Online sales will account for 17% of all U.S. retail sales by 2022, up from a projected 12.7% in 2017. As you might imagine, warehouses are suffering from a major capacity crunch. Whereas previously warehouses were organized to handle large volumes of each product, E-commerce orders are characterized by a low quantity of many items or just a singular item. In an e-commerce oriented warehouse, huge quantities of SKUs exist, each needing their own specific storage slots.

Warehouse managers know that inventory levels can fluctuate anytime within a sales season, especially during a holiday when inventory levels are typically at their peak, often double or triple normal levels. Plus, because of the Amazon-effect, consumers are demanding more products with faster and better service, putting additional strain on warehouse space. Because of this growth, many businesses are looking for additional space to distribute and store products, but warehouse real estate is hard to find.

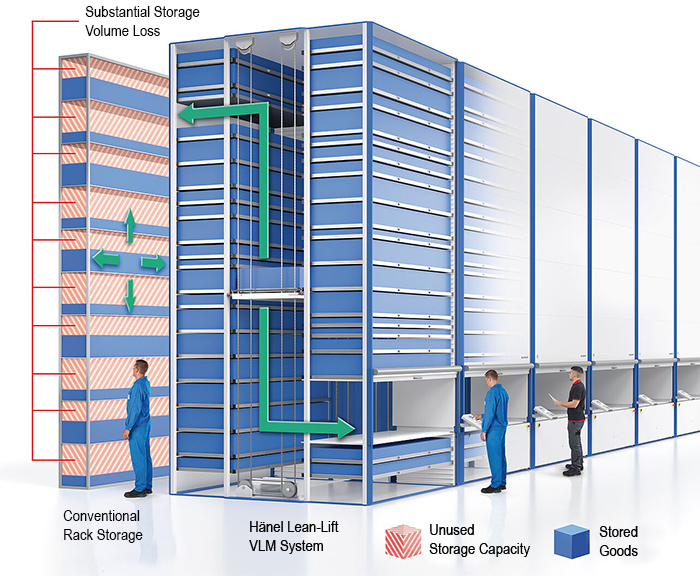

What is a retailer to do? The answer for additional space can be found within the four walls of your current operation.

Read the rest of this entry »