find quick, useful information on mezzanines and how you can use them more effectively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.