Conveyor Terminology Glossary

Browse conveyor information alphabetically

Request InfoThis is a basic guide to conveyor terminology, designed to help resolve differences in terminology or jargon. If you have any questions, please contact us for assistance.

A-B

ACCUMULATING CONVEYOR (Or, accumulation conveyor): Any conveyor designed to allow collection (accumulation) of material. May be roller, live roller, belt and gravity conveyors.

ALLIGATOR LACING: Lacing attached to the belt with a hammer for the purposes of joining the ends of the belt together to form a continuous loop.

AXLE: A non-rotating shaft on which wheels or rollers are mounted.

BAG FLATTENER: A mounting assembly used to hold one conveyor upside down over another conveyor in order to squeeze or flatten the product.

BALL TABLE: A group of ball transfers over which flat surface objects may be moved in any direction.

BALL TRANSFER: A device in which a larger ball is mounted and retained on a hemispherical face of small balls.

BARE PULLEY: A pulley which does not have the surface of its face covered (or lagged).

BEARING: A machine part in or on which a shaft, axle, pin or other part rotates.

BED: That part of a conveyor upon which the load rests or slides while being conveyed.

BED LENGTH: Length of bed sections only required to make up conveyor excluding pulleys, etc., that may be assembled at ends.

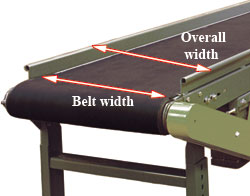

BED WIDTH: Refers to the overall width of the bed section.

BELT: A flexible band placed around two or more pulleys for the purpose of transmitting motion, power or materials from one point to another.

BELT SCRAPER: A blade or brush caused to bear against the moving conveyor belt for the purpose of removing material sticking to the conveyor belt.

BELT SPEED: The length of belt, which passes a fixed point within a given time. It is usually expressed in terms of "feet per minute".

BETWEEN RAIL WIDTH: (BR) referred to as the distance between the conveyor frame rails on a roller bed, live roller or gravity type conveyor. Also referred to as (BF) Between Frame.

BOOSTER CONVEYOR: Any type of powered conveyor used to regain elevation lost in gravity roller or wheel conveyor lines.

BRAKE MOTOR: A device usually mounted on a motor shaft between motor and reducer with means to engage automatically when the electric current is cut off or fails.

BRAKE ROLLERS: Air or mechanically operated brakes used underneath roller conveyor to slow down or stop packages being conveyed.

BUTT COUPLING: Angles or plates designed to join conveyor sections together.

C

CASTERS: Wheels mounted in a fork (either rigid or swivel) used to support and make conveyors portable. See our caster section for information on industrial applications.

CEILING HANGERS: Lengths of steel rod, attached to the ceiling, from which conveyors may be supported to provide maximum utilization of floor space or when required height exceeds floor support capability.

CENTER DRIVE: A drive assembly mounted underneath normally near the center of the conveyor, but may be placed anywhere in the conveyor length. Normally used in reversing or incline application.

CHAIN: A series of links pivotally joined together to form a medium for conveying or transmitting motion or power.

CHAIN CONVEYOR: Any type of conveyor in which one or more chains act as the conveying element.

CHAIN DRIVE: A power transmission device employing a drive chain and sprockets.

CHAIN GUARD: A covering or protection for drive or conveyor chains for safety purposes.

CHAIN ROLLER CONVEYOR: A conveyor in which the tread rollers have attached sprockets which are driven by a chain.

CHUTE: A trough through which objects are lowered by gravity. Can either be a slider bed or roller/wheel bed.

CLEAT: An attachment fastened to the conveying surface to act as a pusher, support, check or trip, etc. to help propel material, parts or packages along the normal path of conveyor travel.

CLEATED BELT: A belt having raised sections spaced uniformly to stabilize flow of material on belts operating on inclines. Cleats may be a part of the belt or fastened on.

