How to Increase Conveyor Longevity

Specify, use and maintain your system

Conveyors–as we’ve discussed–have two major costs:

- The cost of conveyor hardware, which should include installation.

- The cost of operations, which should include maintenance, repair and energy consumption.

When you invest in capital equipment, you should be as focused on operational costs as purchase price. Part of that is extending the life of your conveyor system. How can you make sure you get the most out of your conveyors?

It’s important to know when to pull the trigger on replacement. But if you specify the right conveyors, use them in the right applications, use quality components and maintain your system, you can get the most from your investment for the longest period of time.

Conveyors specified for the application last longer

Conveyors that aren’t suitable for the job either won’t do it well or won’t do it long, or both.

When any machine is asked to do things beyond its design, stresses and strains will reduce its lifespan. Your conveyors should be specified correctly not just for the load you have today, but also for potential loads the system might have to convey down the line. Designing for future growth is crucial for e-commerce operations that experience changes in picking patterns and SKU mix. Well-designed conveyors correctly balance loads and don’t create instances of stress on any part of the system. Drives that overheat or over-torque are under undue stress that can cause critical failures.

Most importantly, the wrong conveyor in the wrong application won’t offer the efficiency you need, even if it continues to work.

See: Conveyors in Difficult Environments and A Guide to Loads and Applications

Using inferior components means shorter lifespans

There are plenty of high-quality conveyors on the market, and they all accept a variety of components and spare parts from a number of sources. Most conveyor manufacturers build their systems with a specific size and type of reducer or chain or belt or pulley in mind. Make certain that you replace existing items with the right components that meet manufacturer specifications. Good components cost more, but they pay off in the end, not only with longer life, but with less downtime and fewer repairs to the system.

The savings on low-quality components are meager compared to their effect on longevity and reliability.

Conveyors last longer when operated as intended

If your system is used incorrectly, the lifespan of your conveyors shrinks. Issues can include:

If your system is used incorrectly, the lifespan of your conveyors shrinks. Issues can include:

- The wrong loads: If you place loads that are too large or heavy on the conveyor, you can damage or wear down components. If your load significantly changes, you may need to alter your conveyor to cope with it.

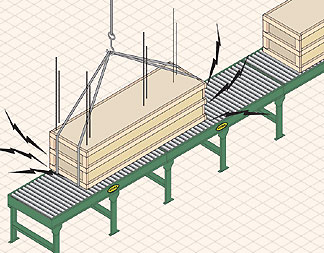

- Shock loading: Although dropping product on the conveyor is something you shouldn’t do, it can be unavoidable. Conveyors can be shock-loaded, but should be designed for that from the moment you specify them. Shock-loaded conveyors will suffer and break down due to the impacts if not manufactured to handle it. You should understand how your conveyor will be loaded or unloaded at every point to ensure you aren’t damaging your system. [See more: Conveyors and Shock Loading]

- Changing or new environments: If it’s not designed for its environment, your conveyor is likely to fail sooner than if it was designed for dust, oils, chemicals and contaminants in the first place. When you re-task older conveyor, be sure you understand the environment it came from and its new environment. If you introduce a machine that causes dust or airborne debris, your conveyors will be impacted.

- Running them outside designed specifications: For instance, if you increase the speed of your system without taking into account load and drive types, you may damage your components. We discuss conveyor speeds extensively in this article.

Maintenance should be a defined & predictable process

Conveyor maintenance should be regular, consistent and scheduled, just like your car. If your system is well-maintained, it’s going to last longer, perform better and be safer. Particular points of stress in a defined maintenance program include:

- Stop and start points

- Belting and connections

- Bearings, universal joints and pulleys should be checked and lubricated

- Electrical components, including connections to the system

- Investigate any noises or other issues reported by staff

- Anything else defined by your conveyor manufacturer

Part of the value of scheduled maintenance is its predictability. Frequent eyes and hands on the system helps you spot problems, proactively replace worn-out components and head off pressing issues. Also, talk with your operators. What’s working? What’s causing them problems? There is plenty to learn.

Your conveyor will last longer if you are systematic and consistent.

To extend conveyor life, design it right, use it within tolerance and keep it maintained

Ultimately, a system design that considers all load, environmental and application factors will extend the life of your system and allow you to get the most out of it. Proactive design and maintenance means that you’ll have a more reliable, efficient conveyor operation from day one. For questions about prolonging conveyor life, contact us today.

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.