Pallet Rack Safety: Policies and Practices

Systematic inspections, evaluation and repair

Operating a warehouse almost always means using pallet racks to take advantage of vertical space and organization of bulk storage. If they’re specified, installed and loaded correctly, racks are usually one of the most stable, effective and safest pieces of warehouse equipment. Because they carry heavy loads on vertical structures, racks should always be evaluated for safety and effectiveness. They’re stable, but that stability can be compromised by any number of factors.

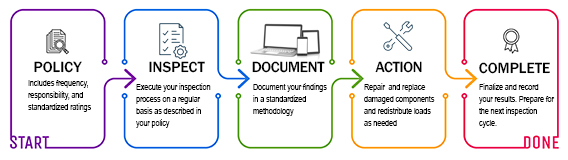

Have a policy for rack inspections

Let’s be blunt about it: if you have racks you should inspect them regularly.

You should document your inspection methodology, schedule and standards so that you always know what you need to do and when. What are your guidelines? What are your procedures? Who does the inspection?

Inspection frequency

- Rack inspection policies should be scheduled and periodic.

- Your inspection protocols may depend on the type of rack, the frequency of use and the traffic around it. If a rack is accessed frequently, it should be inspected more often.

- If your rack is in any setting where non-warehouse employees are nearby (like retail or public warehousing) it’s even more important to inspect and repair/replace frequently.

- Remember that unscheduled inspections should occur anytime an event happens. If you have a pallet collapse or forklift hit, that area needs to be evaluated as soon as possible.

Who should inspect racks

Typical warehouse employees or managers can do visual inspections, but only qualified engineers can do structural safety evaluations. Only a qualified structural engineer can tell you that a particular rack system or component is safe, but a warehouse manager can deem one unsafe due to damage.

Identify events that change the status quo

The goal of a visual inspection is to identify potentially dangerous areas: compromised uprights, damaged beams, bowing, out-of-square, etc. But damage is only part of the story. You’re also looking for things that change the rack, the activities around it and its load profile. The goal is to be aware of anything that triggers a change in the nature of the rack or storage operations. Rack damage or obvious issues with bowing or out-of-square installation are common.

More difficult to spot is a change in load density, shape or weight. If your inventory changes, how are the rack loads altered?

Good policies specify how often, the scope of the inspection and the type of inspector. These policies and procedures actually save time over extended periods.

Reporting should be systematic and standardized

- Inspection criteria should be documented: What are your inspectors looking for?

- Create standard forms for reporting damage. It’s important to establish consistent processes for not just how you inspect, but also how you document the results.

- How will you archive this information?

- And more importantly, how will you take action to correct deficiencies?

- Once you have done so, that should also be documented.

All of this sounds a little complicated, but organized, archived and actionable information is relatively simple to execute. A systematic, documented process not only helps you operate safer, it helps you comply with any local standards and can be extremely useful in case of an accident to prove your good faith in ensuring a safe warehouse.

Find and identify not just damage, but changes that can affect rack system safety – whether damage, changes or new rack layouts.

Rack inspection checklist

- How often will you inspect? Establish a schedule and stick to it.

- Who will inspect the rack, and for what deficiencies? Warehouse and EHS personnel can do visual and process inspections, but not structural.

- What materials, tools or equipment do you need? Do you need levels, flashlights, scissor lifts, cameras, measuring tapes, tablet computers, etc.?

- What types of inspection?

- Visual inspections: Search for apparent and visual damage and loose hardware.

- In-depth structural inspections: Evaluate the safety of rack components.

- Load suitability inspections: Has anything new been introduced to the warehouse? Was it evaluated before being racked?

- Process inspections: How is the rack being used, loaded and unloaded?

- Is your documentation standardized? Create documents, checklists and standardized forms for your inspection(s). Those should include a location system, date/day and notes. You can also create standardized checks (component damage types, bowing, out-of-square, etc.)

- Does your process document changes and fixes? When issues are addressed, add that fix to your documentation.

Use your inspection process as a training opportunity

Training is not necessarily part of an inspection process, but the process itself is a great opportunity to train people on the dangers rack can pose and ways to make themselves safer. Bringing forklift drivers along helps them understand the hazards and ways to avoid them. They should understand the reasons for loading methods, the placement of capacity labels and the need to report damage when it occurs.

Note: this article is general in nature and should be used for informational purposes. Always involve your EHS team and rack professionals when you evaluate racks for safe operation.

Read more

- Pallet Rack Load Distribution Guide

- Rack inspections and maintenance – from RMI (Rack Manufacturers’ Institute)

- Pallet Rack Evaluation: Safety

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners.

You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.