1.9" Galvanized Roller Curve - 90 deg., 30" OAW

Non-powered, gravity conveyor moves product quickly and with very little maintenance

SKU: 19GSRC-27-90D

Manufacturer: Hytrol

- Frame: Steel

- Between Rail Width: 27"

- Rollers: 1.9", 16 gauge galvanized steel

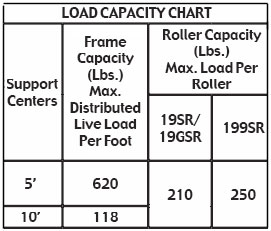

- Roller Centers: -

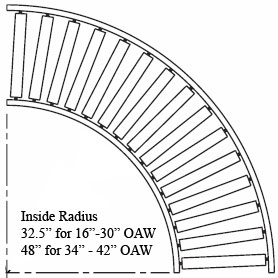

- Type: 90° curve, medium duty

- Frame Construction: 10 gauge powder painted steel with bolt-in cross members

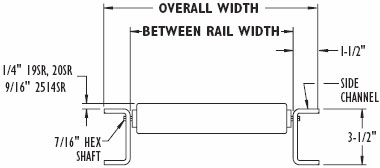

- Channel: 3-1/2" with 1-1/2" flange

- Roller Bearings: Labyrinth sealed (dust & debris protection) and grease packed

- Axles: 7/16" hex shaft, spring loaded for easy replacing

- Couplings: Square butt couplings on both ends

- Weight: 177.0 lbs. ea.

Connecting Conveyor

Each section of conveyor has butt couplings on both ends. These ends can be bolted together between conveyor sections to create long conveyor lines. Joined sections must have support installed beneath the couplings.

Example: If you are joining a 10 foot section and a 90 degree curve section, the minimum number of supports you would need is 3 supports plus 1 single center leg support; one support under the far end of each section, one support beneath the connection, and the center leg support for the outside edge of the curve. This configuration however would give your 10 foot section a lower capacity than the curved section unless you placed an intermediate support under the 10 foot.

Width

Conveyor width is measured in two ways; overall width (OAW) and between rail width. Overall width includes the width of the frame, which is 1.5" on either side of the rails. This means that the between rail width would be 3" less than the overall width of the conveyor. Keep this in mind when determining what width of conveyor you need to meet your package requirements.