Carousels & VLMs: Frequently-Asked Questions

Knowledge base for industrial & warehouse carousels

Ask our Experts!

Read more about order picking solutions and automation on our Warehousing Insights Blog

What is an industrial carousel?

Carousels and VLMs deliver stored items directly to operators at a fixed access opening, called the access window. Shelving or carriers rotate vertically or horizontally, reducing walking time, improving picking efficiency, and increasing storage density compared to static shelving.

The Hänel x Cisco-Eagle partnership focuses on vertical storage systems, including the Rotomat vertical carousel and Lean-Lift Vertical Lift Modules from start to finish, with comprehensive design, integration, installation and maintenance services.

Hänel vertical storage systems

What is a Hänel Rotomat® carousel?

The Hänel Rotomat is a vertical carousel storage system that uses rotating carriers to deliver stored items to an operator. It optimizes vertical space, provides ergonomic access, and supports organized, controlled storage and retrieval.

What is a Lean-Lift® VLM?

Vertical lift modules (VLMs) store items on trays within a steel enclosure. They automatically deliver the requested tray to pickers at an ergonomic access window. VLMs use an extractor to retrieve trays from fixed storage locations, helping optimize vertical space, improve picking efficiency, and organize inventory in a compact footprint. This typically makes them faster than carousels.

How are vertical carousels and VLMs different?

- VLMs store items on trays in fixed locations and use an internal extractor to retrieve and deliver trays to the access opening.

- A vertical carousel stores items on rotating carriers that move in a continuous vertical loop to present inventory to the operator.

- Carousels rotate the entire inventory. VLMs move only the needed tray.

Video: the differences between VLMs and vertical carousels

| Feature | Vertical Lift Module (VLM) | Vertical Carousel |

|---|---|---|

| Storage method | Trays stored in fixed vertical locations | Carriers rotate in a continuous vertical loop |

| Retrieval method | Internal extractor retrieves and delivers trays to the access point | Entire carrier loop rotates to present items |

| Item access | A single tray delivered to the access opening. Faster access than carousels | Carrier rotates all trays; because the entire inventory rotates, can be slower than VLMs |

| Space utilization | Optimizes vertical space with variable tray spacing | Uses vertical space with fixed carrier spacing |

| Size and modularity | VLMs allow taller units with stacking modules | Carousels are a single fixed height |

| Best suited for | High-density storage with varying item heights | Fast access to frequently picked items |

| Goods-to-person | Yes | Yes |

| Typical applications | Parts storage, inventory control, organized tray-based storage | Order picking, parts access, frequently retrieved items |

| Example Hänel system | Hänel Lean-Lift VLMs | Hänel Rotomat vertical carousels |

What colors and finishes are available for Hänel systems?

Carousels and VLMs feature a range of standard colors, typically a dual-tone front/side finish with Pearl Grey and another color. Customized colors and corporate branding can be added to any VLM or carousel to fit your needs.

- Pearl Grey/Grey - standard

- Pearl Grey/Green - standard

- Pearl Grey/Blue - standard

- Pearl Grey/Bordeaux - standard

- Silver/Anthracite - premium

- Customized and corporate finishes available

What safety systems are included with Hänel carousels and VLMs?

Many safety features are inherent in carousels and VLMs, and many others are built into Hänel systems. Safety functionality is integrated into system design and controls to support safe operation during storage and retrieval cycles.

- Read more: VLM safety features

- Read more: Vertical carousel safety features

How are these systems certified? Do they comply with safety guidelines and regulations?

Hänel Rotomat® carousels have the German GS mark and the Swiss SUVA inspection certificate attesting to their safety[SS4.1][SS4.2]. They are compliant with OSHA and ANSI machine safety guidelines and are engineered with CE-compliant control systems.

Hänel solutions meet or exceed virtually all U.S. safety standards and compliance systems. They can be equipped with fire-resistant enclosure panels. You can integrate sprinkler systems other fire extinguishers into carousels and VLMs.

How do carousels and VLMs affect ergonomics?

Carousels and VLMs are inherently safer due to baked-in ergonomics that deliver products to golden-zone heights that reduce bending, stretching, strains and awkward motions that endanger workers and cause musculoskeletal damage.

Read more: Improve Productivity with Ergonomic Storage System Design

Video: carousel ergonomics

What other safety factors or systems do carousels affect?

Exposure to machinery and moving parts: Chains, drives and other moving parts are safely contained within the carousel's enclosed steel case, so workers cannot inadvertently interact with moving components. Automatic tray stop prevents motion when access door is open, or other unsafe conditions are detected. This protects employees from reaching into the system when it is in motion.