CLIPPER LACING: Lacing attached to the belt with a clipper lacing machine.

CLUTCH DRIVE: Drive used to disengage motor from reducer without stopping the motor or cutting the power.

CLUTCH-BRAKE DRIVE: Drive used to disengage motor from reducer and stop conveyor immediately without stopping the motor or cutting the power.

CONSTANT SPEED DRIVE: A drive with no provisions for variable speed or a drive with the characteristics necessary to maintain a constant speed.

CONVERGING: A section of roller or wheel conveyor where two conveyors meet and merge into one conveyor.

CONVEYING SURFACE: Normal working surface of the conveyor.

CROSS BRACING: Rods and turnbuckles placed diagonally across roller bed or live roller type conveyors to aid in squaring frames, necessary for tracking purposes.

CROSSOVER: A short section of conveyor placed in a conveyor when drive is switched to opposite side of conveyor. (Not the same as a conveyor crossover structures, which spans floor conveyor so that personnel can cross).

CROWNED PULLEY: A pulley which tapers equally from both ends toward the center, the diameter being the greatest at the center.

CURVE CONVEYOR: Any skatewheel, roller, or belt conveyor which is produced with a degree of bend so as to convey products away from the straight flow.

D-E

DECLINE CONVEYOR: A conveyor transporting down a slope.

DEGREE OF INCLINE: Angle of slope (in degrees that a conveyor is installed).

DIFFERENTIAL CURVE: A curved section of roller conveyor having a conveying surface of two or more concentric rows of rollers. Also referred to as a Split Roller Design.

DISCHARGE END: Location at which objects are removed from the conveyor.

DIVERGING: A section of roller or wheel conveying which makes a connection for diverting articles from a main line to a branch.

DRIVE: An assembly of the necessary structural, mechanical and electrical parts which provide the motive power for a conveyor. Usually consisting of motor/reducer, chain, sprockets, guards, mounting base and hardware.

DRIVE PULLEY: A pulley mounted on the drive shaft that transmits power to the belt with which it is in contact. Pulley is normally positive crowned and lagged.

DUTCHMAN: A short section of belt, provided with lacing, in a conveyor belt which can be removed when take-up provision has been exceeded.

EMERGENCY PULL CORD: Vinyl coated cord that runs along the side of the conveyor that can be pulled at any time to stop the conveyor. Used with an Emergency Stop Switch.

EMERGENCY STOP SWITCH: Electrical device used to stop the conveyor in an emergency. Used with an Emergency Pull Cord.

EXTENDABLE CONVEYOR: Roller or wheel conveyor that may be lengthened or shortened within limits to suit operating needs. Standard extended lengths are 20 ft., 30 ft., and 40 ft.

EZLogic: Electronic Zero Pressure Logic for zero pressure accumulation conveyor systems.

F-H

FEEDER: A conveyor adapted to control the rate of delivery of packages or objects.

FLAPPER GATE: A hinged or pivoted plate used for selectively directing material handled.

FLAT FACE PULLEY: A pulley on which the face is a straight cylindrical drum, i.e. uncrowned.

FLOOR SUPPORTS: Supporting members with vertical adjustments for leveling the conveyor.

FLOW: The direction of travel of the product on the conveyor.

FPM: Feet per minute, typically in regard to the speed of a conveyor line.

FRAME: The structure which supports the machinery components of a conveyor.

FRAME SPACER: Cross members to maintain frame rail spacing. Also referred to as Bed Spacer.

GATE: A section of conveyor equipped with a hinge mechanism to provide an opening for a walkway, etc. (Manual or Spring Loaded)

GRAVITY BRACKET: Brackets designed to permit gravity conveyors to be attached to the ends of a powered conveyor.

GRAVITY CONVEYOR: Roller or wheel conveyor over which objects are advanced manually by gravity.

GUARD RAIL: Members paralleling the path of a conveyor and limiting the objects or carriers to movement in a defined path.

