Warehousing Insights | Material Handling Systems Topics from our Blog

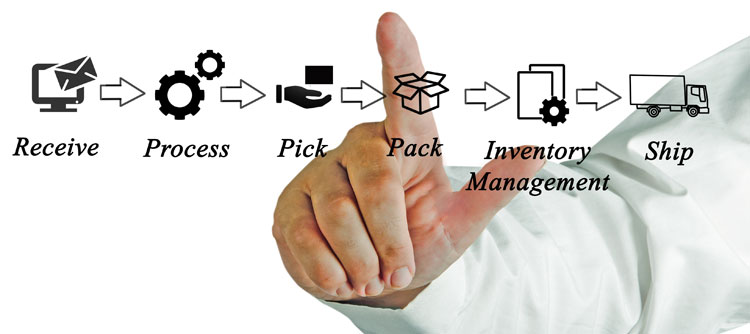

- Packing Packs a Punch

- Options for Pick Modules and Empty Carton Transport

- Order Picking, Accuracy and ROI for Industrial Automation

- Shoptalk: EDC Pick Module Expansion

- How to Handle and Remove Corrugated Box Waste in Distribution Applications

- Ways to Pick Full Cases Faster, More Accurately and More Ergonomically

- Download Our Guide To Order Picking

- How to Make Packing More Efficient

- Putaway is Critical for Distribution Success

- Download Our Guide To Carton Flow