Get Your Pushback Rack Load Right

Be sure you are using the right pallets and load types to avoid issues

Push back rack systems are excellent high density storage solutions — perhaps the most economical way to squeeze space out of a crowded warehouse. All loads are stored and retrieved from the same aisle. This reduces the number of aisles needed in a facility, freeing up more space for storage. Aisles can take a great deal of space up in a typical warehouse, so by implementing a pushback pallet rack system, you essentially swap selectivity for space. Push back rack systems provide a Last-In-First-Out (LIFO) inventory rotation, so you have to be certain your load fits. If it does, congratulations — you’ve just saved a lot of space.

But there are issues that can arise when pushback rack is inappropriately specified or utilized.

You must load your rack with the right pallets

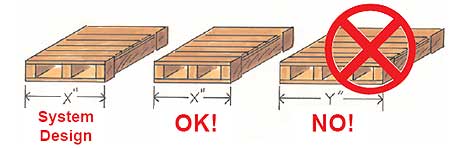

Once a push back system is installed, it’s critical to be sure you use the right pallets.

It’s very important to know the type and size of pallet the rack was designed to store. Push back systems are designed to handle pallets and loads of a particular size and weight. For example, if your push back cart was designed to use 40” wide by 48″ deep pallets, do not use pallets that are longer or shorter than this size.

Using pallets that were not designed to be loaded into the system can lead to:

- Cross Stacking: (a pallet is resting on two different carts); this will cause a jam or potentially damage the carts, your load, or both

Under utilization of the systems full capacity

Under utilization of the systems full capacity- Damage to the cart system and possible damage to the product being stored

- Jams: defective or damaged pallets may not allow the push back system to operate correctly

- Hangups: Overhanging loads are almost guaranteed to cause the cart to hang up and your system to jam. Worse yet, they can be a safety hazard as items fall out of the rack.

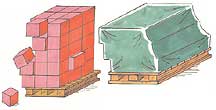

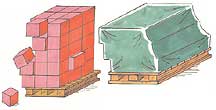

What should the pallet look like?

- Most of the time, pallets should be GMA style with at least five (5) bottom boards running left-to-right

- Pallets should also be shrink-wrapped or securely banded before you place them in a system

- Loads shouldn’t overhang the pallet on any side, including slip sheets, shrink wrap, carton flaps, improperly stacked boxes or other factors

Loading capacity consistency

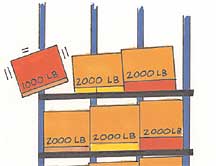

Pushback racks are about uniformity — of load type, pallet type, and load weight. Pallet load weights, in a single push back lane, should not vary by more than 500 pounds, even if the rack can accommodate the weight of heavier pallets. Don’t store a 2,000-pound load in the same push back lane as a 1,000-pound load.

Pushback racks are about uniformity — of load type, pallet type, and load weight. Pallet load weights, in a single push back lane, should not vary by more than 500 pounds, even if the rack can accommodate the weight of heavier pallets. Don’t store a 2,000-pound load in the same push back lane as a 1,000-pound load.

Similarly, push back rack systems are not intended to be used for applications where the aisle-side pallet is “picked.” Removing cartons reduces the load weight of the last pallet in the rack and may cause the inside pallets to push the aisle pallet out of the rack. Loading pallets of varying weights within the same lane may cause the heavier loads to push the lighter loads out of the rack. That means product damage, injuries, or worse. Be consistent with your loads. They should be alike in as many ways as possible for pushback rack to work correctly and safely.

Bottom line: If you have pallet loads that vary by 500 pounds or more, designate push back lanes to handle common load weights.

Most rack manufacturers have extensive usage guides. These tips are general guidelines, but you should always refer to your rack manufacturer for exact tolerances and specific specifications. If you can’t find the manual that came with your rack, many websites will have them in PDF form. We will help you hunt one down if you need assistance.

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners.

You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.

Under utilization of the systems full capacity

Under utilization of the systems full capacity