The Golden Zone Is a Moving Target: Slotting for High-SKU Warehouses

Fast, efficient picking is a lesson in SKU geography

Warehouse efficiency doesn’t fail all at once. Instead, operations slow down quietly. A few extra steps per order. A little more reaching. More waiting. Congestion forms up when you’re not thinking about it. Over time, the operation becomes heavier, less fluid, and more expensive without anyone noticing exactly when it happened.

In many cases, the cause isn’t labor, effort or faulty equipment. It’s geography.

It’s the slow decay of slotting discipline in environments where demand changes faster than the warehouse layout does. In high-SKU operations, where fast movers frequently appear and disappear, warehouse slotting has to stay in motion. If it doesn’t, the geography of your pick positions begins to work against your order pickers. They’re walking more, picking less. They’re straining to get things they should easily reach.

The ergonomic golden zone is not just a best practice. It’s a competitive advantage.

In volatile SKU environments, your ergonomic golden zone in good geography must be protected, treasured and treated as a moving target.

Defining high SKU counts: it’s complicated

The issue isn’t volume. Ten thousand SKUs, 50,000 or more can be static or very dynamic. The real challenge isn’t the number of SKUs; it’s how quickly velocity changes.

Some examples of higher volume SKUs are:

- Apparel is the classic example of a fast-moving SKU business. Sizes, colors, and seasonal swings create SKU intensity. A product that is a top mover today may become dead inventory in a matter of weeks. Even in fundamental lines like underwear and t-shirts, preferences, materials and sourcing can change.

- Consumer electronics and accessories are a prime example. New device releases can trigger sudden spikes in demand for chargers, cases, and add-ons, only for those SKUs to fade as quickly as they surged. Watch what happens when a new iPhone is released. Everything from cases to cables shifts along with it.

- Health and beauty products behave similarly, with endless variations by shade, scent, and formulation, driven by trends that shift faster than replenishment cycles.

- Automotive and MRO parts distributors also live in this world. Thousands of items may sit untouched for months until one part suddenly becomes critical and starts moving nonstop.

- This can also be true for aerospace MRO operations, where manufacturing changes and recalls can shift inventories quickly.

- Book and media fulfillment operations face massive catalogs and unpredictable demand spikes, where travel time becomes the dominant cost. Bestsellers come and go, along with market preferences.

- Seasonal merchandise is probably the most extreme case of all, where inventory peaks hard, then becomes obsolete the next day.

The common thread is simple: in these environments, static layouts cannot keep pace. Many modern distribution operations we haven’t touched on here at all face lightning-fast SKU churn and the picking chaos that can come along with it.

The golden zone and picking speed

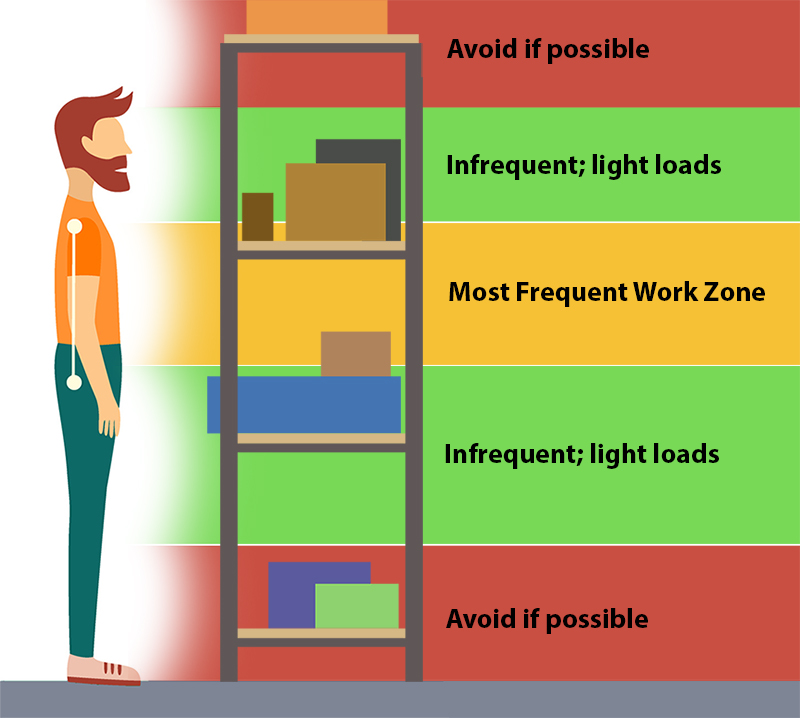

Most warehouse people understand the ergonomic golden zone is the area from waist-to-shoulder height where picking is fastest and least physically taxing. Picking the zone doesn’t cause people bend down, climb up, reach awkwardly, or awkwardly reposition. The motion is efficient and repeatable. But there is another golden zone: the one closest to the point of use. That zone reduces transit time for order pickers. Even in a pick & pass system, these zones can be closer or further from the conveyor line.

