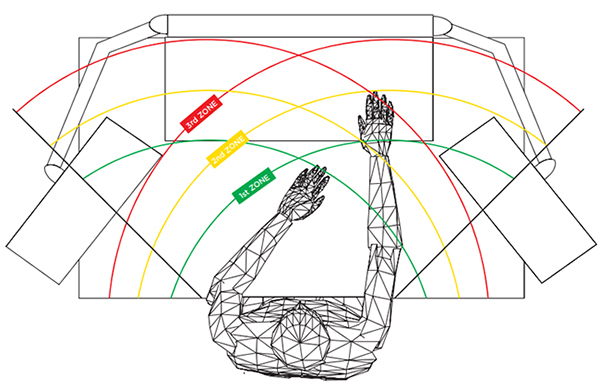

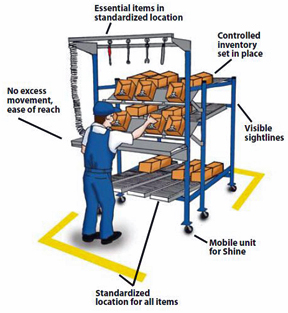

You should always analyze the economy of movement for repetitive tasks like assembly, packing, picking and repair. Imagine reaching to the same shelf, for the same carton, to pull the same part. How many times a shift does someone make that reach? How many working days a year? How many years? Shaving time and effort off a simple repetitive motion can shave time off your process and improve ergonomics over the years.

To do that, look at how many times–and places–your people reach for things on a daily basis.