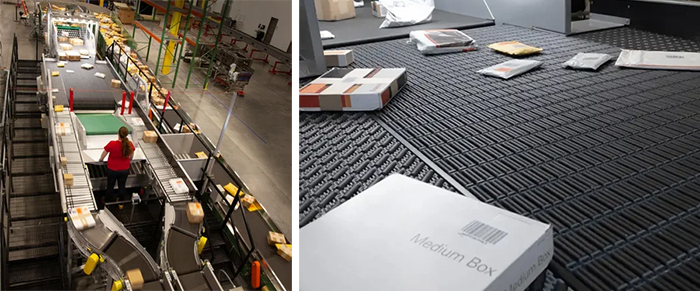

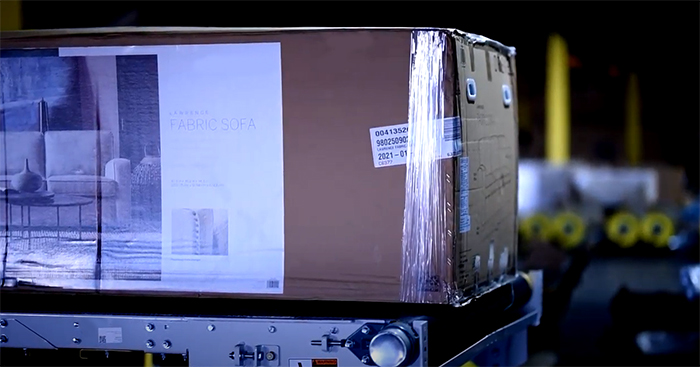

Loading and unloading pallet conveyors with forklifts is an everyday, all-day task.

Done right, it’s fast and efficient. Done wrong, product damage, collisions, injuries, and workflow bottlenecks happen. I’ve seen it in dozens of warehouses, even in highly automated operations, and most of them tend to bridge the shipping dock and the end conveyor lines with forklifts (these days, AGVs and AMRs often do this work). Pallets are large, heavy and in motion when they’re transported on conveyors. That combination of size, pressure and movement can result in damage or injuries when not properly controlled.