Configuring a Forklift Warning Light

Your lights must be set consistently across all vehicles in a facility to help pedestrians understand distances

When it comes to pedestrian safety in warehouses, the problem can be plain old attention span

People who aren’t paying attention are at the most risk, particularly those who walk near and around forklifts. People don’t pay attention because they’re busy, worried about deadlines. Or they’re absorbed in their smart phone, or in a conversation with someone. The reasons vary, but when forklifts are involved, the results can be deadly.

Most experts agree that the key is training for both the pedestrians and forklift drivers–and that’s true–but shouldn’t be the end of the story. You should enhance training with various facility and equipment upgrades. That’s why many companies have installed forklift warning lights, often called “blue lights”, that project a disc of light that precedes the forklift as it moves. Since the forklift is typically the most dangerous piece of equipment in any facility that uses it, these types of low-cost enhancements are sensible and easy.

The blue lights are highly effective in part because they are “disruptive”. Unlike tape or paint lines for traffic management, or static signage, they aren’t always there. They don’t mentally blend into the background as easily as safety precautions that are seen all day, every day by warehouse employees.

Since these lights are installed on so many forklifts, it’s important to understand exactly how they should be mounted for maximum effectiveness.

Read more: Why the Floor is Better than Eye Level for Forklift Safety Warnings

Recommended forklift warning light settings:

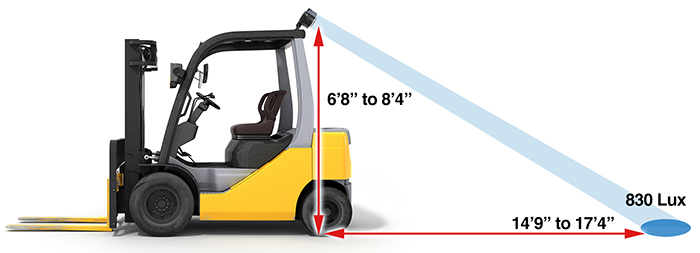

- Recommended Placement: Front and Rear of the vehicle

- Recommended Beam Pattern Intensity: 830+ Lux (on the ground)

- Recommended Mounting Height: 6’8″ – 8’4″ (2.0m – 2.5m)

- Recommended Beam Pattern Distance (from Vehicle): 14’9″ – 17’11” (4.5m – 5.5m)

It’s important that once you have installed the lights, that you check them for distance. If the light is tampered with, or moves, it can affect its distance. Pedestrians who are used to a certain “lead” distance will assume the forklifts are always set at that distance, so consistency of distance, and consistency across all vehicles is important. A change in that distance can lead to dangerous assumptions on the part of pedestrians.

More resources

- See all Forklift Warning & Safety Lights

- Video: A Guide to Forklift Safety and Warning Lights

- Cheap Forklift Warning Lights Could be Incredibly Expensive

Download our guide to forklift accessories

The right accessories make your forklifts safer, more efficient and more productive. We believe that every forklift and warehouse can work better. Our employee-owners share tips, articles, links and more to help you make the most of your warehouse in our forklift accessories guide. We’re here to help you work safer, smarter and more productively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.