Live Roller Spool Conveyor - 18"W x 40'L, 1.9" Rollers

General transport conveyor with the capabilities of accumulating products with back-pressure

SKU: 40.30.18.40

Manufacturer: Hytrol

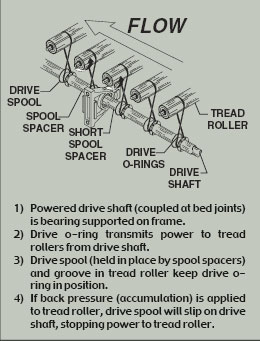

How live roller conveyor works:

- Powered drive shaft (coupled at bed joints) is bearing supported on the frame.

- Drive o-ring transmits power to the tread rollers from the drive shaft.

- Drive spool (held in place by spool spacers) and groove-in tread roller keep the drive o-ring in position.

- If back pressure (accumulation) is applied to the tread roller, the drive spool will slip on the drive shaft, stopping power to tread roller.

Width

Belt conveyor width is measured in two ways; overall width (or bed width) and belt width. Overall width includes the width of the frame, which is 1-1/2" on either side of the belt. This means that the belt width would be 3" less than the overall width of the conveyor. Keep this in mind when determining what width of conveyor you need to meet your package requirements.

Shipping

Conveyor is crated and shipped in 5ft and 10ft sections, depending on the overall length of the conveyor, and will need to be bolted together on-site. The drive assembly, reducer, and motor will shipped attached to one of these sections. Because these sections are unattached for shipping, the conveyor belt itself will also have to be attached onsite.

Please note that this conveyor DOES NOT include electrical components or switches.

- Lead Time: 2 weeks + transit time

- Width: 18"

- Length: 40'

- Color: Hytrol Green

- Overall Width: 18"

- Between Rails: 15"

- Overall Length: 40'

- Section Type: Straight

- Width Between Rails: 15"

- Model: 190-NSP

- Type: Accumulation

- Pressure: Minimum (2%)

- # of Supports: 5

- Rollers: 1.9" diameter galvanized tube

- Speed: 65 feet per minute

- Drive: Mounted underneath, placed near center of conveyor

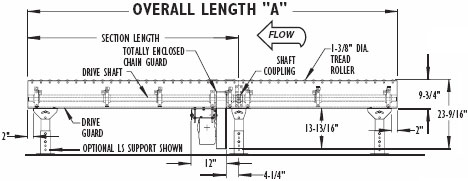

- Bed: Roller bed mounted in 9-1/2" x 12 ga. steel channel frame bolted together with splice plates

- Drive Shaft: 1" dia. steel shaft. Chain coupling at bed joints. Located on left hand side.

- Speed Reduction: Sealed worm gear C-Face speed reducer. Number 50 roller chain to drive shaft

- Drive Spools: 2" dia. Delrin spool held in place on drive shaft with spool spacers

- Drive Guard: Underside of drive shaft with spools and drive o-rings guarded full length of conveyor

- Drive O-Rings: 3/16" dia. polyurethane o-ring from drive spool to tread rollers

- Roller Spacing: 3" top roller spacing; 6" spacing for underside pressure rollers

- Bearings: Sealed, pre-lubricated, self-aligning, ball bearings with eccentric lock collar on drive shaft. Pre-lubricated ball bearings in tread rollers

- Cross Bracing: Rods with turnbuckles are fastened to underside of bed to provide alignment and insure product tracking

- Capacity: Maximum load per powered roller 15 lbs. NOTE: Maximum load capacity will be less for products with soft or irregular bottoms. Total load NOT TO EXCEED capacity in chart.

- Weight: 1467.4 lbs. ea.

Drawings & Capacity

* Limited to 15 lbs. per driven roller

- Specification Sheet - 190-NSP - (730 KB PDF, opens in new window)

- Installation and Maintenance Manual(4.12MB PDF, opens in new window)