Workstation Ergonomics: Eliminating Extreme Movements

Extreme movements can be damaging: design your work processes to eliminate them

With the massive worker compensation costs related to musculoskeletal disorders, finding ways to reduce the risks is imperative. In May, we discussed the impact of work positioning. This time, the focus on the effects of extreme movements and how to counteract the risks.

This is the second part of our series on the effect of workstation ergonomics on work-related musculoskeletal disorders. Jeff Hoyle, Director of Ergonomic Services for North Carolina State University, and Robert Doucette of BOSTONtec discussed these issues at Modex 2020. Their presentation can be found here.

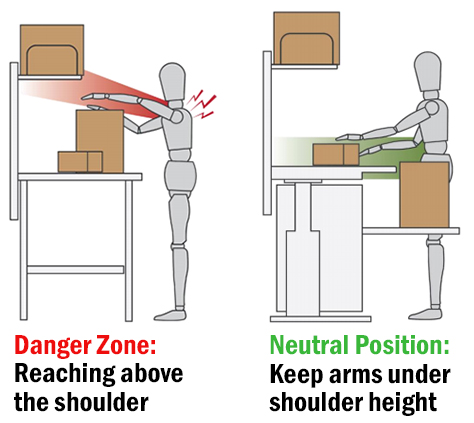

Reducing movements above the shoulder

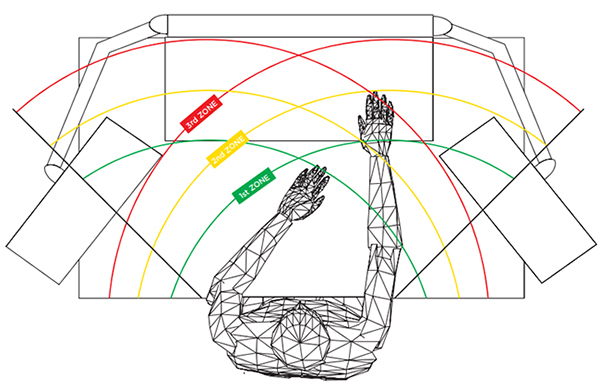

Movements above the shoulder are not recommended on a daily work basis. Good ergonomics practice is to always keep lifting within the comfort zone between your hips and shoulder height.

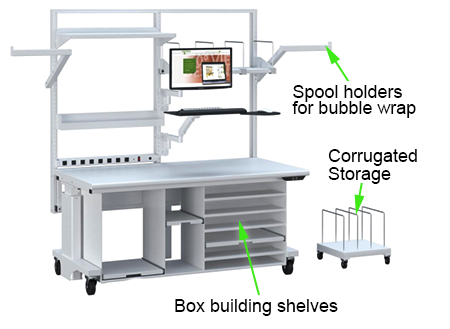

Above: workstation with pull-out shelves label troughs, monitor arms and other accessible functions that help workers to keep their movements within neutral zones. Courtesy of BOSTONtec.

An example is box building and loading. Many times these are relatively small boxes, and are often in the same size range, but sometimes there are larger boxes—one or two larger sizes that may not fit on the working surfaces. For small and medium boxes, many workstations are ergonomically fine.

When there is a larger box, there may be times when the worker must reach up and over the top of a tall box, which causes the packer to lift their arm above the shoulder—an extreme movement that can directly affect ergonomics.

Try to observe the 10:1 ratio for every lift performed. This means that a 10-pound object requires 100 pounds of back pressure to lift. Limiting these types of lifts will always help reduce strains and injuries.

To combat this, and keep the shoulder in a neutral position, the under-shelf box building table lets the packer build their box at a neutral and comfortable working height. They’re not reaching over their shoulder. Aside from the ergonomic benefits, the packer can have greater visibility into the large carton for accuracy and better product arrangement. Many of these box shelves can slide back into the workstation so that they don’t take up space until needed.

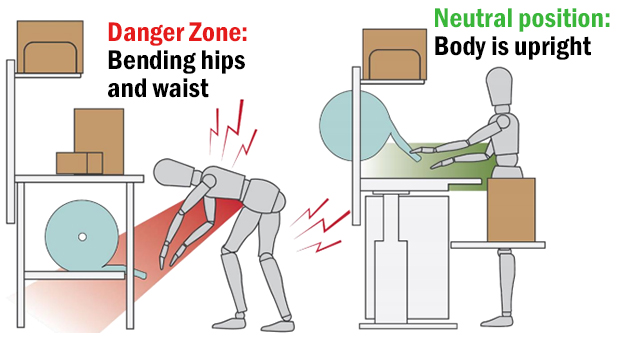

Don’t store packing materials beneath the work surface

Whenever packers must access materials (such as labels or bubble wrap rolls) beneath the work surface, they’re forced to bend down to access the materials, which is one of the most problematic work positions, particularly if any weight or physical manipulation below the waist is involved.

Above: Box building shelves slide out so that any box of the right height can be placed on them for packing or arrangement, without forcing people to reach over the top of a tall box on the work surface. This helps reduce bending at the hips and awkward arm positions.

Moving these materials to a neutral position that doesn’t force a bend, stretch or reach is ideal. In the example above, bubble wrap can be mounted on a spool above the table surface. Workers no longer have to reach above or below the work surface to access the wrapping materials.

The idea is to move anything that doesn’t need to be on the surface off it, in an ergonomic manner

Final thoughts

Ergonomics isn’t an exact science, and requires the active participation of workers, management and process design. Most every industrial operation can find ways to enhance its physical ergonomics and reduce stress and injuries. While workstations are a critical way to reduce these issues, other factors, such as conveyor ergonomics, working in rack aisles and more can contribute to a more productive, safer operation.

Tags: workstations, ergonomics

Scott Stone is Cisco-Eagle's Vice President of Marketing with 35 years of experience in material handling, warehousing and industrial operations. His work is published in multiple industry journals an websites on a variety of warehousing topics. He writes about automation, warehousing, safety, manufacturing and other areas of concern for industrial operations and those who operate them.