HOG RINGS: Rings used to hold the shaft in a roller.

HORIZONTAL FLOOR SPACE: Floor space required for a conveyor.

HORSEPOWER: (HP) A measure of the time rate of doing work defined as the equivalent of raising 33,000 pounds one foot in one minute. Electrically, one horsepower is 746 watts.

HZ: HERTZ - Electrical terminology, a unit of frequency equal to one cycle per second. Most common cycle time is 60 Hertz.

I-L

INCLINE CONVEYOR LENGTH: Determined by the elevation change from infeed to discharge versus the degree of incline.

INCLINE CONVEYOR LENGTH: Determined by the elevation change from infeed to discharge versus the degree of incline.

INCLINED CONVEYOR: A conveyor transporting up a slope (to a mezzanine, second level storage area, an overhead line, or other elevated surface). Also called an extendible or flexing conveyor.

INFEED END: The end of a conveyor nearest the loading point.

INTERMEDIATE BED: A middle section of conveyor not containing the drive or tail assemblies.

INTERPOLATE: To compute intermediate values.

KNEE BRACES: A structural brace at an angular position to another structural component for the purpose of providing vertical support.

KNURL THUMB ADJUSTABLE NUT: A nut used on accumulating conveyors to adjust the pressure required to drive the product, may be turned with- out the use of tools.

LACING: Means used to attach the ends of a belt segment together.

LAGGED PULLEY: A pulley having the surface of its face crowned with a material to provide for greater friction with the belt.

LIMIT SWITCH: Electrical device used to sense product location.

LIVE ROLLER CONVEYOR: A series of rollers over which objects are moved by the application of power to all or some of the rollers. The power transmitting medium is usually belting or chain.

M-O

MACHINE CROWNED PULLEY: A pulley in which the crown or vertex has been produced by an automatic, usually computer driven, machine.

MAGNETIC STARTER: An electrical device which controls the motor and also provides overload protection to the motor.

MANUAL START SWITCH: A simple one direction switch used to turn the conveyor on or off.

MINIMUM PRESSURE ACCUMULATING CONVEYOR: A type of conveyor designed to minimize build-up of pressure between adjacent packages or cartons. (138-ACC - 190-ACC)

MOTOR: A machine which transforms electric energy into mechanical energy. Standard motors are dual voltage and operate at 1725 RPM.

NEGATIVE CROWNED PULLEY: A pulley with raised areas set equally in from each end. This crown is used on tail pulleys 24 in. OAW and wider and aids in belt tracking.

NET LIFT: The net vertical distance through which material is moved against gravity by a conveyor.

NIP POINT GUARD: A guard placed to eliminate points or areas on the conveyor where injuries might occur.

NOSE ROLLER: A small roller, used on power belt curve conveyors, to reduce the gap at the transfer points.

NOSEOVER: A section of conveyor with transition rollers placed in conveyor to provide transition from incline to horizontal or horizontal to incline.

O-RING: Polyurethane bands polyurethane used to transmit drive power from roller to roller or spool to roller. (138-SP, 190-SP, 2514-SP)

OVERALL LENGTH: (OAL) The dimension outside of pulley to outside of pulley including belting or lagging, of any conveyor lengthwise.

OVERALL WIDTH: (OAW) The dimension outside to outside of frame rails.

OVERHEAD DRIVE: A drive assembly mounted over a conveyor which allows clearance for the product.

P

PACKAGE STOP: Any of various devices, either manual or mechanical, used to stop flow on a conveyor

PARTS CONVEYOR: A conveyor used to catch and transport small parts, Stampings, or scrap away from production machinery to hoppers, drums, or other operations. (PC, PCA, PCL, PCX, PCH)

PHOTO CELL: Electrical device used to sense product location.

PIVOT PLATE: The gusset which attaches the conveyor to the support leg.

