Spot The Mark – Why Floor Marking Is Essential

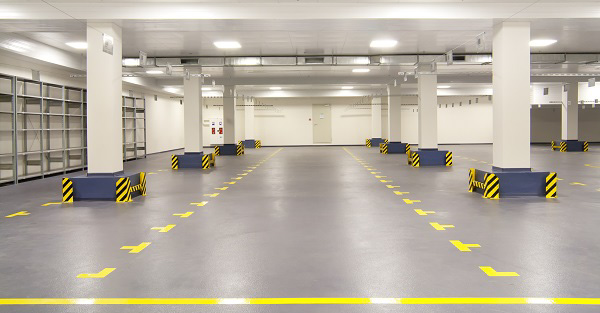

Proper floor marking can help improve safety and organization in your facility

As we navigate this new age of Covid-19 and the distancing associated with it on all fronts of our lives, keeping areas within your facility safe and spaced becomes not only a priority now, but leads to further efficiency for operations in the future. Operations that utilize efficient means for creating visual clues within their warehouse showcase a more productive work environment that also keeps employees and equipment free from potential hazards.

One method to aid in this endeavor is floor marking. By marking areas in your facility, you highlight risks, outline areas for equipment and people, direct traffic and showcase safety considerations. In short, just by adding some color to your floor, you make your entire facility easier to navigate.

The advantages of proper floor marking in your facility are numerous

Organization first and foremost

While it might seem like an afterthought or a lesser concern, marking your floor can lead to multiple benefits. A well-organized facility simply performs better, and by using floor markings you can provide your operations with more efficient spacing and caution. Any increase in warehouse organization will reduce wasted time and energy. A great example would be utilizing bulk storage floor markings—where certain equipment, supplies, pallets or raw goods are stored—and pairing them with overhead barcode signs for efficient tracking and management.

While it might seem like an afterthought or a lesser concern, marking your floor can lead to multiple benefits. A well-organized facility simply performs better, and by using floor markings you can provide your operations with more efficient spacing and caution. Any increase in warehouse organization will reduce wasted time and energy. A great example would be utilizing bulk storage floor markings—where certain equipment, supplies, pallets or raw goods are stored—and pairing them with overhead barcode signs for efficient tracking and management.

Another benefit is that marking creates a clean, clear layout for the placement of warehouse goods and equipment. Using 90-degree angle tape can help employees know where to place pallets, equipment and carts, while also providing highlighted parking areas for industrial vehicles such as forklifts. Their ability to be removed and re-organized as a facility grows or changes is a distinct advantage over painting your floors as well.

Safety considerations

While organization is certainly a benefit from administering a floor marking system, consider safety as another way to use tape. Adding this practice to your operations offers many protections:

- Separate workers from machines and moving equipment: Use floor marking to designate paths that protect pedestrians from forklifts, electrical panels, heavy machinery, and other hazards.

- Warn of hazardous areas: Keep employees safe on loading docks around dangerous equipment and around areas with exposed edges.

- Provide instruction: Let employees know where to stand (or where to avoid) when operating heavy machinery and other equipment.

- Improve forklift safety: Forklifts are fraught with hazards. Floor marking can establish pedestrian-only paths, keep employees away from imbalanced or unsafe loads, and establish traffic controls for drivers.

- Keep employees safe in low-light conditions: Photoluminescent floor marking can help employees find exits and equipment in emergencies and other low-light situations.

OSHA addresses floor marking specifically in its standard on materials handling and storage, with statements and guidelines for aisles and passageways. While there are no standard colors required by OSHA, aisles, forklift lanes and work cells must be clearly marked. The color suggested through 5S Lean standards is yellow. 5S Lean standards also suggest other color coding practices for consistency and clarity in meaning within a facility.

Also, in this new age of Covid, administering floor markings to ensure social distancing between workers is an added value that can be used to protect workers from each other, and keep employees safe and potentially virus-free while on the warehouse (or facility) floor.

Navigating your employees and visitors

You want a free and clear path for both workers and visitors at your facility, and marking your floors in that manner reduces travel time, improves efficiency and protects people from potentially hazardous situations. By using the tape to establish aisles for pedestrians and vehicles and directing the flow of traffic; you can your people get where they’re going in a safe, efficient manner. Adding items like footprint tape can also alert those traveling along these guided paths of emergency exit ways and “safe” areas should a situation arise that calls for quick movement towards protection.

You want a free and clear path for both workers and visitors at your facility, and marking your floors in that manner reduces travel time, improves efficiency and protects people from potentially hazardous situations. By using the tape to establish aisles for pedestrians and vehicles and directing the flow of traffic; you can your people get where they’re going in a safe, efficient manner. Adding items like footprint tape can also alert those traveling along these guided paths of emergency exit ways and “safe” areas should a situation arise that calls for quick movement towards protection.

Floor marking covers many areas for a warehouse and can provide an extra level of safety and efficiency that any operation can use moving forward. Add to that its potential for social distancing and protecting against virus spread, and this minor investment can yield great results.

More Resources

- Social distancing on the warehouse floor

- Why the floor is better for forklift warnings

- Guide to measuring your facility

Evan Fleishacker