Options for Mobile Weighing Technologies in the Warehouse

Weigh and count "on the spot"

In dynamic distribution environments, accurate, fast weighing, counting, and dimensioning systems are more important than ever. This is particularly true in 3PLs and other operations where needs often change. Getting it right, and getting it quickly has become increasingly more important. One way is to utilize the newer mobile weighing systems on the market today.

Within efficient supply chains, products must arrive just in time and in correct amounts-by weight, count, or volume. How can you check? Mobile, battery-powered scales have driven changes in weighing processes in many warehousing, distribution, and manufacturing environments. These scales can be quickly located in the most effective areas to optimize facility process improvements and reduce the number of scales needed.

Why should you deploy mobile weighing technologies?

- Flexibility: Mobility allows mobile weighing to easily meet changing distribution and assembly layouts

- Efficiency: Reduce product touchpoints

- Easy relocation: Relocate your scale instantly, without the need to recalibrate

- Ergonomics: Reduces manual product handling

- Battery: Extended battery life, safe dc operation are important

- Wide range of applications: Scales are available that can weigh containers, pallets, drums, cases, loads on hand trucks, and more

- Durability: Get scales that are designed for abusive mobile applications

Applications include material handling, inventory control, shipping & receiving, warehousing, order fulfillment, cross-docking, and uses in security-sensitive environments. We can help you configure your mobile weighing solution to work within your system and for your application.

Mobile weighing systems: options

For instance, pallet jack scales let you weigh and transport your load right on the pallet (whether it’s going out or coming in). Because an accurate weight can be taken of an entire shipment, you don’t need to calculate shipments by individual product weights, plus pallet weight, plus dunnage. It’s a serious time-saver.

You can utilize mobile power carts to make your counting and small parts scales mobile. Since the cart has integrated power sources, you take it to the point of weighing rather than transporting parts to other areas of the facility to central weighing points.

Right: powered mobile cart with the ability to host a scale for various weighing and counting functions

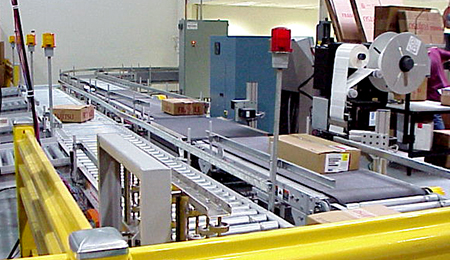

Integrated conveyor scales

In-line conveyor scales are also a factor. If you can weigh loads on a conveyor line, that removes the need to add people and processes elsewhere. You can convey picked orders directly to a shipping or packaging function for completion. Conveyor scales also serve critical error-detection functions by alerting you to picked orders that may be out of standard for your parameters. While conveyor scales aren’t “mobile”, they do serve a similar function by delivering the load directly to the scale without human intervention.

Tags: warehousing, Material Handling, scales, industrial weighing systems, inventory accuracy

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.