Where to Add Warehouse Guardrails

The areas of your warehouse that paint lines can't—and shouldn't—defend may require solid protection

Facility safety for many warehouses focuses on industrial traffic and vehicles like forklifts or stackers, and no wonder—the damage that a simple mistake can do, and the people that can be harmed—is considerable. There are many varieties of guardrail systems, and they all function a little differently but have the same role: solid protection for a critical area when all else fails.

Where should you add guardrails?

Protecting people: the #1 priority

The broad guideline for guardrail placement should read: “anywhere people and forklifts interact, but can be segmented apart.” This is not always possible in today’s distribution environments, but when it is, do it. If you have an aisle that people and forklifts share, and it’s physically possible to erect a solid barrier between the pedestrian and forklift lanes, you should do so. It’s top priority. One mistake on any of the tens of thousands of times a warehouse worker and forklift share that space is enough justification for the minor expense and inconvenience.

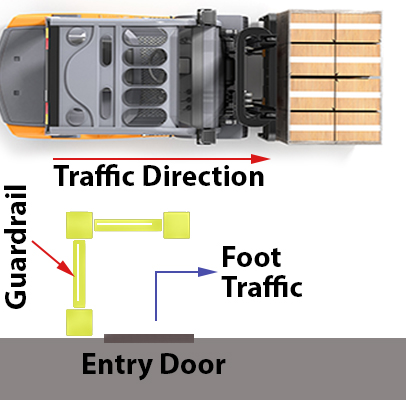

Above: illustration of a “corral” that protects pedestrians emerging from an entry door into warehouse forklift traffic aisles.

Warehouse areas to consider for guardrail protection

- Blind entryways into forklift traffic. Construct a 2-side rail “corral” that guards the door and also slows pedestrians as they enter a warehouse. You’re looking for both deterrence and guarding in this case. This could be an entry door, bathroom door, office door, etc. The idea is to prevent people from walking directly into the flow of a forklift aisle by directing them to the side, away from any defined traffic flow, before they cross or walk along it.

- Walkways and picking areas. If you have a row of shelving or carton flow in an area frequented by forklifts, run a line of guardrail in front to create a safe zone for pickers.

- Stairways and landings. A rail that protects a mezzanine or second level staircase is always a good idea.

- Workcells in forklift areas can be enclosed and defined by guardrails or bollards.

- Shipping desks near dock areas may require guards as forklifts enter/exit trucks nearby.

In any of these areas, if occasional access is needed, lift out rails or gates are available.

Picking and inventory aisles

Since forklifts are always working around your rack aisles, consider the ways you can guard them. Post protectors are inexpensive, easy to install and will pay for themselves many times over the years. Guardrail at the end of aisles is always recommended. When you have blind intersections, you can use guardrails to protect pedestrians and prevent collisions with simple guardrails.

If you have a separated general warehousing and staging area, strategic guardrail implementation can help you channel forklifts to designated openings where they enter staging, shipping or receiving. Those are areas where people frequently walk and often can’t be segmented, so creating designated entry points lets you control the flow of traffic much more precisely.

Picking areas near conveyor lines may also be a concern. Usually, these areas are not high-traffic zones, but if they are, it’s simple to protect them with guardrails.

Structural elements

Building columns, corners, walls and other facility structures should be guarded in high-traffic areas. Often a simple bollard facing the traffic aisle is adequate protection for columns. Other structural elements may include power or control boxes near forklift traffic, where an impact could cause serious downtime or other issues. Generators, server banks, and other things built into or next to walls should be guarded.

Building columns, corners, walls and other facility structures should be guarded in high-traffic areas. Often a simple bollard facing the traffic aisle is adequate protection for columns. Other structural elements may include power or control boxes near forklift traffic, where an impact could cause serious downtime or other issues. Generators, server banks, and other things built into or next to walls should be guarded.

Structural elements also include mezzanine stairways, supports and landings. Any platform where heavy weights or people work should be guarded against impacts. Always guard loading/unloading points (lifts, guardrail gaps, etc.) when possible, as you know forklifts frequent the area. Modular buildings or in-plant offices should be protected as well.

Higher value machinery and equipment

Many typical distribution centers have end-of-line palletizing functions, where a pallet is created for outgoing shipments. Depending on the facility, these pallets may be created on a conveyor, in a palletizer machine or on the floor nearby. It’s a point where several things—forklifts, expensive equipment, machinery and people often converge. It deserves special attention. If forklifts are picking up from a pallet conveyor line, guard the end of the line so that they can’t impact it. If palletizing is manual, create a guarded zone around the workers if at all possible. If a robot or palletizer is present, guard that expensive equipment.

In long runs, conveyors should be guarded as they converge with forklift traffic. Conveyors are lots more expensive than guardrails, and losing one may cripple your operation until the line is repaired. Critical areas like overhead supports should be guarded as well.

Protection is the name of the game

Guardrail systems are just part of an overall facilities and asset protection program that can involve many factors, including forklift-pedestrian safety, rack fall prevention and more.

More information:

- Download our Guide to Industrial Guardrails

- Guardrails and Impact Ratings

- How to Order Steel Guard Rail

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.