Read more: Improve Productivity with Ergonomic Storage System Design

In high-volume operations, small ergonomic advantages compound dramatically. A few seconds saved on a pick is not just a few seconds—it’s hours over the course of a shift and weeks over the course of a year. The golden zone is prime real estate because throughput lives there.

And yet, many warehouses are still slot-based on convenience rather than data. Items end up where they fit, where they were placed years ago, or where someone thought they belonged. The result is that hot SKUs become trapped in bottom locations, overhead reserve positions, or remote aisles far outside the primary pick zone.

What SKUs get the golden zone slots, and when do they get them?

Above: in this application, mobile flow racking is positioned along a manufacturing line. This allows the golden zone (both ergonomically and geographic) to move as parts needs or production runs change.

A fast mover is defined by its consumption rate—how frequently it is picked, how often it appears on orders, and how quickly it drains from its location. In volatile SKU ops, frequency can constantly change. SKUs can quickly go from very fast movers to dead items. And that creates a dangerous problem: yesterday’s winners continue occupying the golden zone, while newly hot SKUs are forced into harder-to-pick positions. This can be problematic for lower velocity operations, too. If an item slowly declines, the pain point is harder to spot.

Whether it happens in a day or 100 days, when it happens, pickers are handicapped from the minute they start working. They walk farther, reach more, bend more and waste time accessing the products that should be easiest to grab.

A silent productivity killer

Poor slotting is a slow bleed. Pickers walk hundreds of extra steps per day. Congestion forms in aisles. People are worn out from bending and reaching. Small delays that compound into missed shipping windows and rising overtime. Poor slotting can double or triple the distance traveled during picking. A static warehouse slows down and becomes less productive over time in ways that are difficult to notice until the cost becomes unavoidable.

When do you demote an SKU?

One of the most important concepts in slotting is also one of the most overlooked: managing empties: relocating SKUs that no longer qualify as fast movers from prime locations. It means treating golden zone slots as earned space, not permanent positions. Slow-moving or dead inventory allowed to linger in your best pick positions, steals productivity every day it remains there. Meanwhile, emerging fast movers are pushed into secondary positions, where every pick becomes slower and more disruptive.

Key takeaways

- High-throughput environments can cause congestion. If every top mover is placed in the same zone, congestion is inevitable. Pickers cluster in the same zones, traffic builds, and speed crashes out. The goal is to distribute your fastest-moving, most important products intelligently across golden zones to maintain flow.

- Consider dimensional data alongside pick rates. Slotting breaks down when you ignore product size and shape. A bulky fast mover can consume prime space that should hold multiple smaller high-frequency items. Combine SKU velocity with dimensional data to maximize space utilization while protecting throughput.

- Balance all the costs. Pickers grow used to certain storage positions, so automation that directs them is helpful (if expensive). Reorganization and the software you use to make these decisions are costly. But the cost of ignoring slotting is far greater. Poor replenishment forces pickers into reserve storage, onto ladders, or waiting for forklifts to retrieve pallets. Those interruptions can add 25 percent or more to pick time, especially in high-SKU environments where velocity shifts constantly.

- Slotting only delivers sustained productivity when it is treated as a cadence, not a project. Warehouses cannot afford to treat slotting as a one-time project. In volatile environments, slotting must become a recurring operational discipline. The warehouse must move as velocity moves. How often do you re-slot? It depends on how quickly things move and how adept you are at storage position evaluation. The right cadence lets you promote and demote items frequently enough that the slow creep of ineffective slotting.

- Slotting discipline collapses without replenishment discipline. Even perfectly positioned fast movers lose their advantage if pick faces are allowed to run dry. When replenishment is delayed or inconsistent, pickers are forced into reserve storage, climbing ladders, waiting for forklifts, or interrupting flow to retrieve product that should have been available at the point of pick.

High-velocity operations can’t afford static slotting

High-performing warehouses are not necessarily the ones with the most automation or the largest footprint or the best workforce, although all those things can help. They are the ones that maintain good geography. They treat slotting as an operational discipline, not a static layout decision. Don’t treat your golden zones as fixed locations or one-time optimizations. Great slotting is a moving target that must be protected and re-earned continuously. The golden zone cannot be treated as a fixed location or a one-time optimization. It is a moving target that must be protected and re-earned continuously.

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.