PLASTISOL COATING: Poly-vinyl chloride (PVC) covering for roller tubes to prevent product damage or marking. Usually (#70 durometer) green or (#90 durometer) red in color.

PLOW: A device positioned across the path of a conveyor at the correct angle to discharge or deflect objects.

POLY-TIER SUPPORT: Supporting members capable of supporting more than one level of conveyor at a time. Each tier has vertical adjustment for leveling the conveyor.

POP-OUT ROLLER: A roller, normally placed on the ends of a belt conveyor, used to aid in transfer, and set in a wide groove to allow it to eject if an object comes between it and the belt.

PORTABLE CONVEYOR: Any type of transportable conveyor, usually having supports which provide mobility.

PORTABLE SUPPORT: Supporting members which provides conveyor mobility by use of casters or wheels.

POSITIVE CROWNED PULLEY: A pulley which tapers equally from both ends toward the center, the diameter being the greatest at the center. The crown aids in belt tracking.

POWER BELT CURVE: A curve conveyor which utilizes a belt, driven by tapered pulleys.

POWER CONVEYOR: Any type of conveyor which requires power to move its load. See Power Roller Conveyors, Power Belt, Power Flexible - and many other types.

POWERED FEEDER: A driven length of belt conveyor, normally used to move product horizontally onto an incline conveyor.

PRESSURE ROLLER: A roller used for holding the driving belt in contact with the load carrying rollers in a belt driven live roller conveyor.

PRODUCT FOOTPRINT: The surface of the product that comes in contact with the belt, rollers, or wheels of the conveyor.

PULLEY: A wheel, usually cylindrical, but polygonal in cross section with its center bored for mounting on a shaft.

PUSH BUTTON STATION: An electrical device which operates a magnetic starter.

PUSHER: A device, normally air powered, for diverting product 90 degrees from one conveyor line to another line, chute, etc.

R

RETURN IDLER: A roller which supports the return run of the belt.

REVERSIBLE: A conveyor which is designed to move product in either direction.

ROLLER: A round part free to revolve about its outer surface. The face may be straight, tapered or crowned. Rollers may also serve as the rolling support for the load being conveyed.

ROLLER BED: A series of rollers used to support a conveying medium.

ROLLER CENTERS: The distance measured along the carrying run of a conveyor from the center of one roller to the center of the next roller.

ROLLER CONVEYOR: A series of rollers supported in a frame over which objects are advanced manually, by gravity or by power. Links: see Gravity Roller Conveyor or Power Roller Conveyor.

S

SET HIGH: Vertical spacing which allows the rollers to be mounted above the frame rails.

SET LOW: Vertical spacing which allows the roller to be mounted below the top of the frame rails.

SHAFT: A bar usually of steel, to support rotating parts or to transmit power.

SHEAVE: A grooved pulley wheel for carrying a v-belt.

SIDE CHANNELS: Members which support the rollers on the side of the conveyor.

SIDE MOUNTED DRIVE: A drive assembly mounted to the side of the conveyor, normally used when minimum elevations are required.

SIDE TABLES: Steel tables attached to either side of conveyor bed to provide working surface close to conveyor.

SINGULATION MODE: Mode where packages are- automatically separated while traveling down the conveyor.

SKATEWHEEL CONVEYOR: A type of wheel conveyor making use of series of skatewheels mounted on common shafts or axles, or mounted on parallel spaced bars on individual axles.

SLAT CONVEYOR: A conveyor which uses steel or wooden slats mounted on roller chain to transport the product.

SLAVE DRIVE: A conveyor drive powered from another conveyor instead of having its own prime power source.

SLIDER BED: A stationary surface on which the carrying run of a belt conveyor slides, such is in Model TA Belt Conveyors.

SLUG MODE: Allows all packages to be released simultaneously.

SNUB IDLER: Any rollers used to increase the arc of contact between a belt and drive pulley.

SORTATION CONVEYOR: A conveyor which is able to sort different packages or products to specific take-away lines. (SC, QS-1, QS-2). Link: see Sortation Conveyors.

