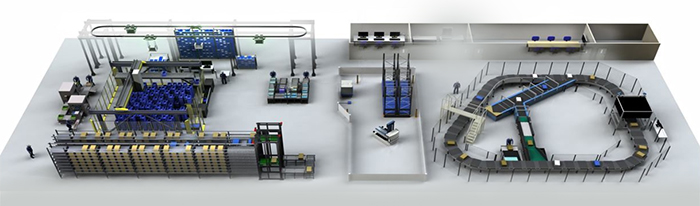

Pick modules are commonly used in distribution operations when companies need to build high-density, high-throughput order fulfillment operations. This typically involves a multi-level platform system integrated with vertical storage options to move finished orders on and off platform levels toward other warehouse destinations.

One overlooked aspect is the addition or removal of empty cartons to picking positions. What are your options?