How to Use Conveyors for Ergonomic Truck Loading and Unloading

What systems are available - and how can you use them?

We recently discussed the various ways you can use conveyors to optimize the end of the line, which includes the ways they interface with trucks and trailers. The transition between the end of a conveyor system and the trucks where goods are loaded or unloaded are one of the areas where distribution centers can struggle. The traditional method has been to throw labor at the problem, but as we know in 2023, that is becoming a less useful and more difficult option.

Extendable conveyors are the preferred method for trailer-warehouse transitions

Using extendable systems works very well by creating the transition you need between conveyor lines and docks. It’s constantly done in a variety of industries, particularly where the truck must be cubed out with cartons. Without an extendable conveyor, companies must manually remove cartons from the conveyor line and then move them afoot into the trailer, which is an extremely labor-intensive process with terrible ergonomics.

This is a spot where automation works right up to the point of use: most of the time, people are required to remove boxes from the conveyor and stack them logically into the trailer.

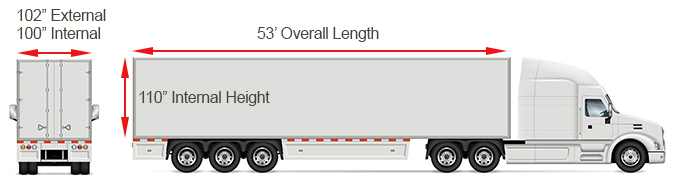

Most over-the-road truck trailers are 110 inches tall (internal), and 100 inches wide. Workers have two issues to contend with: first, that’s a lot of area to cover and most of it isn’t in the ergonomic golden zone between their knees and chest. Secondly, they are also expected to stack cartons in logical sequences that reduce product damage and facilitate unloading.

If you’re receiving carton-filled trailers, you’re doing the opposite–pulling cartons out of a stacked trailer and placing them on an extendable conveyor, the same issues exist in reverse.

Lower vs. higher volume

If you’re operating at lower volumes, manual methods may be adequate. Palletizing cartons, then moving them into or out of a trailer with a pallet jack can work well for LTL shipments in lower volumes. But if you’re shipping out significant volumes of cartons for retail or ecommerce distribution, that quickly becomes labor-intensive and slow.

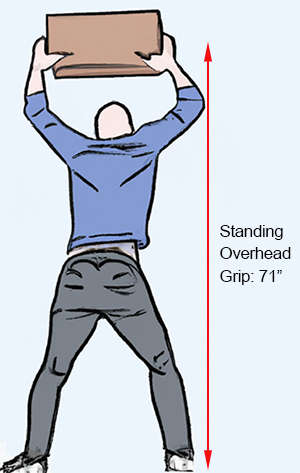

- If you’re stacking cartons up to the full height of a trailer, then people are reaching well above their heads to position them.

- That reach can pose significant ergonomic problems, particularly at high volumes and with heavier cartons that can strain workers.

- If you’re stacking to the floor, then workers are bending over while holding cartons in potentially awkward positions.

The average person has an overhead grip of 71 inches. This means that the top layer or two of any trailer will require them to reach higher than recommended to cube out.

Adjusting trailer loading & unloading to ergonomic heights

Optimizing the height dimension to reduce stretching, strains and bending

Ergonomic, adjustable truck-loading conveyors let workers adapt to the task in two different, ways: First, they can elevate the worker vertically, which puts an end to the overhead reach problem. Secondly, its conveyor adjusts to match the height of the current layer of cartons to be stacked or unstacked. In both ways, it reduces the stresses and strains of dealing with scores of cartons in truck trailers.

The system is portable, so warehouses do not necessarily need to have one available for every dock door.

Videos

Time and labor savings

Another factor is the time saved by making loading and unloading easier. We’ve extensively covered warehouse ergonomics in a number of places, and it’s a constant: Making a process more efficient, less labor intensive and faster. Using a “right height” system like these unloaders can cut the time it takes to unload a trailer by half. Because trailers are dark and usually hot, this helps you reduce the number of people it takes to execute the process.

More on warehouse ergonomics

- Ergonomics and Pallet Handling

- Improve Productivity with Ergonomic Storage System Design

- How to Use Conveyors to Increase Warehouse Ergonomics

Tags: loading docks, Receiving, shipping, labor, ergonomics

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.