Hänel safety threshold switches and light-barrier curtains are compliant with DIN EN 15095. Photoelectric light barriers monitor the access point, stopping the lift immediately during pick or put operations if a person or object enters the retrieval area. Emergency stop switches are positioned at user interfaces and service areas for immediate system shutdown

Lean-Lifts can be outfitted with second safety circuits that add redundancy to your carousel. The Hänel ESB (Expanded Safety Bypass) package lets you continue to safely operate in case of a malfunction. This allows safe, reliable operation until service can be performed.

Operational stability: Load warning imbalance devices for payloads over 3 tons help reduce loading issues and potential injuries. Stable carrier suspension with 4-point sliding carriage principle reduces instability and creates a safer operating environment.

Carousel applications and use cases

When should you consider a vertical carousel or VLM?

A combination of factors tend to combine to the use case for these systems. Space issues and travel times are often the primary drivers, but there are many other reasons to deploy carousel systems.

VLMs and carousels are often deployed when floor space is limited, inventory is spread across multiple shelving locations, or operators spend significant time walking to pick items. Other factors can include throughput issues, security problems and overall operational traceability for critical parts, inventory or tools.

- Shoptalk: Will a Carousel Work for You?

- Questions to Ask: Carousel Picking Systems

- Storage Efficiency: Shelves vs. Modular Drawers vs. Flow vs. Vertical Carousels

- Goods-to-Picker Methods and Alternatives

What types of items can I store in a vertical carousel or VLM?

You can store almost anything in a carousel or VLM system. Some larger unit loads may not be compatible with standard systems. We recommend consulting a storage professional to determine load compatibility in those cases.

Vertical carousels and VLMs can store a wide range of items, including parts, components, tools, maintenance supplies, and packaged goods. Suitable item size and weight depend on tray or carrier configuration and system capacity as defined in manufacturer technical data.

A good rule of thumb: if you can store it in shelves or cabinets or racking, you can store it in a VLM or carousel

What are the expected picking speeds from VLMs and industrial carousels?

Picking performance depends on system configuration, order profile, item size, and workflow. Speeds vary depending on order profile, item size, batching strategy, and system configuration. Because both VLMs and vertical carousels use a goods-to-person approach, they reduce walking time and search time compared to static shelving, racks or modular cabinets. Throughput is highly application-specific, and is affected by many factors.

- SKU count

- Item size and weight

- Integration level (Pick-o-Light, WMS batching, etc.)

- Operator training and capacity

- Sequencing and batching significantly influence throughput

General industry performances (without considering various options, loads or operational factors) break out to these ranges:

VLMs: 60 to 120 picks per hour for basic functions (single-order picks in basic configurations. For more optimized configurations (using pick-to-light, WMS integrations) the rates can be higher, at 120-150 picks per hour. Very high efficiency configurations can reach 300 lines per hour. Tray delivery speed, order batching strategy, tray storage density, operator pefrormance and software optimization impact VLM speeds.

Vertical carousels: typically perform at 80-150 picks per hour. Optimized configurations can reach 300 lines per hour. Carousels in pod layouts can be even faster, since one unit can rotate while another is being picked to reduce operator wait times.

Many factors affect these numbers, which are not specific to Hanel units.

How much can I store in a carousel or VLM?

Quick answer: quite a lot.

The number of SKUs depends on many variables. Generally, you can store thousands of small items or just a few hundred larger ones in any storage system. Size is the most important constraint, but there are other factors. Carousels and VLMs are used to store and retrieve everything from tiny aerospace parts to massive gearboxes, so the quantity of any individual item—or a mix of them—varies by load.

Above: carousel tray configurations including dividable components, totes and bulk steel parts

Load characteristics/dimensions

Load characteristics (size, weight, balance) are a primary factor in overall storage capacity. In general, the larger the item, the fewer you can store in a carousel or VLM. These systems are flexible and can store many items of various profiles within them, so the calculations are difficult without specific load data. Tray sizes are directly affected by enclosure size (see below).Tray or container design

Tray design: Tray designs include carriers, bins or sliding shelves that affect the number of stored items. Trays can be designed to slide out, to host tiny containers, to detach to mobile tables and much more. Lean-Lift trays support loads from 400 to 2,200 pounds; Rotomat trays hold up to 1,100 pounds.

Total load weight

This is usually less of an issue than load size, but can still factor in. Lean-Lift maximum payload can be as high as 132,277 pounds (60,000 kilograms) depending on the specific VLM configuration. Rotomat standard models list maximum capacity of 35,494 pounds (16,100 kilograms)

Carousel/VLM dimensions

Enclosure dimensions also dictate item count. Standard Lean-Lift enclosures can be as large as 175" wide, and up to 50" deep. Rotomat widths range from 102 to 135", with depths from 39 to 68". Heights are configurable to your ceiling and can greatly affect item capacity.

