Every company that operates forklifts struggles with pedestrian safety problems. The issues are well-documented; forklifts are often the most problematic safety machinery in any operation that utilizes them.

Every company that operates forklifts struggles with pedestrian safety problems. The issues are well-documented; forklifts are often the most problematic safety machinery in any operation that utilizes them.

Tags: plant safety, forklift safety, forklift

Posted in Forklift - Pedestrian Safety|

With OSHA statistics showing that every year more than 100 workers are fatally injured of suffering disabling injuries in ladder-related accidents, it makes sense to take time in your facility to educate and train workers on safe ladder operation procedures. This month, the American Ladder Institute (ALI) is sponsoring its annual National Ladder Safety Month to promote ladder safety at work and home.

Tags: worker safety, safety training, facility safety, safety issues, warehouse accidents, warehouse, plant safety

Posted in Safety & Ergonomics|

With the rising costs of workers’ compensation insurance and global pressures to increase productivity, warehouse and distribution center managers are taking a much closer look at improving ergonomics. With as many as 65% of worker’s compensation claims associated with manual materials handling, insurance companies are raising their rates—or mandating ergonomic improvements for continued coverage.

Equipment suppliers are responding to the need, engineering and designing features into their products to help workers minimize the strains associated with lifting, reaching, twisting, pulling and pushing. These new product features can also help address the demand for increased productivity as well.

Tags: Material Handling, order fulfillment, warehouse safety, ergonomics, plant safety, Order Picking & Fulfillment, Safety & Ergonomics

Posted in Safety & Ergonomics|

Adjustable workstations make operations like packing, picking, assembly and inspection safer, more comfortable and more productive because they easily let operators work in the ergonomic “golden zone” suitable for their own needs – the same station can be used by someone 6’4″ as someone 5/2″ on multiple shifts, or if the load or work varies in height, like multiple sized boxes or various motors that may be different sizes. These workbenches are adjustable, usually by crank or by powered switch or pushbutton. What might suit you best?

That said, having to utilize a crank to adjust the height is inherently counter to the fundamentals of ergonomics, and it’s slow. To combat this, consider electric adjustable workstations, which provide multiple advantages over their cranking counterparts.

Tags: Warehouse Management, warehousing, warehouse, workstations, ergonomics, plant safety, forklift safety, Safety & Ergonomics

Posted in Storage, Organization & Workstations|

ISNetworld is a global resource for connecting corporations with safe, reliable contractors/suppliers from all types of industries. ISN collects self-reported safety, procurement, sustainability, quality and regulatory information from contractors and suppliers, verifies its accuracy, and then reports the results in an easy-to-follow format. This allows corporations to select companies that best meet internal and governmental requirements, while providing contractors/suppliers the opportunity to centralize their conformance information, saving time and gaining presence in the marketplace.

Tags: facility safety, safety issues, warehousing, Material Handling, warehouse safety, warehouse, plant safety, forklift safety, worker safety

Posted in Safety & Ergonomics|

According to the American Ladder Institute (ALI), every year more than 300 fatalities in ladder-related accidents. Thousands more suffer disabling injuries. That’s why the ALI has declared March National Ladder Safety Month – the organization wants to raise awareness of ladder safety. As you plan ahead for the coming month, consider using March as a time to emphasize ladder safety among your workers.

Ladder-related citations are frequently among the top 10 most frequently cited safety violations, according to the Occupational Safety and Health Administration (OSHA), currently ranking number 7 overall. Make sure you’ve created a safe work environment in your facility for ladder safety.

Tags: safety issues, warehouse accidents, warehouse, plant safety, worker safety, safety training, facility safety

Posted in Safety & Ergonomics|

Tags: warehousing, shelving, plant safety, Inventory protection

Posted in Storage, Organization & Workstations|

Above: a driver security cage, which allows entry into a dock area door, but restricts access within the facility

It’s difficult enough to handle the people who are supposed to be in your plant every day, much less visitors. Even those you invite.

The problem has two components: safety and security. From a safety standpoint, you have no idea how an untrained guest might behave. That guest may not know which machines are dangerous. He may not know to use your specified pedestrian walkways, wear steel toe boots, or stay clear of running conveyors. He doesn’t have your safety training. From a security standpoint, guests can be problematic from a number of angles. A plant visitor who has access to storage areas has access to inventory. With even the cheapest of phones now having good cameras and video built in, a guest may photograph something you don’t want made public. That guest could also damage something, accidentally or otherwise. There are lots of wrinkles.

Tags: Industrial Security, plant safety, Safety & Ergonomics

Posted in Security|

Check out this video from ESH Safety News America for some common ways people fall in a variety of situations. The video is informative, and sometimes funny (see the shovel part), but the consequences of a slip & fall accident certainly are no laughing matter.

Tags: industrial accident prevention, plant safety

Posted in Safety & Ergonomics|

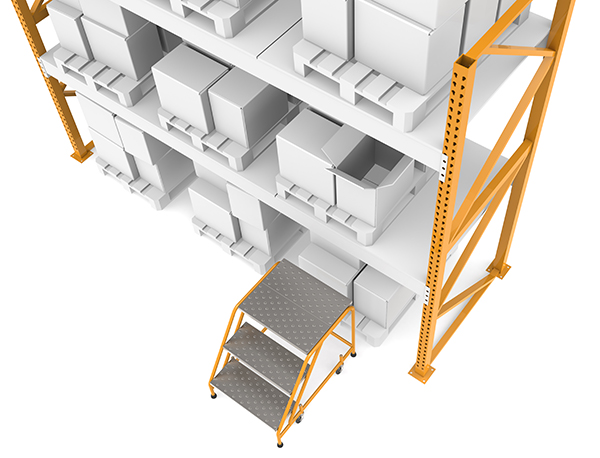

To save time, people sometimes climb pallet racks to pick orders or do other things. This should never happen. While it’s faster to climb than it is to bring a rolling stair ladder or a forklift in to do it right, it’s dangerous and counterproductive. Do it long enough and there will be injuries.

Tags: warehouse rack, plant safety, Safety & Ergonomics

Posted in Pallet & Warehouse Racks|