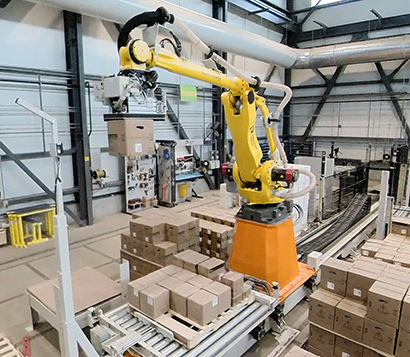

Automated palletizing is one of the best places to target automation because the process is so manual and heavy duty for many companies.

Why? Because it helps you reduce one of the least value-add parts of your operation: stacking and creating pallets. Doing that manually makes less sense every passing year for companies that are already working to reduce dependency on an ever-contracting labor pool. To get the process started, start by focusing on your operational needs, customer base and labor factors.