Wire Shelving Advantages Over Standard Shelving

Versatile, multi-purpose and sleek - with a broad range of industrial applications

What specialized applications do you have for shelving? Cold storage capable? Biohazard resistant? Air flow through shelves? Fire sprinklers able to reach all levels? Bin storage and easy visibility of shelf contents? All these are great reasons to go with wire shelving, which can serve multiple purposes in a facility and is less likely to retain airborne dust and debris.

Let’s look at some of the wire shelving options available.

Diverse configurations built on a basic construction style

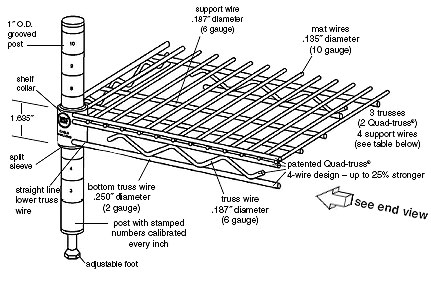

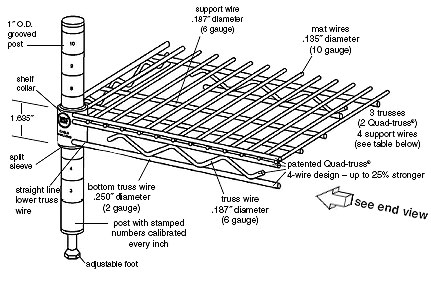

Wire shelving is constructed of steel posts or uprights and sturdy wire reinforced shelves made up of horizontally running support wires overlaid with front to back running mat wires to create a mesh pattern. On the front and back of each shelf a wire truss structure provides reinforcement against shelf sag.

When the unit has adjustable shelves, each post or upright usually has incremental shelf position markings on the post where shelf retainers are placed to support each shelf at the desired position. Often casters or wheels are added to the unit to give it mobility.

Taking a basic structure to new functions and uses

The basic wire shelf structure is compatible with many usages from hospital mobile carts to warehouse order fulfillment and product storage. In fact, any time traditional shelving doesn’t answer your storage optimization needs, take a look at wire shelving. It offers many advantages over standard steel shelving.

Cold storage and condensation

The key advantage wire shelving offers in cold storage applications is the flow-through ventilation that allows cold air infiltration through all levels of shelving, directly impacting the quality of storage a product receives. Also, because of the flow-through feature, far less condensate builds up on shelves because the condensed particles are more quickly evaporated back into the chilled air.

Bin storage for parts storage and pick operations

Because of the lightweight characteristic of wire shelving, it is easy to put it on wheels with pick bins or wire baskets on the shelves and move it around a warehouse space. This allows for batch picking, ease in transporting picked goods and also storage replenishment.

Small parts storage becomes more dense yet remains highly visible because shelves can be placed where needed to more completely use the vertical storage capacity. Also, with bins, parts are easily changed out as product runs change or modifications are made.

Retail storage that has a sleek, clean look

Wire shelving is a strong component of many retail product displays. You’ll see it used in clothing stores, gift shops, hardware and self-improvement centers, to mention just a few. The advantage here is high product visibility from the open mesh design plus the clean lines and low dust accumulation on shelving parts.

Excellent shelf capacity, fire suppression and finish characteristics

Wire shelving generally ranges from 600 to 800 pounds capacity. These capacities depend on loading patterns, shelf width and depth, so be sure to check the manufacturer’s capacity ratings before you load it up.

One of the best characteristics of wire shelving is its ability to allow water from overhead fire sprinklers to flow through to shelf content, helping to suppress the expansion of fire through a facility. Another advantage is the flow-through ventilation aspect wire shelving offers. In applications where air flow is important, such as agricultural and other industries, wire shelving allows the most ventilation of all shelving types.

Finally, the variety of finishes available gives wire shelving some distinct advantages over all other shelving. For healthcare environments a bio resistant finish helps to suppress the passage of dangerous viruses and bacteria through the facility and stored contents. In high humidity environments a special moisture resistant finish keeps rust and corrosion at bay, extending the useful life of the shelving in those environments. Some finishes are even FDA food grade approved.

There are finishes resistant to chemicals, acid, rust and corrosion. Anti-microbial agents can be added to finishes to suppress bacteria, mold and mildew. Consider stainless steel wire shelving for washdown applications and NSF approval. For greater durability, chrome and black epoxy finishes lengthen shelf life and pleasing appearance.

Wire shelving offers solutions to many storage issues

The next time you audit your storage systems, add wire shelving to your list of possible solutions. It offers many advantages and benefits over traditional shelving while providing a clean, sleek look that is space saving as well.

Tags: zinc, epoxy, finish, stainless steel, sprinkler, ventilation, wire shelving, chrome

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.