Don’t Climb that Pallet Rack!

It's one of the most dangerous things you can do in a warehouse

To save time, people sometimes climb pallet racks to pick orders or do other things. This should never happen. While it’s faster to climb than it is to bring a rolling stair ladder or a forklift in to do it right, it’s dangerous and counterproductive. Do it long enough and there will be injuries.

Racks aren’t designed for climbing

They lack guarding and handholds suitable for it. Pallets are both sharp and not suitable for handholds; they can have broken planks, protruding nails, and fractured stringers that can give way under a person’s weight or puncture a hand looking for a hold. Pallets that aren’t loaded fully may shift or slide, causing a fall.

For a busy order picker, it’s tempting to climb up and get that one needed box when the floor level pallet is spent.

If someone climbs a beam level high and steps on either the wire deck or on an improvised deck of loose boards or an empty pallet, there is a risk of a foot slip that can cause a fall or cause a live load to shift and fall with the worker.

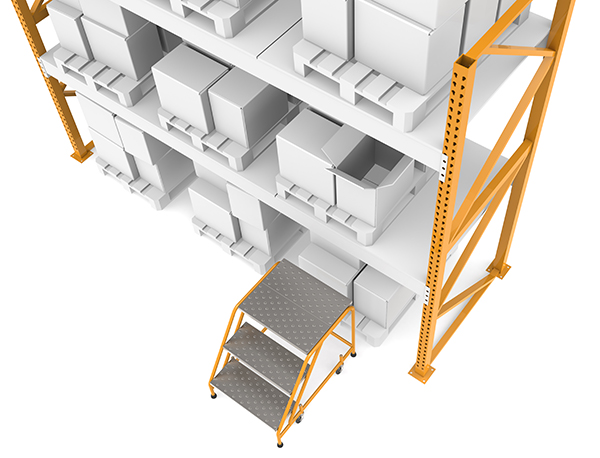

Use the right ladder

Rolling ladders are relatively inexpensive and take little time to move and use. Make sure they are readily available for aisles where carton or piece picking can occur on upper rack levels. However, this isn’t the safest method. In very few instances should case picking of pallets above eye level. Those pallets should be for bulk storage only. This results in employees who cut shrink wrap to access cartons from a bulk pallet when the best way is to bring that pallet down to the floor level.

Utilize forklifts to access palletized loads to bring down for safer picking. For loads where cartons from the back of a pallet must be accessed, this is the preferred method. If you’re using a platform ladder and the order picker must access items as deep as four feet into the rack, you risk him stepping off the platform and onto the decking or the pallet itself. Neither is a safe way to operate.

Ways to discourage rack climbing

- Install rack safety nets or guarding on the outside of the bay. That doesn’t stop climbers on the pick aisle, but it can help discourage them in some places.

- Make rolling ladders easily accessible. Don’t force order pickers to walk a long way to get one. They will take the path of least resistance if it’s time consuming to get a ladder. Similarly, if you are picking pieces off elevated pallets, make forklift or power stacker access easy for warehouse workers.

- Make sure that you are actively discouraging the process by posting “Do Not Climb” signs on the rack

- Train and re-train workers on the dangers. Discipline when someone is caught climbing.

- Be sure the aisles aren’t cluttered. This can discourage people from using the right method to access upper level pallets.

Download our Pallet Rack Guide

Pallet rack enhances your warehouse and improves overall facility performance when correctly specified, laid out and installed for the right load in the right positions. Check out our guide to specifications, styles, accessories and applications with expert tips from our employee-owners.

You’ll find quick, useful information on racks and how you can use them more effectively.

Download the guide today

Tags: warehouse rack, plant safety, Safety & Ergonomics

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.