Height-sensing technologies affect item load capacities

As containers enters the storage area, sensors scan and record the vertical dimensions. The VLM adjusts to use the least necessary vertial space to store each SKU.Another factor that affects item storage capacity is adjustability. Hanel VLM height sensors dynamically adjust carrier heights to load heights—meaning that the system helps you maximize storage within the unit.

Can carousel systems operate in clean rooms?

Yes. Carousels and VLMs are used in clean or controlled environments.

CleanStore particle-controlled Rotomat systems are built for low-particle storage of components in clean-rooms. This lets you take advantage of carousel to store and distribute sensitive components like electronics or semiconductors. Carousels can also store substances like pharmaceuticals, chemicals and others for controlled environments.

Can carousels operate in cold storage or high heat environments?

Yes. In the correct use cases and within tolerances, carousels and vertical lift modules can operate in cold or hot environments.

- Rotomat vertical carousel systems operate from -4 degrees to 140 degrees F (-20 degrees to +60 degrees C)

- Lean-Lift VLMs operate within tolerances of from -32 degrees to 140 degrees F (0 degrees to +60 degrees C)

- Reliable temperature constancy to ± 33.8 degrees F (1 degrees C)

- Hänel offers powered storage containers for storage at extremely low temperatures, down to -80 degrees C/-112 degrees F. This lets you store cold boxes within the carousel or VLM.

Hänel DryStore and ClimateStore systems make their systems suitable for almost any air-controlled environment. Systems can be freestanding or installed to integrate with existing spaces. They can integrate with high-speed doors or other control systems.

Installation, power and maintenance

What are the space requirements for vertical carousels and VLMs?

Vertical carousels and vertical lift modules minimize floor space by using your facility's vertical height. Both systems consolidate storage into a single footprint and eliminate access aisles. Both have a range of enclosure sizes and heights and can be customized to fit nearly any situation. Carousels require maintenance and repair space near the unit, typically from the front side.

What are the maximum heights for VLMs and vertical carousels?

VLMs are highly configurable and can be extremely tall, with maximum heights reaching 60 feet. A single VLM can serve a multistory application with multiple access points. Common tray widths range from 4 to 13 feet, with depths of roughly 2 to 3.3 feet.

Rotomat carousels are built to fill the vertical space in most high bay ceiling facilities. Typically, they can reach heights up to 30 feet.

What are the power requirements for a Hänel carousel or VLM?

Power requirements vary by system size and configuration and are defined in manufacturer technical data.

How long does it take to install a warehouse carousel?

Installation time depends on system size, height, configuration, and site readiness. Read more: Carousel & VLM Installation

What are the maintenance requirements for warehouse carousels?

Maintenance typically includes routine inspection, cleaning, and servicing of mechanical and control components. Annual inspections are required for Hänel systems.

We document the various steps for carousel and VLM maintenance programs below:

- Hänel Lean-Lift VLM Annual Maintenance

- Hänel Lean-Lift VLM Safety Inspections

- Hänel Rotomat Carousel: Annual Maintenance

- Hänel Rotomat Carousel: Safety Inspections

Cisco-Eagle Field Services provides comprehensive service, mainenance, inspections and repair for Hänel systems

Controls and software questions

Read more: Carousel and VLM control systems

What control systems are available for Hänel Lean-Lift and Rotomat systems?

Hänel vertical storage systems use dedicated microprocessor-based controllers to manage storage, retrieval, and system operation. Controller options vary by configuration and may include touchscreen interfaces, user management functions, and integration capabilities with external software systems.

Standard controllers include:

- MP 0 N: Single lift basic controller for Hänel Rotomat systems. Ideal for smaller operations and fundamental storage needs.

- MP 14 B: Intuitive controller with with an 8.4-inch (800 × 600 pixels) display Includes integrated StandAlone mode, which controls a single lift, making it the ideal single-user solution. Includes integrated storage management software.

- MP 14 N: Full-color 12" touchscreen for mid-size warehouses. Features intuitive interface, ERP connectivity, and reporting features. Operating modes include StandAlone, HostCom, HostData and HostWeb.

- MP 100 D: An integrated central control system for up to 99 carousels or VLMs. You can control sophisticated full systems with capabilities for 100,000 part numbers in up to 400,000 storage locations to service up to 4,000 pick lists, job lists or parts lists. Standard ethernet interface connects your data to ERP or WMS. A key feature is the travel time optimization that reduces walking to the minimum. Allows control of every lift either simultaneously or independently

Count on Cisco-Eagle to help you integrate Hänel systems into your operation, ensuring smooth communication between your lifts, your existing storage or picking systems, and your digital inventory tools.

