Fall Protection Mounting Methods

Find the right mounting option to best suite your fall protection requirements

Fall Protection Equipment Inquiry

Fall protection has such a stranglehold on OSHA’s yearly top 10 safety violation lists that any method to keep your workers safe at height must be a top priority.

Adding certain fall protection equipment, such as a tie-off system, provides life-saving protection for your employees. Combined with proper education and training, these systems can reduce worker falls during dangerous conditions at any height. One aspect to consider when implementing such a system is how you want to mount your fall protection. There are multiple options to do so, and each offers benefits. Which you choose depends on your working environment and needs.

Mounting methods to choose from

Let’s review some of the options available for mounting your fall protection equipment. We will explore the benefits each has to offer and what facility situations they lend themselves to.

Mounting choices

Drop Rod

With a drop rod mount, flexibility is the biggest benefit offered. Used for both trussed track and plain track, a drop rod mount offers 360-degree rotation which allows the track to be installed in any horizontal direction. This makes the drop rod ideal fall protection mount for facilities with a lot of overhead space to work with. This mount also provides the advantage of allowing your workers to use shorter SRLs (self-retracting lanyards) by placing the track closer to the work area.

One key consideration is that drop rod mounting requires sway bracing.

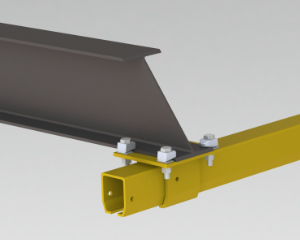

Flush Mount

The flush mount option for fall protection comes in two distinct variations, although either option is ideal for low-clearance situations. Both place the track directly against building support structures, and both are also used for trussed plain tracks.

The flush-cross option places the track perpendicular to support structures, while the flush-parallel option places the mount (you guessed it) parallel to the support structure. Which you choose for your flush mount is up to the needs of movement your workers will be operating under while using fall protection. Either option provides a secure mount designed to hold your equipment in place.

Specialty and wood beam mounts

Flush and Drop mounts are usually the top choices when it comes to fall protection equipment mounting, but some other options are available. One example is using a wood beam mount if that’s what you must work on within your facility. Designed for both plain and trussed tracks, wood beam mounts provide fall protection capabilities, but come with a couple of caveats. One is that they must have sway bracing for proper safety protection.

The other is when considering a wood beam mount you employ a local engineer to inspect and approve your existing beams after holes are drilled. Only then will you be sure your system will do its job.

In addition to the three mounting options discussed, there are also customized versions you can opt for as well. An example would be a bar joist custom design for those buildings that have bar joists overhead. With many considerations to choose from, talking to your material handling provider (like Cisco-Eagle!) about what would work for you is definitely the first step.

Download our catalog

At Cisco-Eagle, we pride ourselves on being a single source for your material handling needs with a long history of performance you can rely on. Because we also believe in empowering our customers with detailed information and options, we’re proud to offer the latest version of our company catalog.

Download the catalog today

Evan Fleishacker