How to Singulate Products on Your Conveyor System

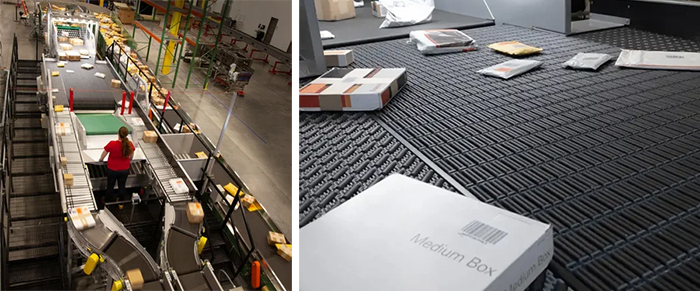

Singulators descramble products into single lines

What is singulation?

Singulation separates and single-lines cartons and other loads into lines as they move on a conveyor. Bulk and parcel applications frequently require singulation. Conveyors and control systems use multi-speed belts, dedicated singulators, skewed rollers and side-driven motors to unscramble multiple lines of products into single-file. Think of singulation as the process of organizing cartons or other loads into a single, neat line for future processing.

Singulation is pivotal for in sorting and organizing materials ranging from boxes to fragile electronics to sturdy automotive components on conveyor systems.

Singulation for manufacturing and distribution applications

Deployed singulation upstream of other processes:

- Gapping: some singulators function like gappers, but can also serve to force loads into single-file for gapping needs in bulk flow applications.

- Packing: when bulk flows of product must be handled by packers, you need a single line flows of work. Singulation merges these loads into an organized queue for processing.

- Packaging: automated packaging machinery (tapers, void fillers, dispensers, labelers, etc) require single package alignment.

- Sortation systems: align your products prior to entering a sortation process.

- Scanning: singulate parcels, totes and other loads ahead of a scanner for accurate reading.

Singulation separates, aligns and organizes conveyed loads

Parcels, packages or other loads emerging from a belt conveyor system often require alignment for the next step in the process, whether that is another conveyor line or a process machine. Accomplish singulation with solutions ranging from:

- High-speed automated singulation systems

- Merge lanes outfitted with skewed rollers that force the load to one side

- Paddles or pushers that gently nudge parcels into line

- Diverters of various sorts can act in some ways as singulation devices

- Multi-speed belt systems that space out items on the conveyor as it moves

- Sensors and control systems designed for singulation

- Using brakes in accumulation zones to control product positioning. They stop the load’s forward inertia to prevent jumbling

- Systematically release products onto accumulation zones in cascade mode, which allows you to place small gaps between loads with momentary delays for each item.

Read more: Accumulation and singulation

Don’t allow jumbled product flow

Singulation links different stages of transport and production by ensuring that the conveyed load moves seamlessly without clumping. It’s used in various process steps for ecommerce, parcel and retail distribution operations. When precision and position are critical, so is the singulation method. If packages must align and space, or components must be in predefined positions, then your system must be able to singulate your conveyed loads at the right time, in the right place.

Slow it down: conveyors running at very high speeds can achieve fast throughput, but may also cause the loads to jumble or bounce, rather than flowing in single lines as desired. Slowing your flow, when possible, is one of the best ways to prevent side-by-side and jumbled cartons on a line.

Singulation using skewed rollers

Installing skewed rollers after a merge point squares cartons and prevent them from bunching up needlessly. Skewed rollers will move all cartons to one side past a merge point, which can force them into a single line.

The side-by-side problem

Effective systems design and singulation prevents loads from drifting next to another carton on the system.

Side-by-side (sometimes called “shingling”) loads bog down conveyor systems, cause jams and slow you down, but singulation machinery isn’t a magic bullet. Expensive singulators shouldn’t be used to solve problems you can solve less expensively with a more thoughtful system design.

One of the most common singulator applications is to solve side-by-sides — where cartons or other loads sit parallel to each other on a conveyor line. There are other methods that can solve that issue that should be considered before placing a dedicated singulation system. Finding ways to unscramble your loads on a system is better than fixing it with expensive equipment. Some of the ways to do this include:

Dedicated singulator devices are costly, occupy space and require maintenance. They have their place, but shouldn’t be used to solve problems that can be solved more economically. See Cisco-Eagle’s skewed conveyor roller calculator for more details.

Manual singulation

This is the slowest and least effective method, but, it’s effective for slower throughput operations. For instance, in truck unloading applications, warehouse workers often pull boxes out of stacks or off pallets, then place them on extendable or flexible conveyors for takeaway. These workers are doing simple singulation by placing the loads correctly on the conveyor. Manual singulation by nature slows truck unloading or other operations, but can be a viable solution in the right configuration.

Read more: The Ergonomics of Flexible Conveyors

Mixed parcel system

These dedicated singulation machines singulate multiple types and sizes of packages or other loads with cartons as small as 4″ x 4″ to almost any maximum size. . This singulation solutions handles maximum sized loads of almost any size, depending on other conveyor factors. Throughput is range from 4,800 cartons an hour for loads of varying sizes. If your cartons are similar dimensions, it’s even faster: 12,000 cartons/hour.

Above: the ARB Mixed Parcel system singulates products gently and efficiently.

Smart singulator

The Intralox® Smart Singulator transforms messy and disorganized bulk flows of various-sized and various-shaped parcels into one line of items. It uses sensors and ARB technology to accomplish this at high speeds.

Designing singulation in…or adding it as the need becomes apparent

If you’re working on a new operation or a strategic expansion, baking the singulation process in is the best approach. However, altering an existing operation to singulate as new equipment, inventory, processes and machinery are needed is also workable. Sometimes your system will start to require singulation as load sizes, weights and shapes change. You may find that manually dealing with those flows is impractical. Adding singulation in a thoughtful, strategic manner will ensure faster, more accurate product flow, fewer errors, less product damage and more satisfied customers.

Tags: Automation

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.