What controller modes are available for Hänel vertical storage systems?

Controllers manage system movement, tray or carrier positioning, and user interaction at the access opening. They help streamline picking operations and reduce manual search time.

Hänel vertical storage systems offer multiple controller modes to support different levels of system integration and data management:

- Standalone Mode: Ideal for single unit systems. The carousel operates independently using its onboard controller. Inventory data and system control are managed directly at the machine without connection to an external host system.

- HostCom Mode: The controller communicates with a higher-level host system for data exchange while maintaining certain control functions locally. This supports coordinated operation within a broader warehouse or enterprise environment. Ideal for remote monitoring and configuration.

- HostData Mode: Inventory data management is handled by an external host system, with the controller serving as the execution interface for storage and retrieval operations. Connects directly to external databases for automated updates, synchronization, and data sharing.

- HostWeb Mode: Lets you use web applications directly at the lift. Web-based connectivity allows communication between the Hänel system and host systems through network infrastructure, enabling centralized control and data exchange. You can design virtually any user interface you need.

These controller modes let you configure Hänel systems for standalone operation or varying levels of integration with warehouse management or ERP systems.

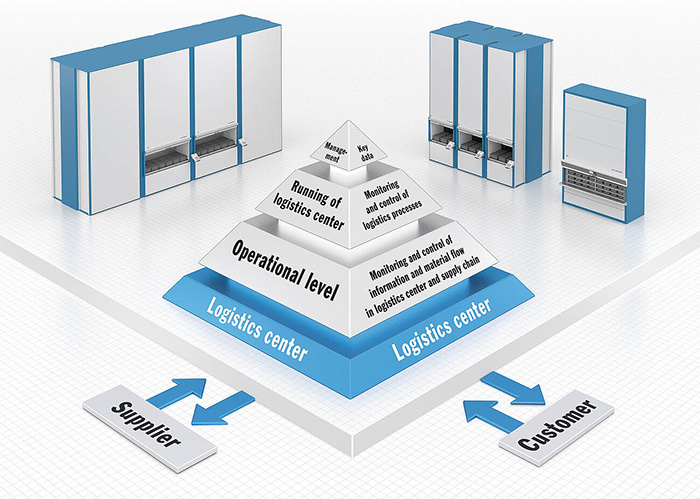

How do Hänel systems integrate with warehouse management systems (WMS), ERP and other software platforms?

Extensive integration capabilities drive the versatility of these systems.

You can integrate Hänel systems with your Warehouse Management System (WMS) and ERP systems to coordinate storage, retrieval, and inventory processes. Integration allows real-time data exchange and process monitoring, and the system can connect with leading ERP platforms, including SAP and other major provider to streamline information flow, material movement, and warehouse workflows. Web-based technology means you have a middleware-free link between the Hänel controllers and many ERP solutions.

Hänel TDM drives efficient tool management. It helps reduce confusion when visually similar tools are stored in the carousel and drives better tracking and verification. You can trace usage down to single users.

MP-Link 2.0 drives efficiency for automobile dealer management systems. This links inventory reporting, dashboard activity, transactions and tickets. It lets you gather the total value of stored inventory in your system. Direct standard interface with DMS vendors (like Procede, Auto/Mate and DSI).

Integration enables data exchange between the vertical storage system and broader warehouse operations. Cisco-Eagle and Hänel evaluate integration requirements during system design to ensure compatibility with existing software environments.

What is Pick-o-Light, and how does it improve picking accuracy?

Pick-o-Light is a light-directed picking system that guides operators to the right storage location within a carousel or VLM tray or carrier. Like other light-directed systems, it helps people find what they need quickly and accurately. It was specifically created to optimize Hänel systems.

How it works:

- The system projects a colored LED beam of light directly onto the requested SKU. It's an unmistakable signal that guides operators to the right piece.

- Pick-o-Light uses a fixed raster. It lights the corners to differently-sized compartments to identify the compartments.

- The lights move along two axes so it can cover entire trays.

- Optional reticle helps target very small items.

Visual indicators highlight the pick position, helping reduce search time and support picking accuracy. When integrated with system controls and software, Pick-o-Light supports organized, guided picking processes within Hänel Lean-Lift or Rotomat systems.

How does Cisco-Eagle support controls and software integration?

Cisco-Eagle provides system design, integration planning, and implementation support for vertical storage controls and software in partnership with Hänel. This includes evaluating workflow requirements, assessing compatibility with existing systems, and coordinating installation and commissioning.

By combining equipment expertise with controls and software integration support, Cisco-Eagle delivers a complete, functional storage solution rather than standalone equipment.