SPEED REDUCER: A power transmission mechanism designed to provide a speed for the driven equipment less than that of the prime mover. They are generally totally enclosed to retain lubricant and prevent the entry of foreign material.

SPOOL CONVEYOR: A conveyor where power to the rollers is accomplished by o-rings driven by spools on a rotating shaft. (138-SP, 190-SP, 2514-SP)

SPUR: A conveyor section to switch unit loads to and from the mainline.

SUPPORT: Arrangement of members used to maintain the elevation or alignment of the conveyors. Supports can take the form of hangers, floor supports, or brackets and can be either stationary or portable.

SWITCH: (1) Any device for connecting two or more contiguous package conveyor lines; (2) An electrical control device.

T

TAIL END: Usually the end of a conveyor nearest loading point.

TAIL PULLEY: A pulley mounted at the tail end of a conveyor, its purpose is to return the belt.

TAKE-UP: The assembly of the necessary structural and mechanical parts which provide the means to adjust the length of belt and chain to compensate for stretch, shrinkage or wear and to maintain proper tension.

TANGENT: Straight portion after a curve conveyor.

TAPERED ROLLER: A conical conveyor roller for use in a curve with end and intermediate diameter proportional to their distance from center of curve.

TAPERED ROLLER CURVE: A curved section of roller conveyor having tapered rollers.

THROUGHPUT: The quantity or amount of product moved on a conveyor at a given time.

TOTAL LOAD: Amount of weight distributed over the entire length of a conveyor.

TRACKING: Steering the belt to hold or maintain a desired path.

TRAFFIC COP: A mechanical or electrical mechanism to prevent collision of objects as they merge from two conveyor lines into a single line.

TRANSFER: A device or series of devices, usual- ly mounted inside a conveyor section, which uses belts, chains, o-rings, rollers, or skate- wheels, to move products at right angles to adjacent or parallel conveyor lines.

TRASH CONVEYOR: A conveyor, normally a belt conveyor, equipped with high side guards, used in transporting empty cardboard boxes and paper trash away from working areas.

TREAD PLATES: Diamond top steel filler plates used to fill the gap between rollers on roller conveyor.

TRIPOD SUPPORT: Three legged stand for small roller and skatewheel conveyor. Usually easily moved or aligned to maintain elevation of the conveyor.

TROUGHED BED: A belt conveyor designed with a deep trough used for carrying broken glass, cans, wood chips, stampings, etc. Also used in recycling operations. (Model TR is a typical troughed bed conveyor.)

TROUGHING ATTACHMENTS: Angles used on belt conveyors to cup the edge of the belt.

TURNBUCKLE: A link with a screw thread at both ends, used for tightening the rod, normally used in cross-bracing.

TURNING WHEEL: Wheel mounted on an adjustable bracket to help insure proper package orientation.

TURNTABLE: A horizontal, rotatable conveyor mechanism used for transferring objects between conveyors which are in angular relation to one another. (90 degrees, 180 degrees, 360 degrees)

TWO-PULLEY HITCH: A special transition section for moving product from horizontal to incline.

U-Z

UNDERSIDE BED COVER: Sheet metal used to cover the underneath side of a conveyor.

UNDERSIDE TAKE-UP: A take-up section located beneath the bed of a belt conveyor.

UNDERTRUSSING: Members forming a rigid framework underneath the conveyor, used for supporting the conveyor.

VARIABLE SPEED: A drive or power transmission mechanism that includes a speed changing device.

- Standard mechanical variable speed ratios- 6:1

- A.C. electrical variable speed ratio-10:1

V-BELT: A belt with a trapezoidal cross section for operation in grooved sheaves permitting wedging contact between the belt sides and groove sides.

ZERO PRESSURE ACCUMULATING CONVEYOR: A type of conveyor designed to have zero build-up of pressure between adjacent packages or cartons.